Drinking bottle with ventilation structure

A drinking bottle and bottle body technology is applied in the field of drinking bottles with a breathable structure, which can solve the problems of increasing the difficulty of the product, affecting normal use, and being airtight, achieving the effects of low production technical requirements, reduced production costs, and overcoming water pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

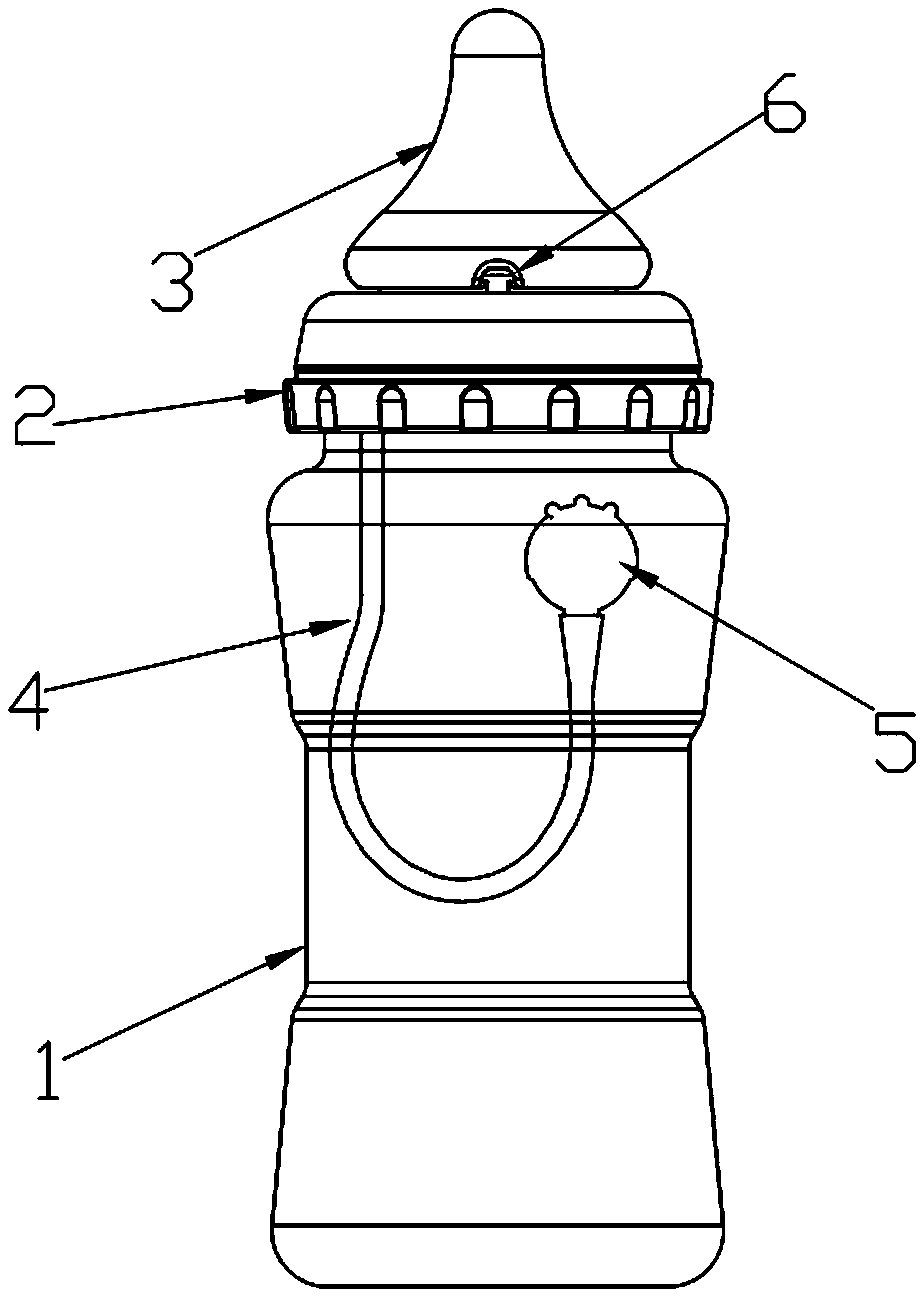

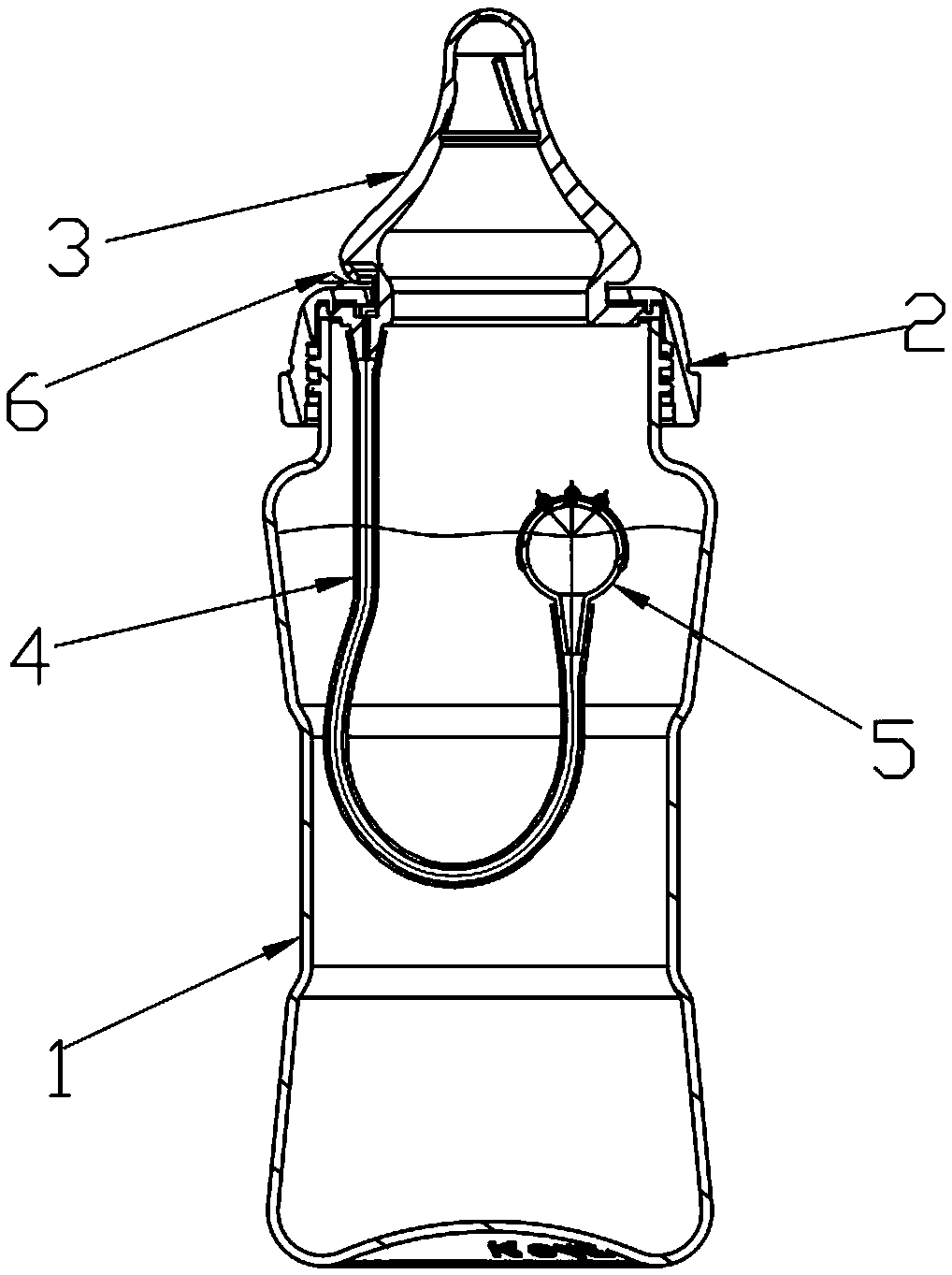

[0042] This example refers to Figure 2 to Figure 7 , the drinking bottle with breathable structure of its concrete implementation comprises bottle body 1 and bottle cap 2, the inside of bottle body 1 is the cavity for containing beverage, and bottle cap 2 is sealed and screwed on the opening of bottle body 1, and bottle cap 2 includes an air inlet 6 for entering air and a drinking nozzle for sucking out beverages. This embodiment uses a baby feeding bottle as an illustration, wherein the drinking nozzle is the nipple 3 of the baby feeding bottle, and the air inlet 6 is arranged at the bottom of the nipple 3. bottom side.

