Horizontal machine for loading and compressing garbage

A compressor and garbage technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of incompact compaction and insufficient loading capacity, and achieve the effects of increasing loading capacity, improving shipping efficiency, and convenient and hygienic dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

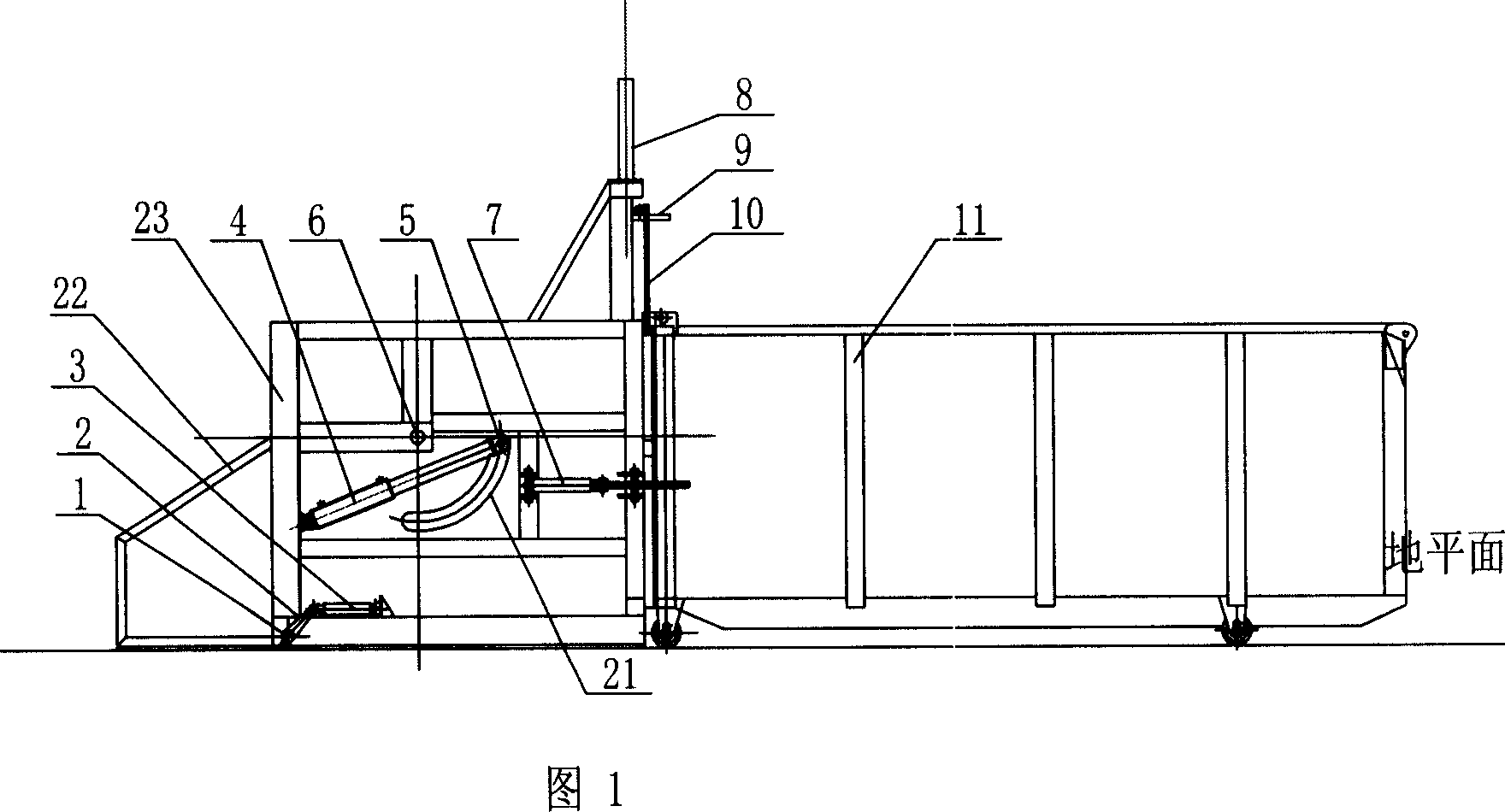

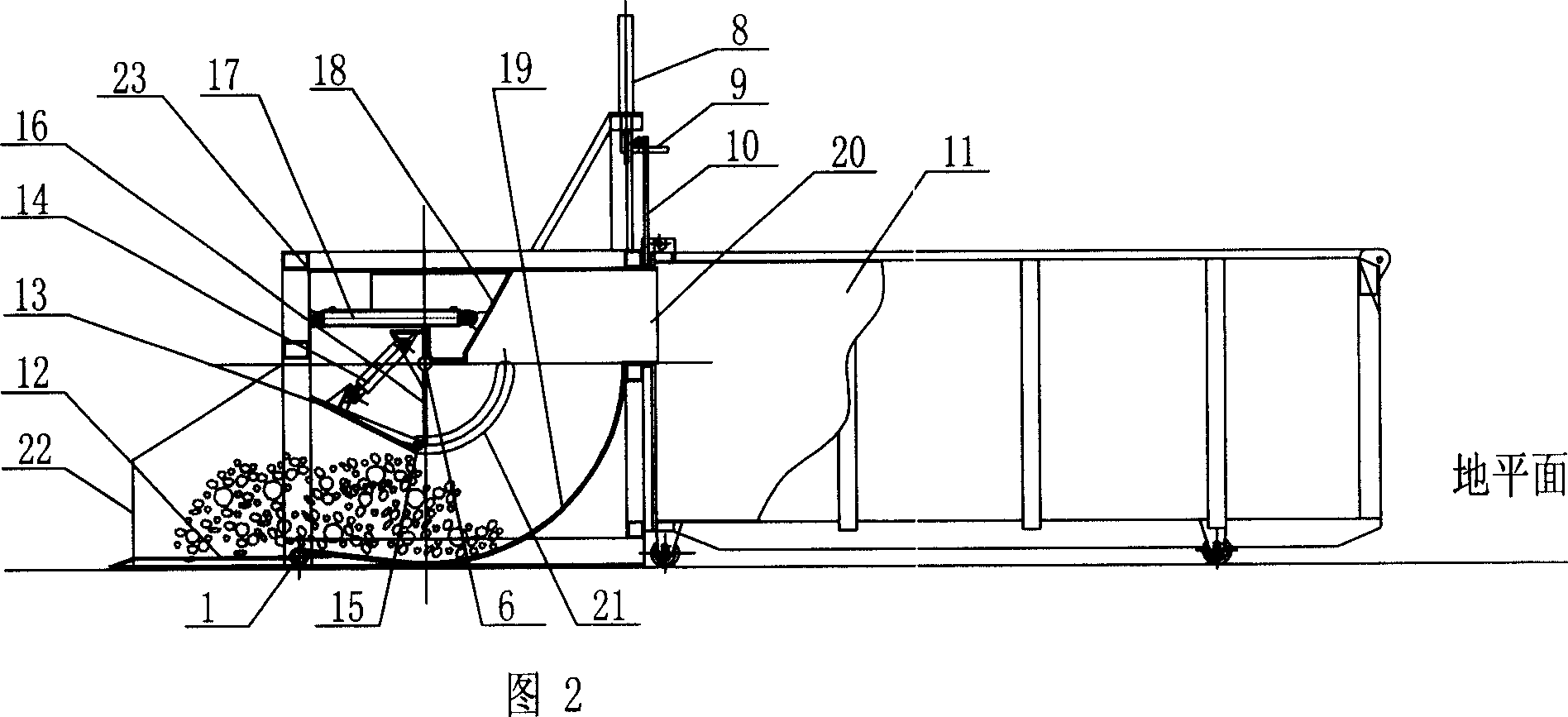

