Fluorescent x-ray analysis apparatus

An analysis device, X-ray technology, applied in measurement devices, analysis materials, material analysis using wave/particle radiation, etc., can solve problems such as increasing X-ray intensity, limited distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Embodiments of the present invention will be described with reference to the drawings.

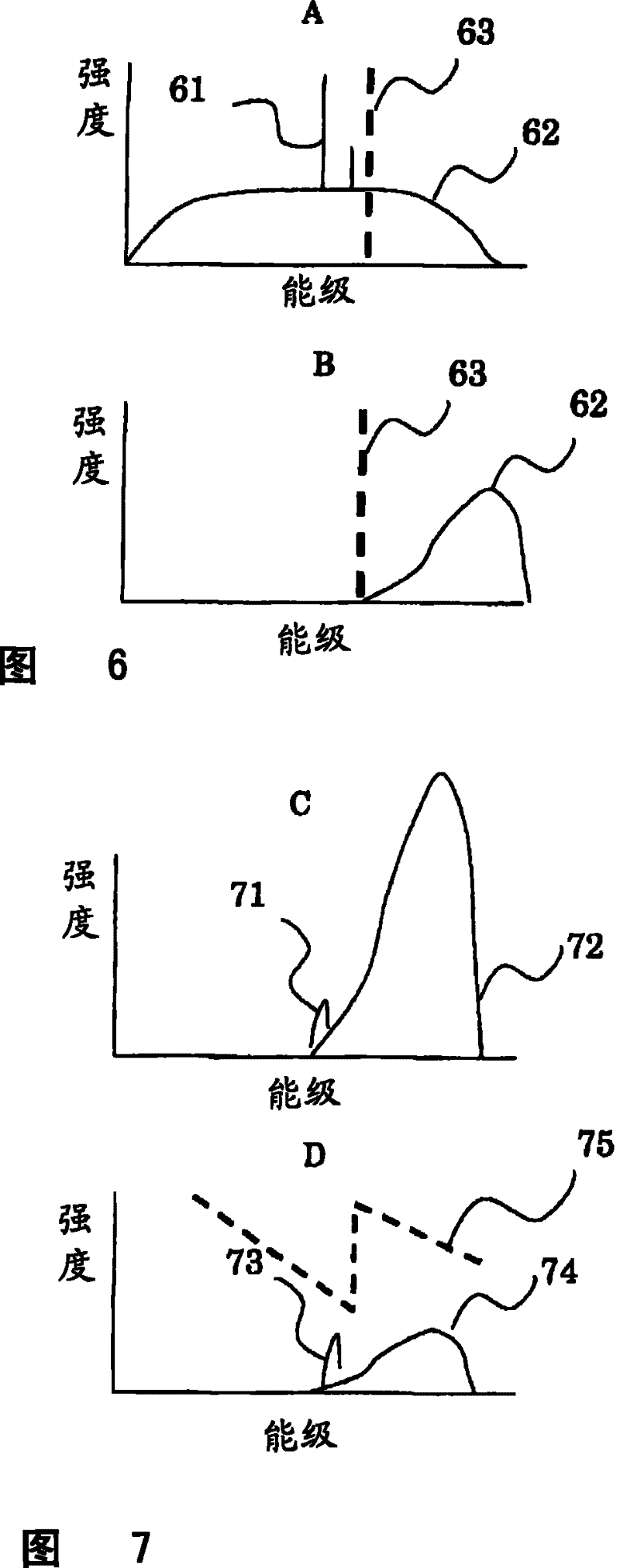

[0066] Figure 8 It is a block diagram of the fluorescent X-ray analysis apparatus of this invention. The X-ray source 1 is controlled by the control unit and the computer unit 82 to irradiate the sample container 8 with primary X-rays, and the X-ray detector 10 acquires secondary X-rays from the sample container 8 . The X-rays incident on the X-ray detector 10 are converted into electrical signals by the amplifier and waveform shaper unit 81 , converted into intensity spectra for each energy level by the control unit and computer unit 82 , and displayed on the monitor 83 . In addition, the control unit and the computer unit 82 also perform density calculation based on the spectral information, and display the information on the monitor 83 .

