Opening-closing device for plastic drawing-blowing machine pipe taking tongs

A technology of opening and closing device and drawing and blowing machine, applied in the field of plastic machinery, can solve the problems of large occupied space, difficulty in opening and closing of pipe jaws, unfavorable pipe taking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

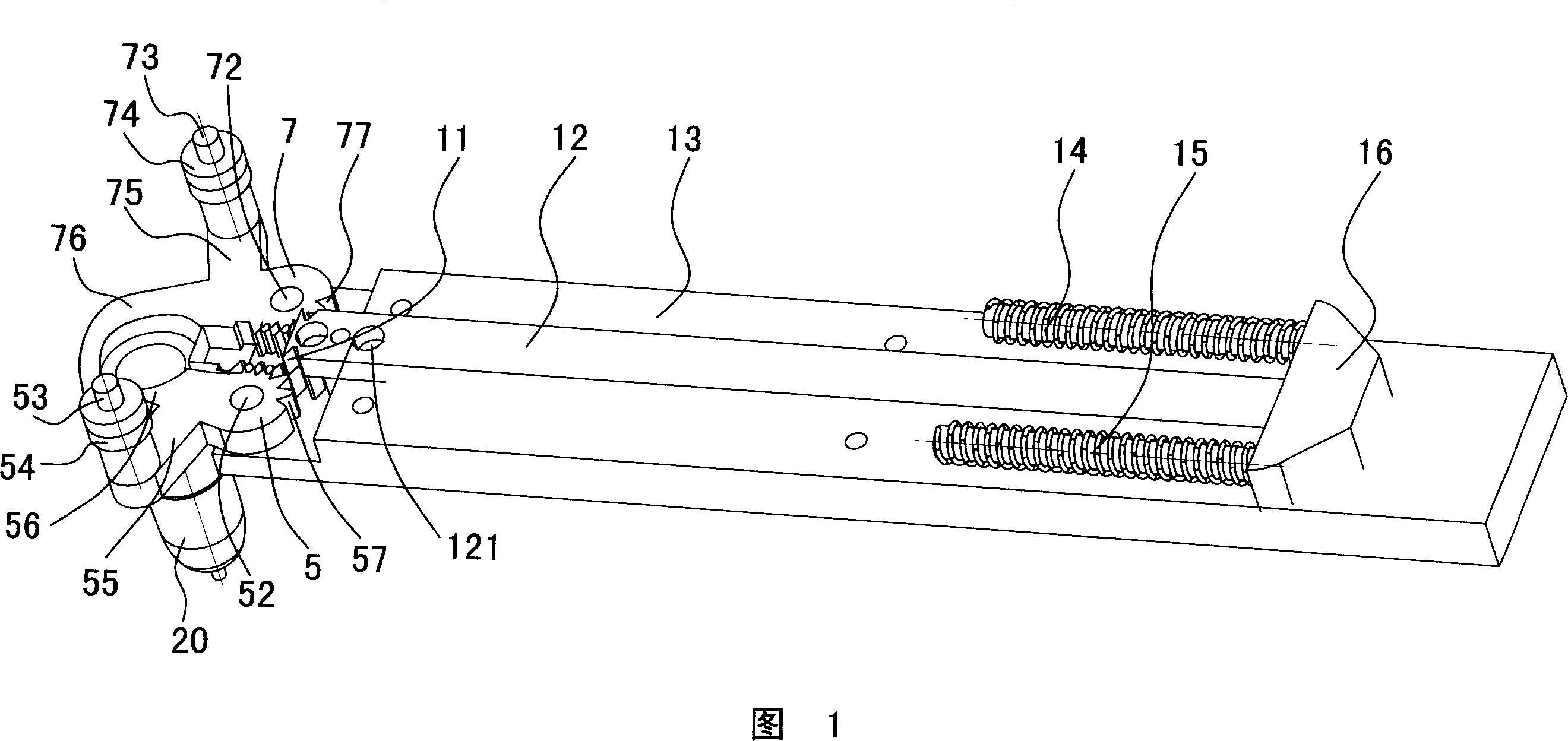

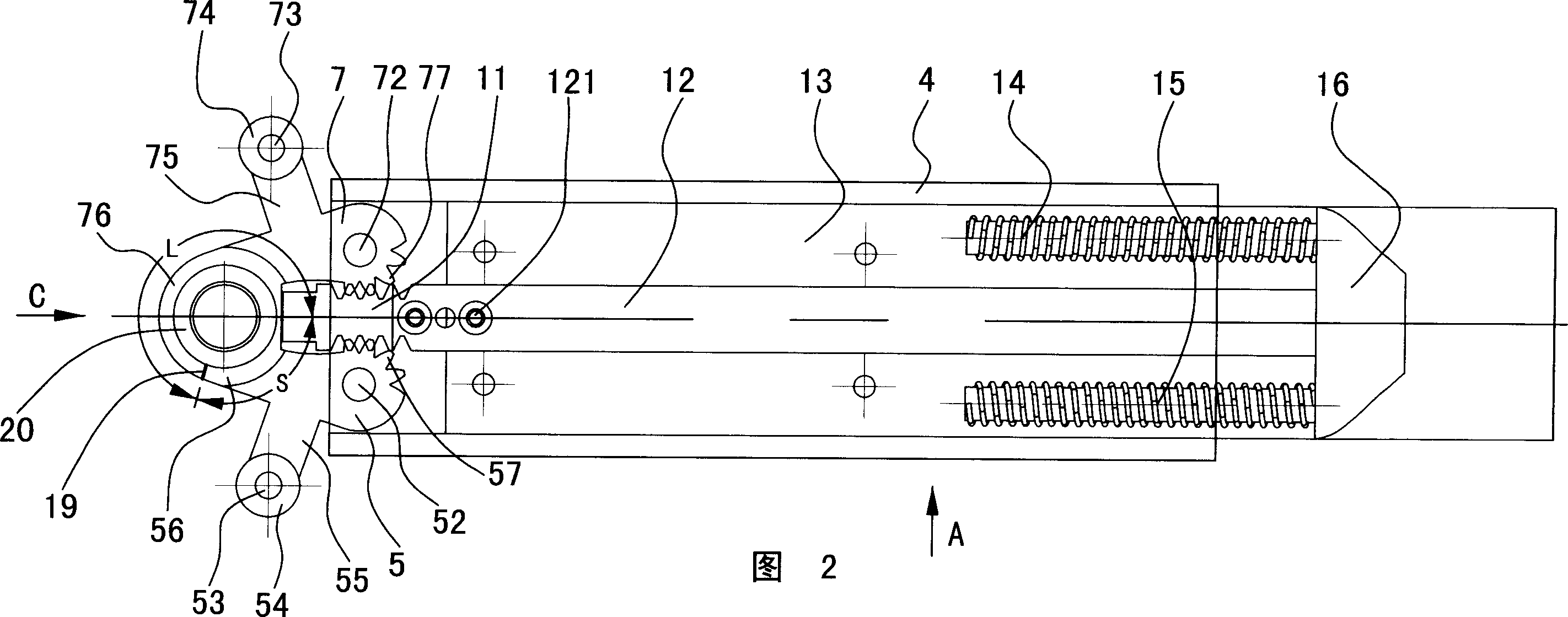

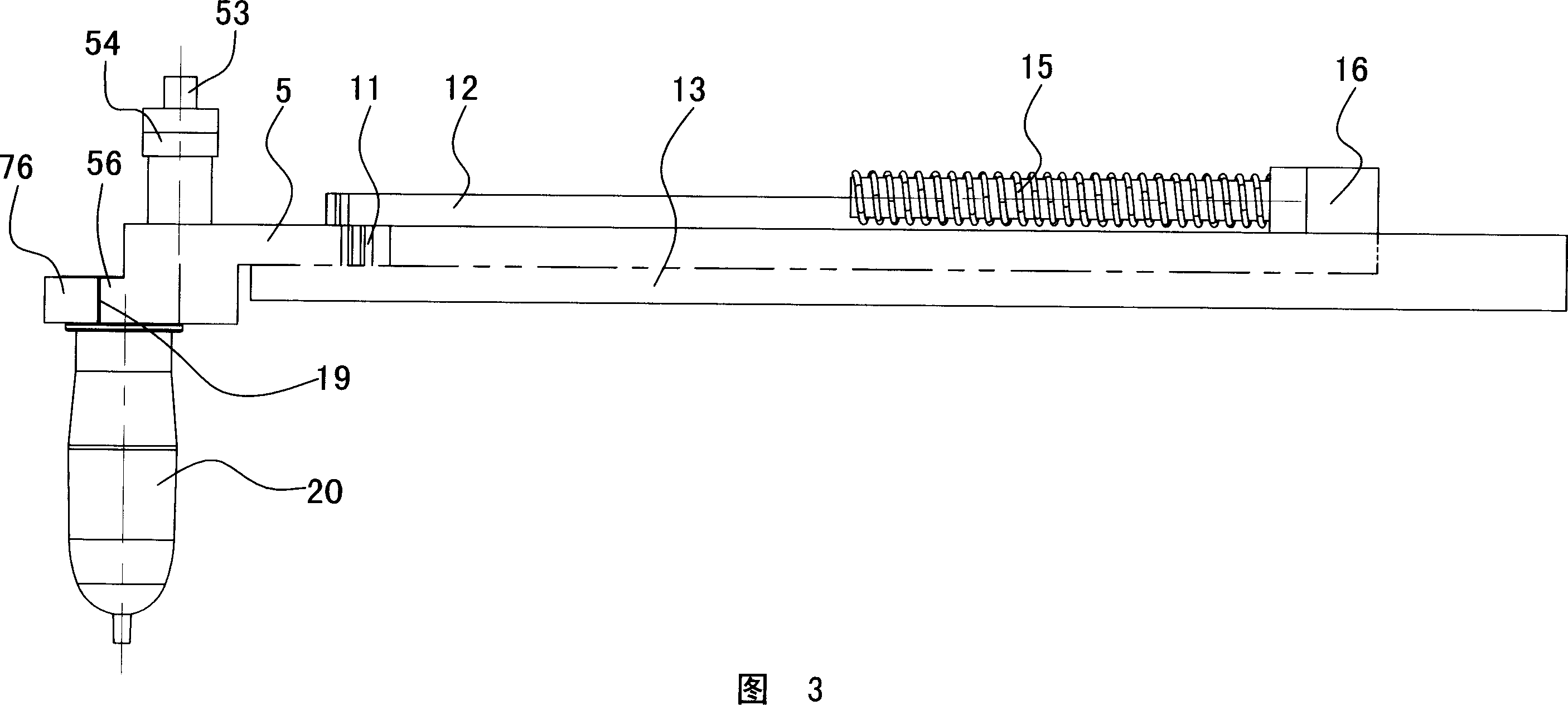

[0011] The present invention relates to the opening and closing device of pipe wrench for plastic stretch blowing machine, as shown in Fig. 1-Fig. There are many specific schemes for the station stretch-blow machine, which belong to the prior art. The stretch-blow machine of each station is equipped with a pipe take-off tong, which is driven by the inner and outer reciprocating motion mechanism, and the inner and outer movement That is, the radial movement from the center to the edge, the reciprocating mechanism makes the pipe tongs take the plastic bottle tube into the mold of the stretch-blow machine, and sends the formed container out of the mold. Its specific structure belongs to the prior art and is not in this case. Get the slide bar 13 heads of pipe wrench and install left and right pincers 5,7, be connected by pin 52,72, left and right pincers 5,7 are respectively shaped on gear teeth 57,77, have on slide bar Push rod 12, the head of push rod connects tooth bar 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com