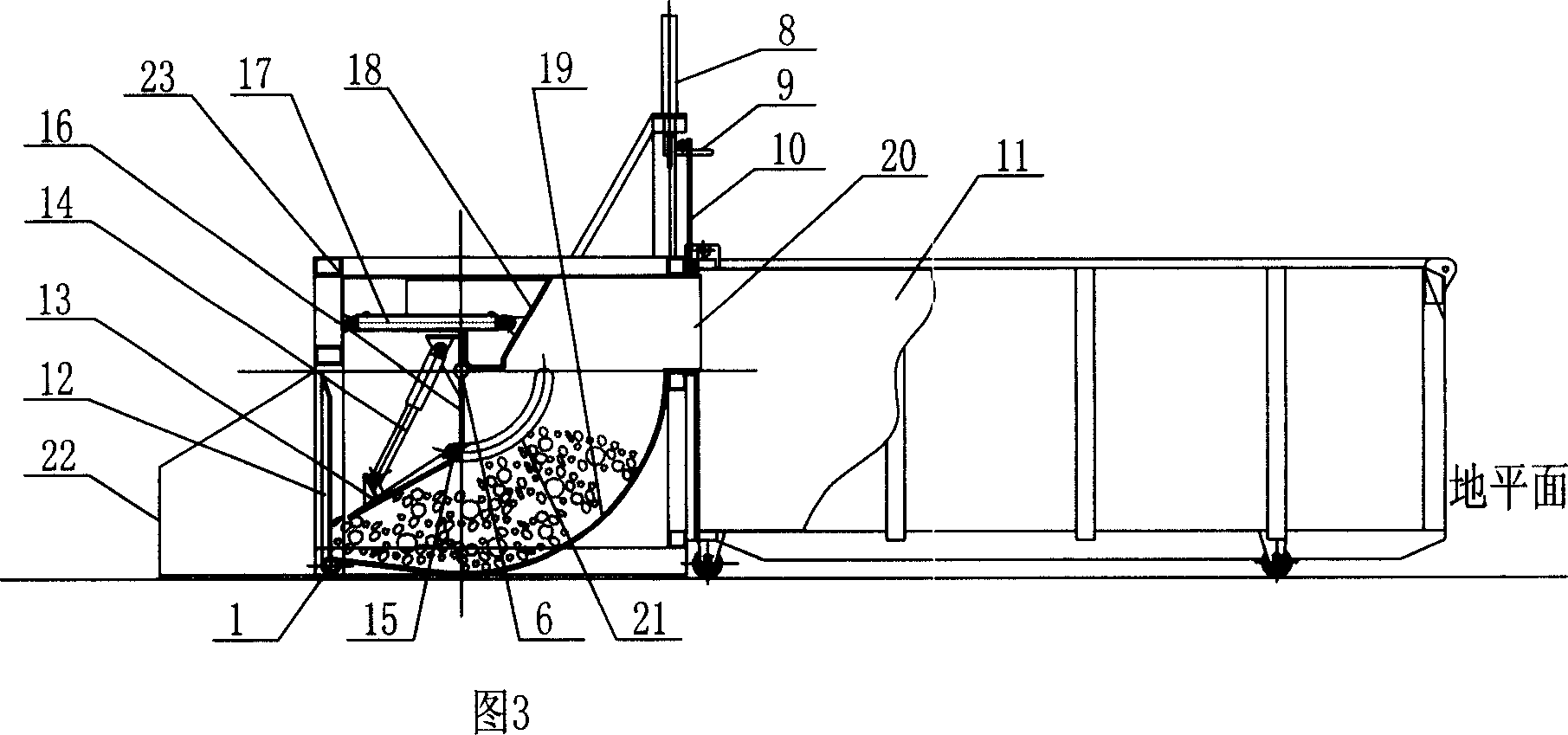

[0039] As shown in Figure 1, the compressor is loaded with horizontal garbage, and the detachable garbage bin 11 and the compressor box 23 are relatively tightly hugged and fixed by the locking mechanism 7 installed on both sides of the compressor box 23.

[0040] Garbage loading and unloading left and right baffles 22, loading plate rocking arm rotating shaft 1, loading plate rocking arm 2, loading plate oil cylinder 3 are arranged on both sides of the left end of the compressor box 23, and auxiliary garbage loading plate 12 is set near the ground on the left end of the compressor box 23. Garbage loading and unloading The left and right baffles 22 are fixedly connected to the compressor box 23, one end of the loading plate oil cylinder 3 provided on both sides is hinged to the compressor box 23 and the other end is hinged to the loading plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com