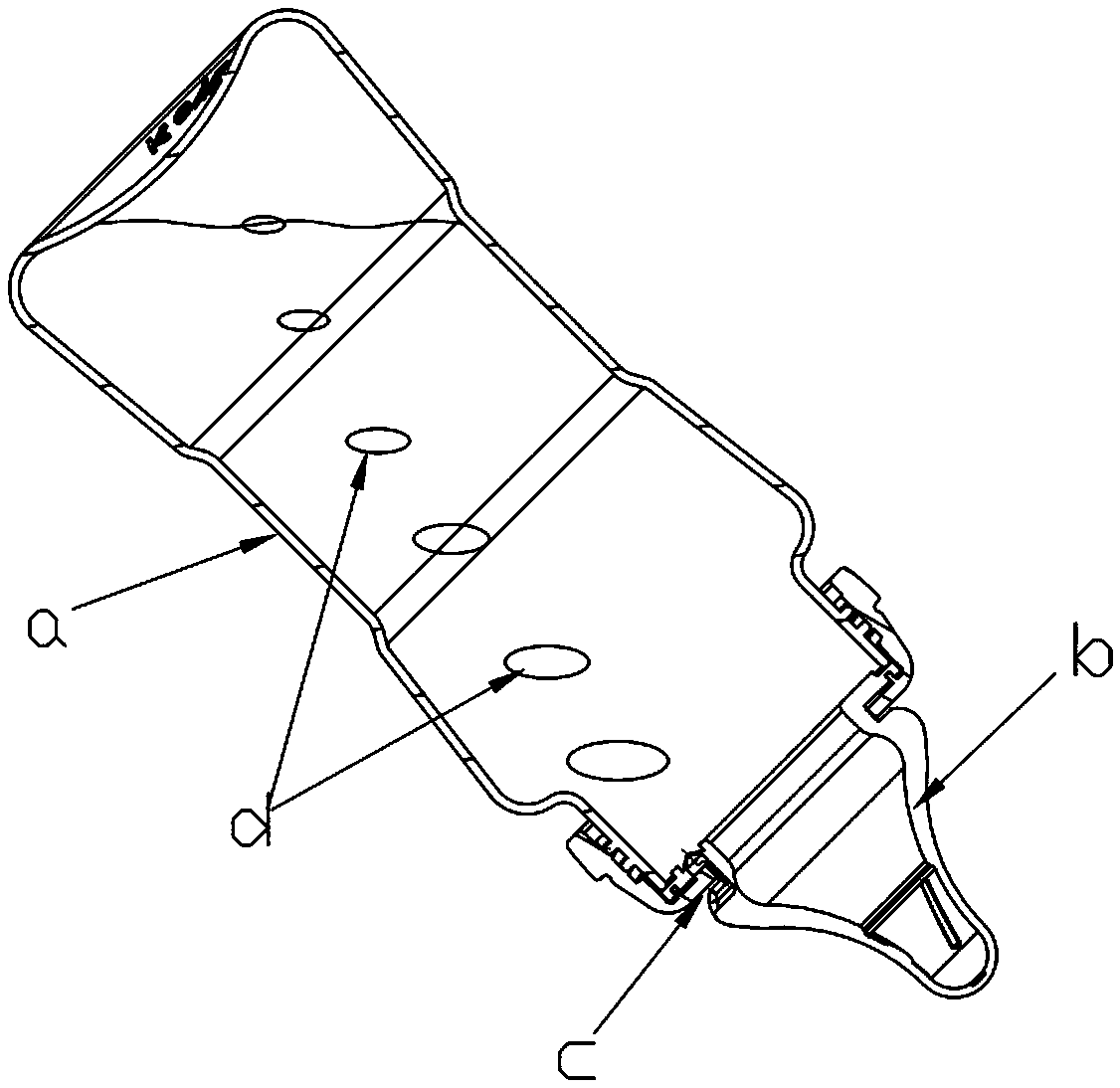

[0043] Different from traditional baby feeding bottles, there is a ventilating structure in the cavity of the bottle body 1, the venting structure includes a soft silicone tube 4 and a hollow floating ball 5, one end of the soft silicone tube 4 is connected to the air inlet 6, The other end of the soft silicone tube 4 is conductively connected with the hol...

Embodiment 2

[0047] In this embodiment, refer to Figure 8 and Figure 9 , the difference from Embodiment 1 is the shape of the air outlet check valve, the air outlet check valve includes a rubber sleeve 8 and a raised valve 9, the raised valve 9 is in the shape of a truncated triangular cone, and the slice cutout 10 is located on the truncated triangle The top surface of the shape is also directly cut quickly by a thin blade, which is closed in a natural state.

Embodiment 3

[0049] In this embodiment, refer to Figure 10 and Figure 11 The difference between it and Embodiment 1 lies in the structure of the air outlet check valve. The hollow floating ball 5 has an integrated structure, which is spherical as a whole. The air outlet check valve is an umbrella valve 11, and the bottom of the umbrella valve 11 penetrates and clamps On the top of the hollow float 5, and the top surface of the umbrella valve 11 is a fitting surface that is flush with the top surface of the hollow float 5, and the fitting surface is an arc matched with the top surface of the hollow float 5. shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com