Air bubble pad decompression boat

A bubble pad and hull technology, applied in the field of electromechanical, can solve the problems of increasing the overall weight of the power supply system, increasing the failure rate, complex structure, etc., and achieve the effect of increasing the traveling speed, reducing the transportation cost and reducing the forward resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

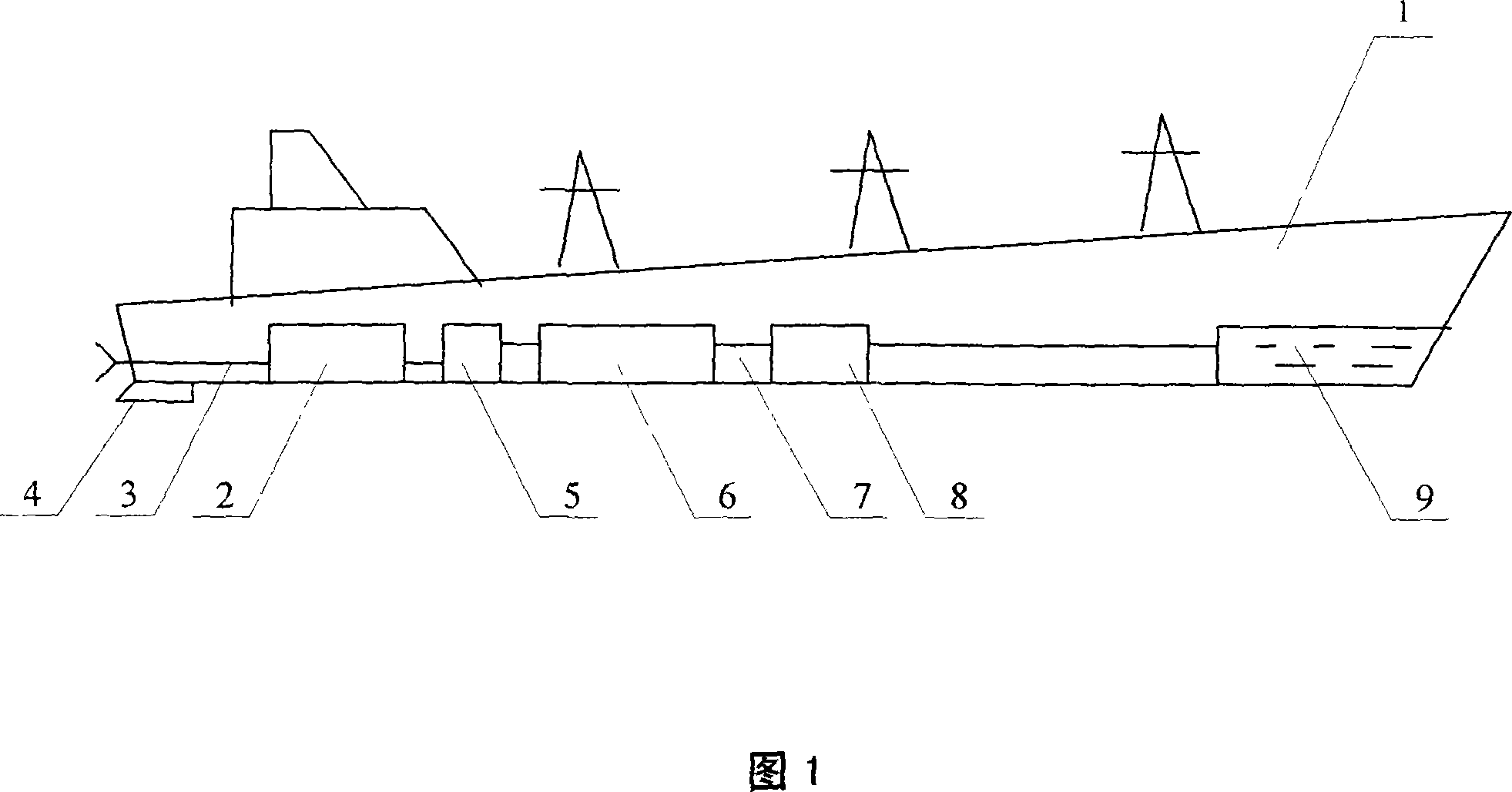

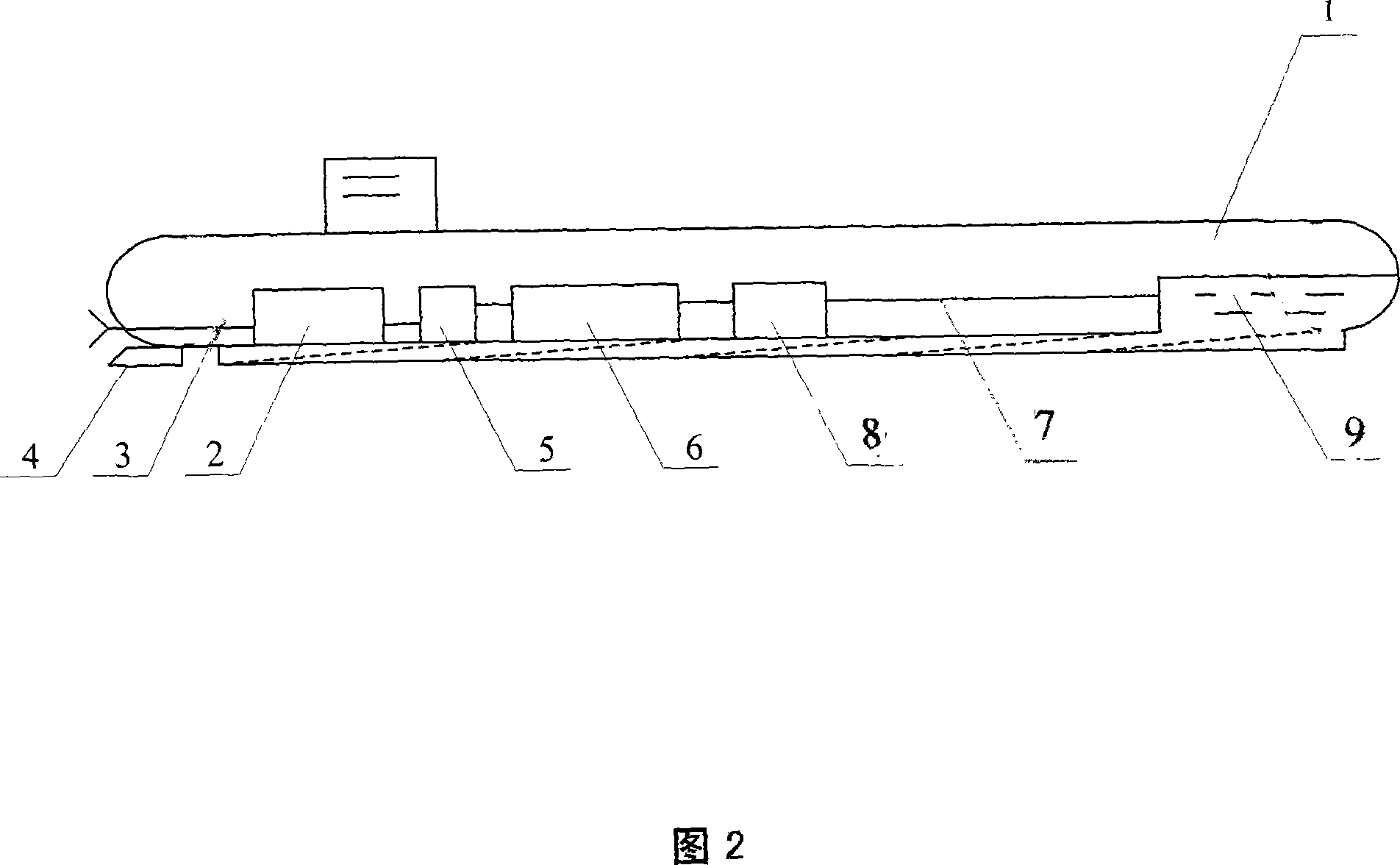

[0009] As shown in accompanying drawing 1, the present invention is made up of hull 1, engine 2, drive system 3, direction control system 4, air blower 5, air storage tank 6, air supply pipe 7, air supply controller 8, bubble generation device 9, Wherein, engine 2, drive system 3 and direction control system 4 are provided at the stern of hull 1; blower 5 is provided at the front of engine 2, and blower 5 is connected with air storage tank 6 through air supply pipe 7, and air storage tank 6 passes through The air supply pipe 7 is connected with the air supply controller 8, and the air supply controller 8 is connected with the bubble generating device 9 through the air supply pipe 7;

[0010] When the ship is moving, the blower 5 delivers compressed air to the air storage tank 6 through the air supply pipe 7, and then adjusts the air supply volume by the air supply controller 8, and delivers compressed air to the air bubble generating device 9 through the air supply pipe 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com