A method of shield machine combined freezing and strengthening stratum

A shield machine and stratum technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem that the penetration of reinforcement slurry cannot be effectively guaranteed, the quality of reinforcement cannot be accurately and comprehensively detected, and the temperature and strength of the frozen body do not meet the design requirements. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

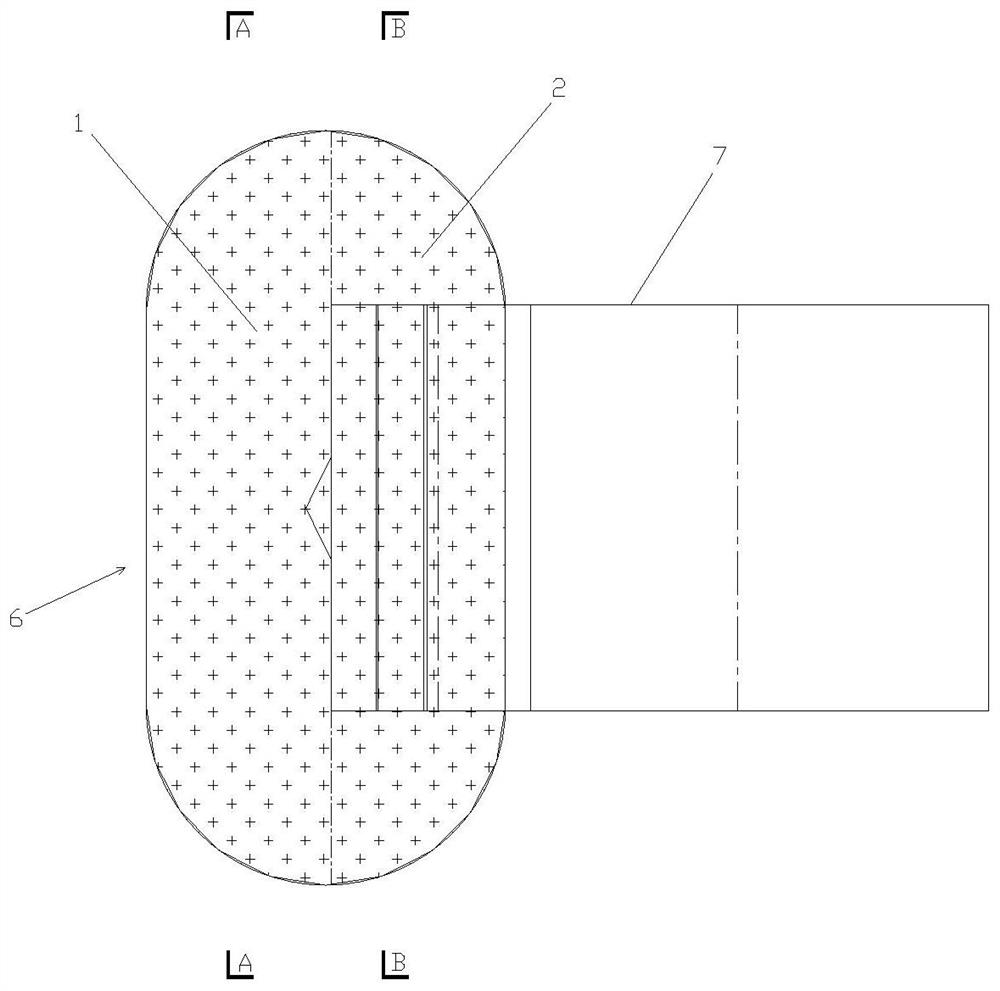

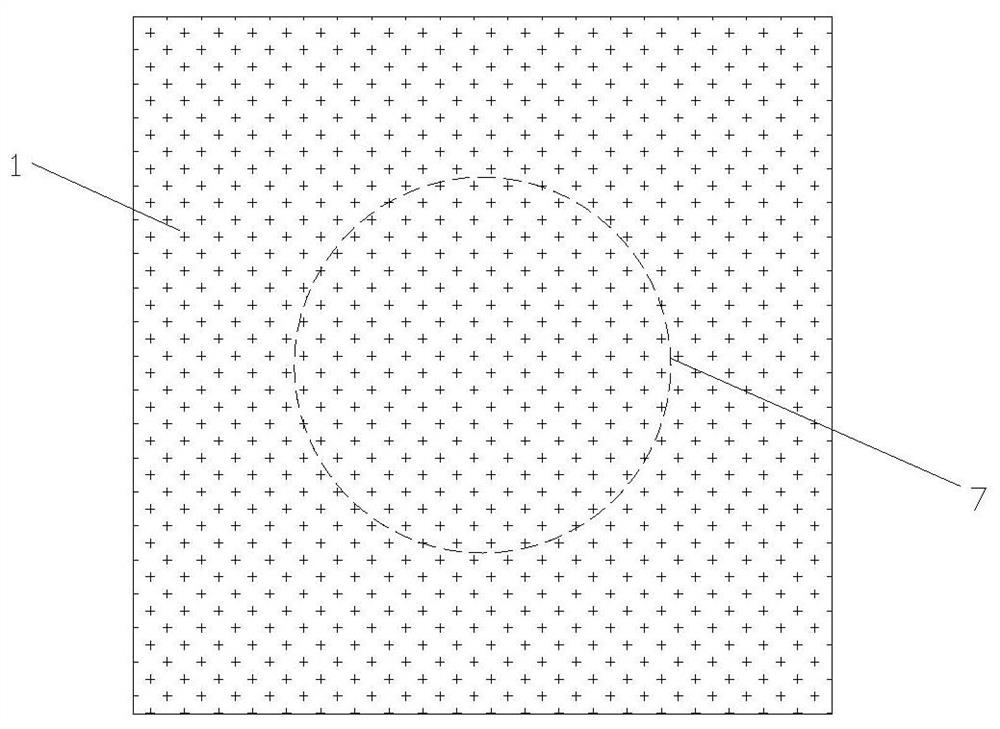

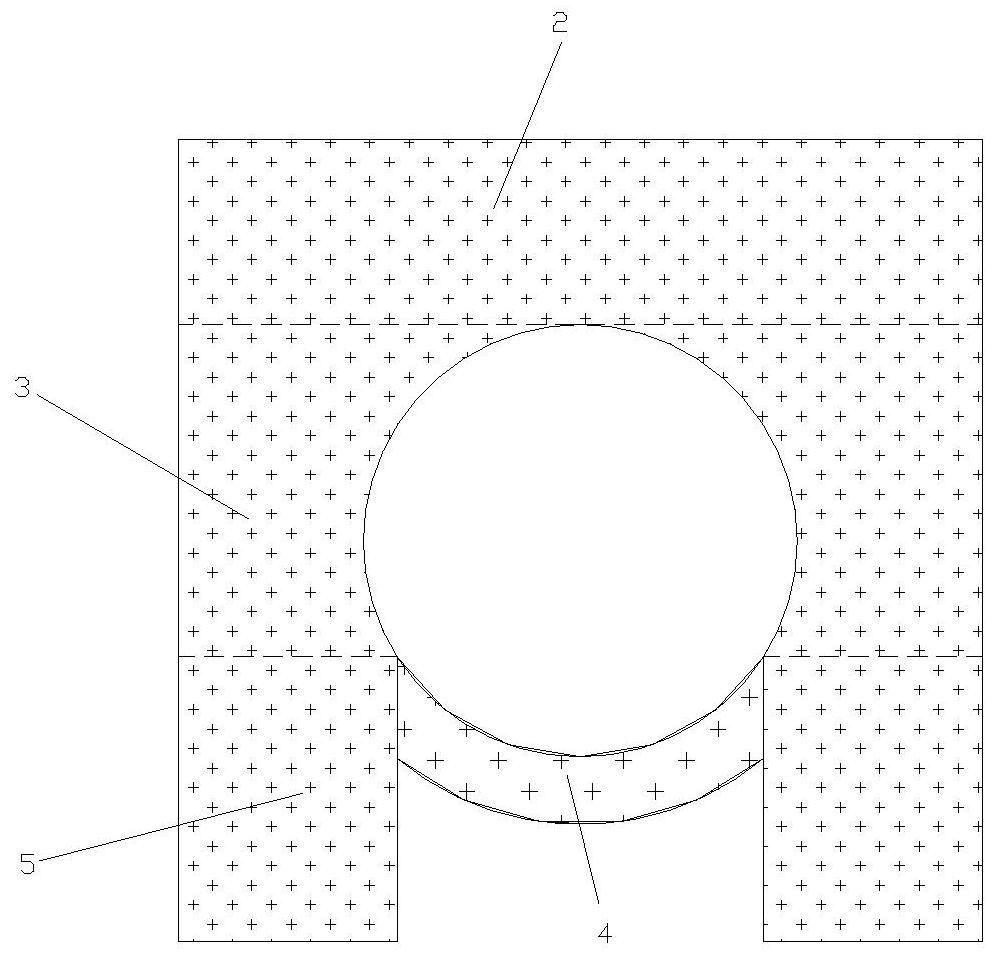

[0118] like Figure 1 to Figure 5 , Figure 9 , Figure 10 , Figure 11 Shown is a shield machine combined freezing and strengthening stratum method, the method includes the following steps:

[0119] Step 1, preparation of low-temperature frozen water:

[0120] Step 101, mixing calcium chloride and tap water at normal temperature according to the mass ratio (3-3.5): 7 and stirring evenly to prepare mixed brine;

[0121] Step 102, sending the uniformly stirred mixed brine into a freezer for cooling to obtain low-temperature frozen water;

[0122] Step 2. Set the freezing area of the cutter head of the shield machine:

[0123] Step 201, setting the freezing area 6, the freezing area 6 includes the front effective freezing area 1 located on the front side of the shield machine 7, the top effective freezing area 2 located at the top of the shield machine 7, and the surrounding area located on the side of the shield machine 7. The side effective freezing area 3, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com