Part assembling hole design system and method

A technology of parts assembly and design system, applied in computing, special data processing applications, instruments, etc., can solve problems such as low design efficiency and achieve the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

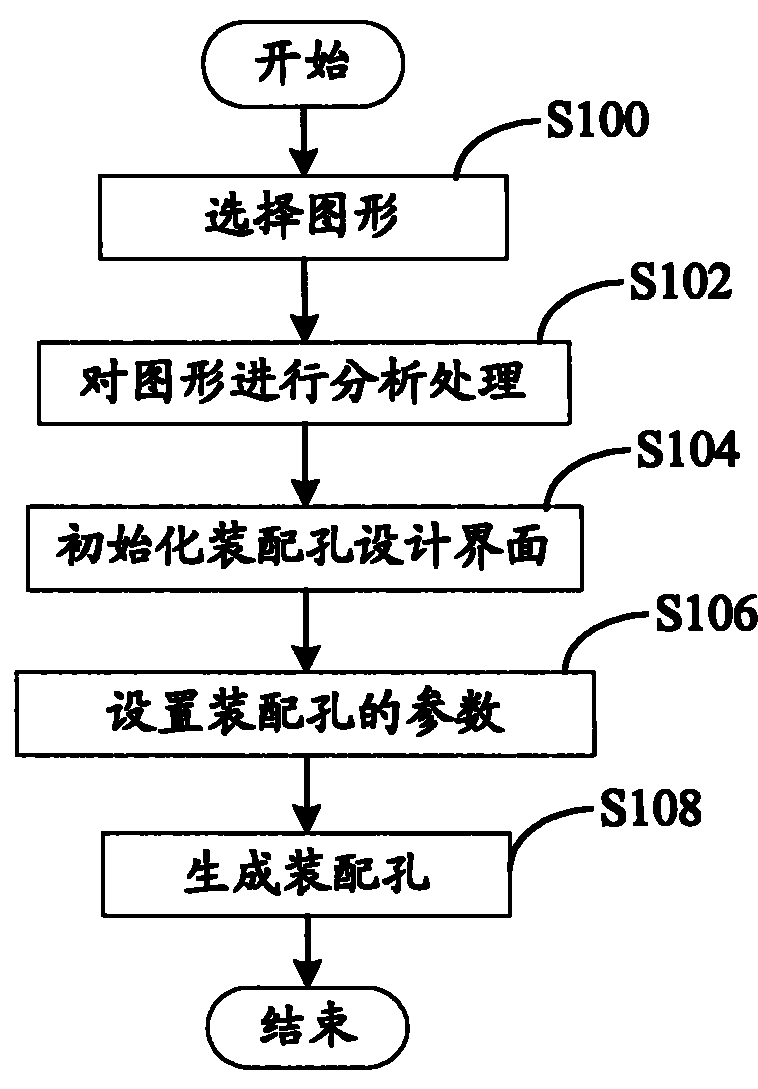

Method used

Image

Examples

Embodiment Construction

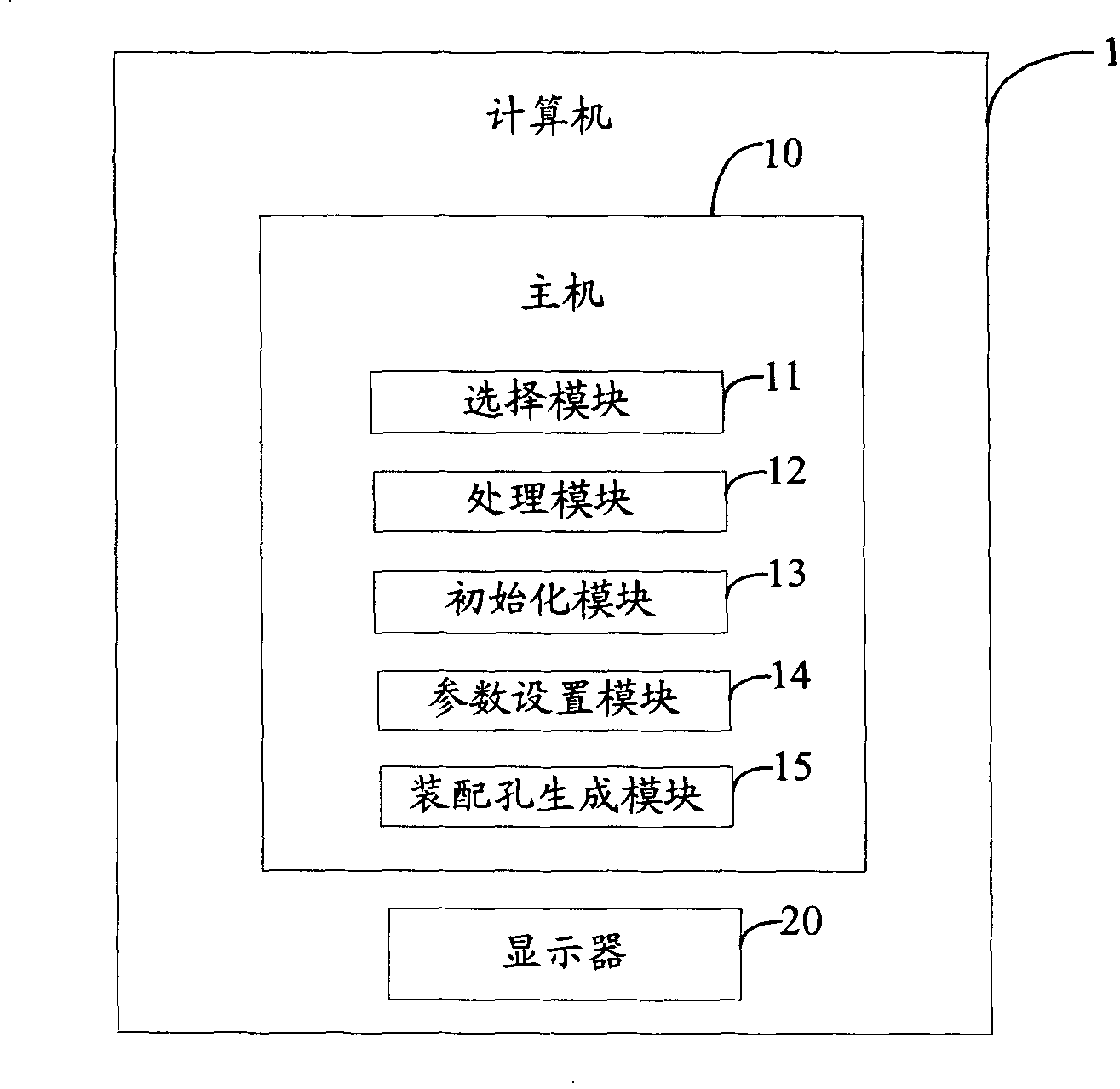

[0015] Referring to FIG. 1 , it is a hardware architecture diagram of a preferred embodiment of the component assembly hole design system of the present invention. The component assembly hole design system includes a computer 1 , and the computer 1 includes a host 10 and a display 20 . Wherein, the host 10 includes a selection module 11 , a processing module 12 , an initialization module 13 , a parameter setting module 14 and an assembly hole generation module 15 .

[0016] Wherein, the selection module 11 is used to select any graphics such as primitives and parts from the design diagram, but when the layer where the graphics is located is locked in the design diagram, the graphics are not selectable. In this preferred embodiment, the design drawing is introduced by taking the mold design drawing as an example. The selection module 11 has two modes for selecting graphics: one is to select the object mode "Object"; mode, it needs to receive the switching command "P" input by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com