Electric water heater top layer heating method and quick electric water heater

A technology for electric water heaters and heating methods, applied to water heaters, fluid heaters, lighting and heating equipment, etc., capable of solving problems such as providing sufficient hot water and increasing the volume of storage-type electric water heaters, and achieving small fluctuations in water temperature , reasonable structure and high hot water output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

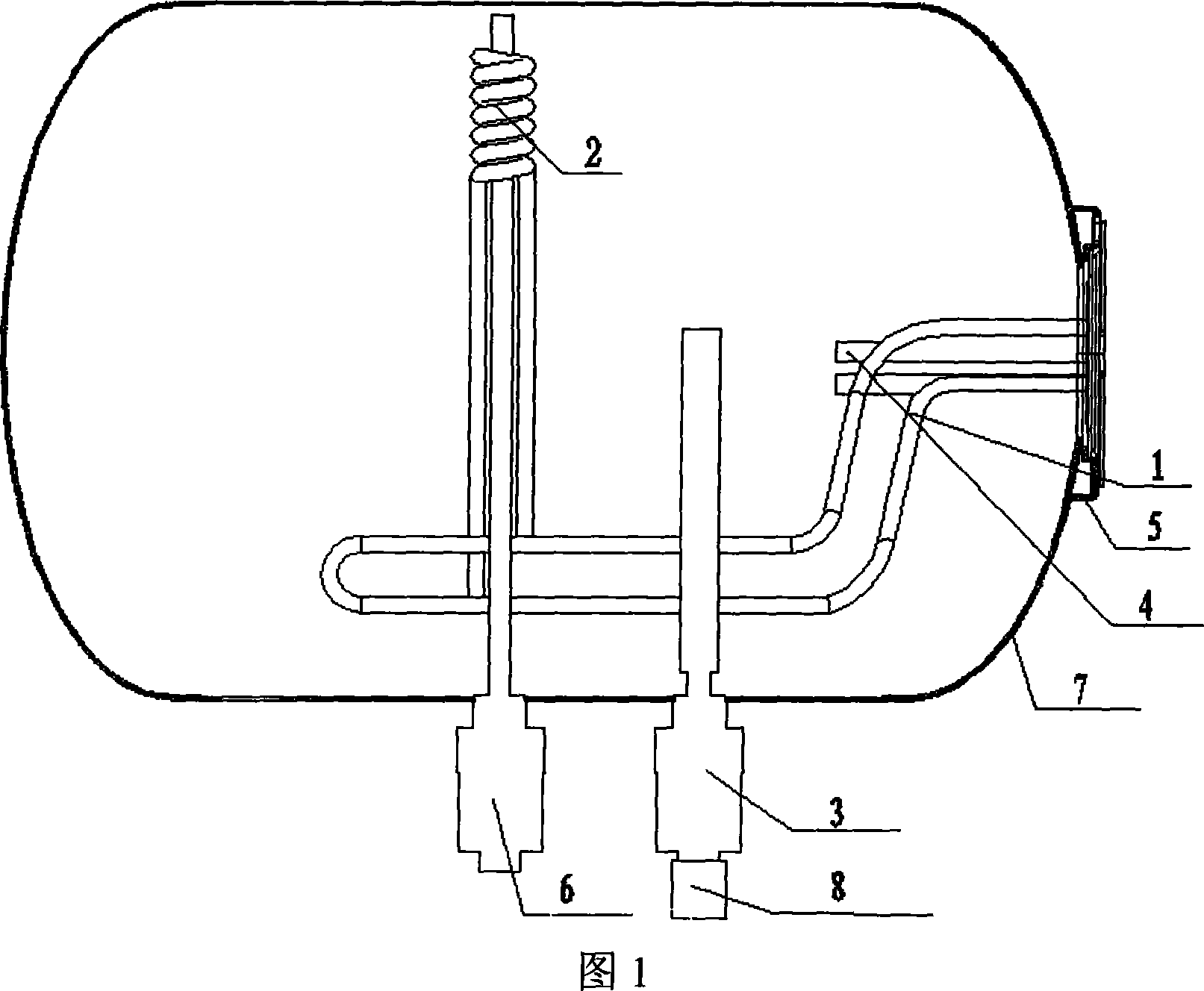

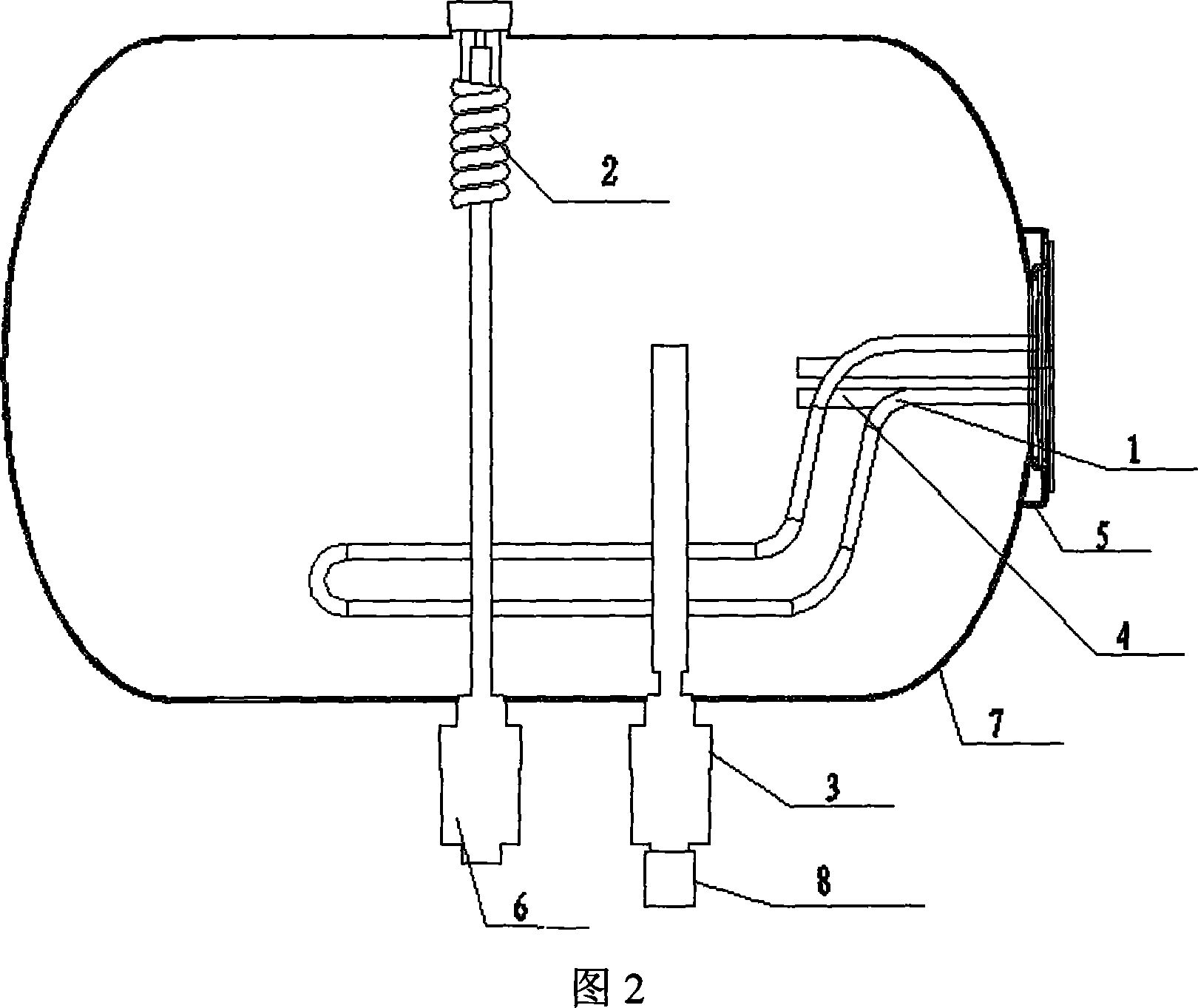

[0017] Embodiment 1: A fast electric water heater, comprising an inner container 7, a water inlet pipe 3, an outlet pipe 6, a main heating pipe 1, a temperature control pipe 4 and a mounting flange 5, and is characterized in that a surrounding The auxiliary heating pipe 2 of the water outlet pipe can reheat the hot water in the inner tank in the heat preservation state.

[0018] The electric heating wire of the auxiliary heating pipe 2 is connected with the water and electricity linkage device to form a power supply control circuit.

[0019] The auxiliary heating pipe 2 is installed on the top of the liner 7 .

[0020] The hydroelectric linkage device is composed of a relay controlled by a sensing element 8 attached to the water inlet pipe 3 or / and the water outlet pipe 6 joint.

Embodiment 2

[0022] The main and auxiliary heating pipes are installed in twins and fixed on one side of the mounting flange 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com