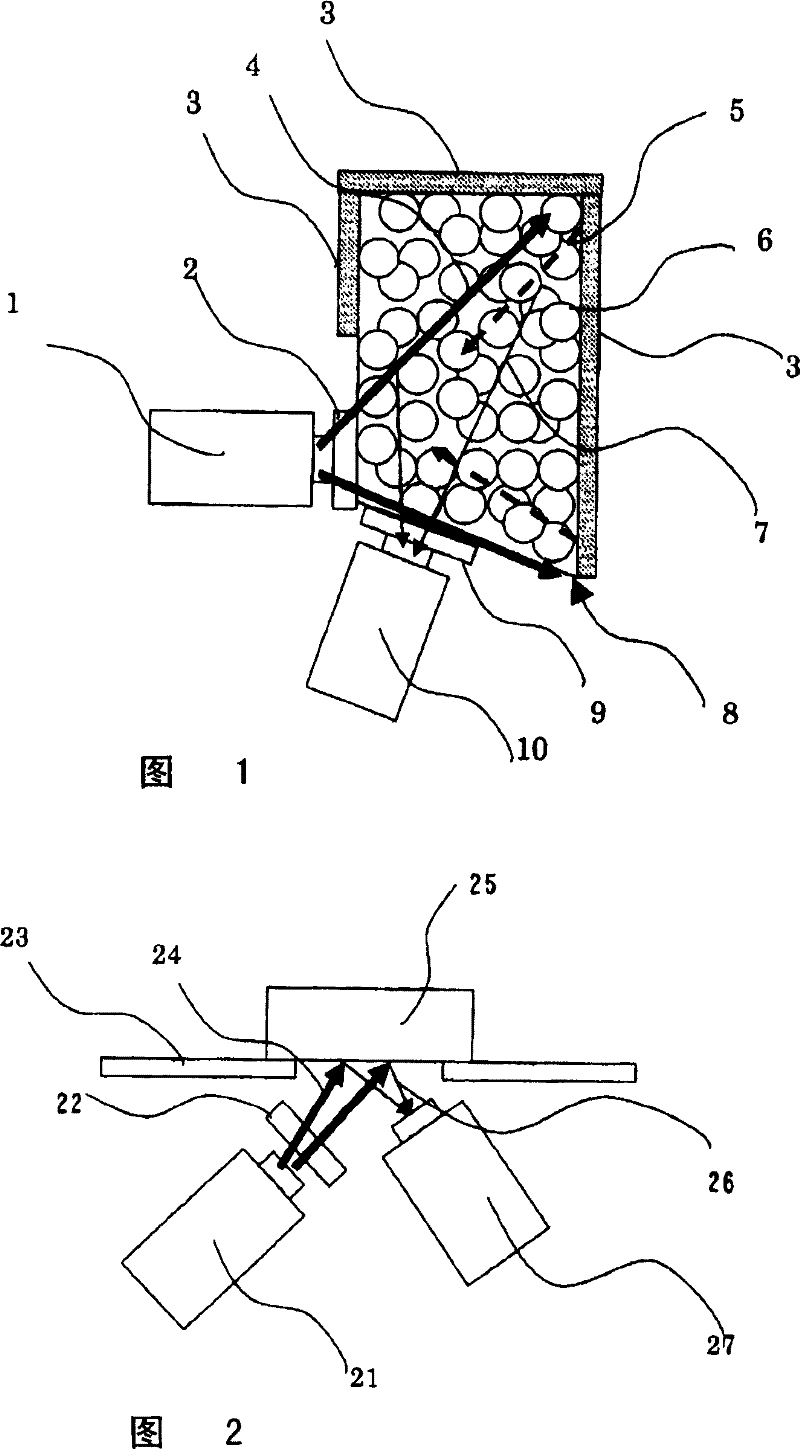

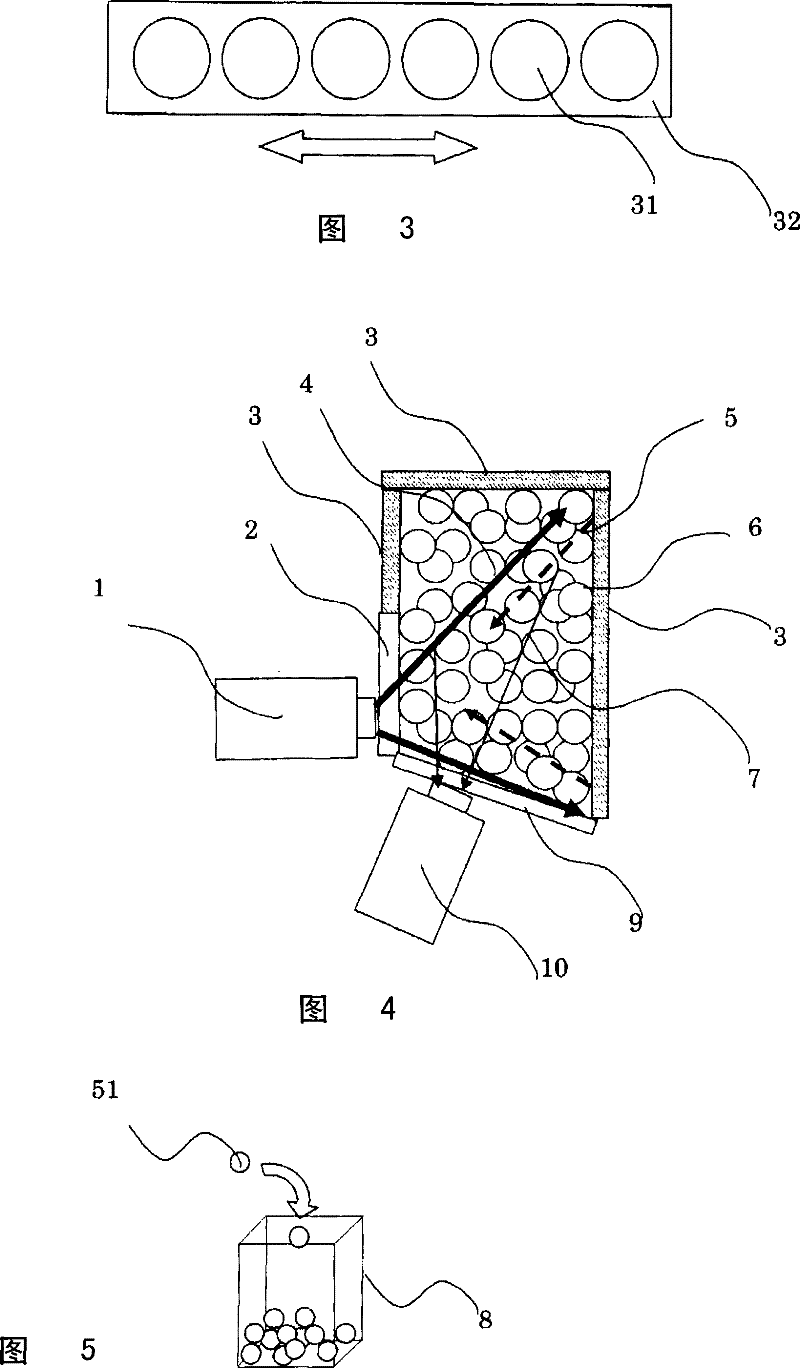

[0067] figure 1 It is a schematic diagram of the X-ray optical system of the fluorescent X-ray analysis apparatus of this invention. exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com