Color laser printing method and its device

A color laser and laser printing technology, which is applied in the fields of optics, electrical recording technology using charge graphics, and electrical recording technology using charge graphics, etc., can solve the problem of color laser printers that cannot be miniaturized in design, complicated assembly process and time, and overall The external structure is bulky and bulky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to achieve the above objects and effects, the technical means and structures adopted in the present invention are described in detail with reference to the accompanying drawings, and the features and functions of the preferred embodiments of the present invention are as follows, so as to facilitate complete understanding.

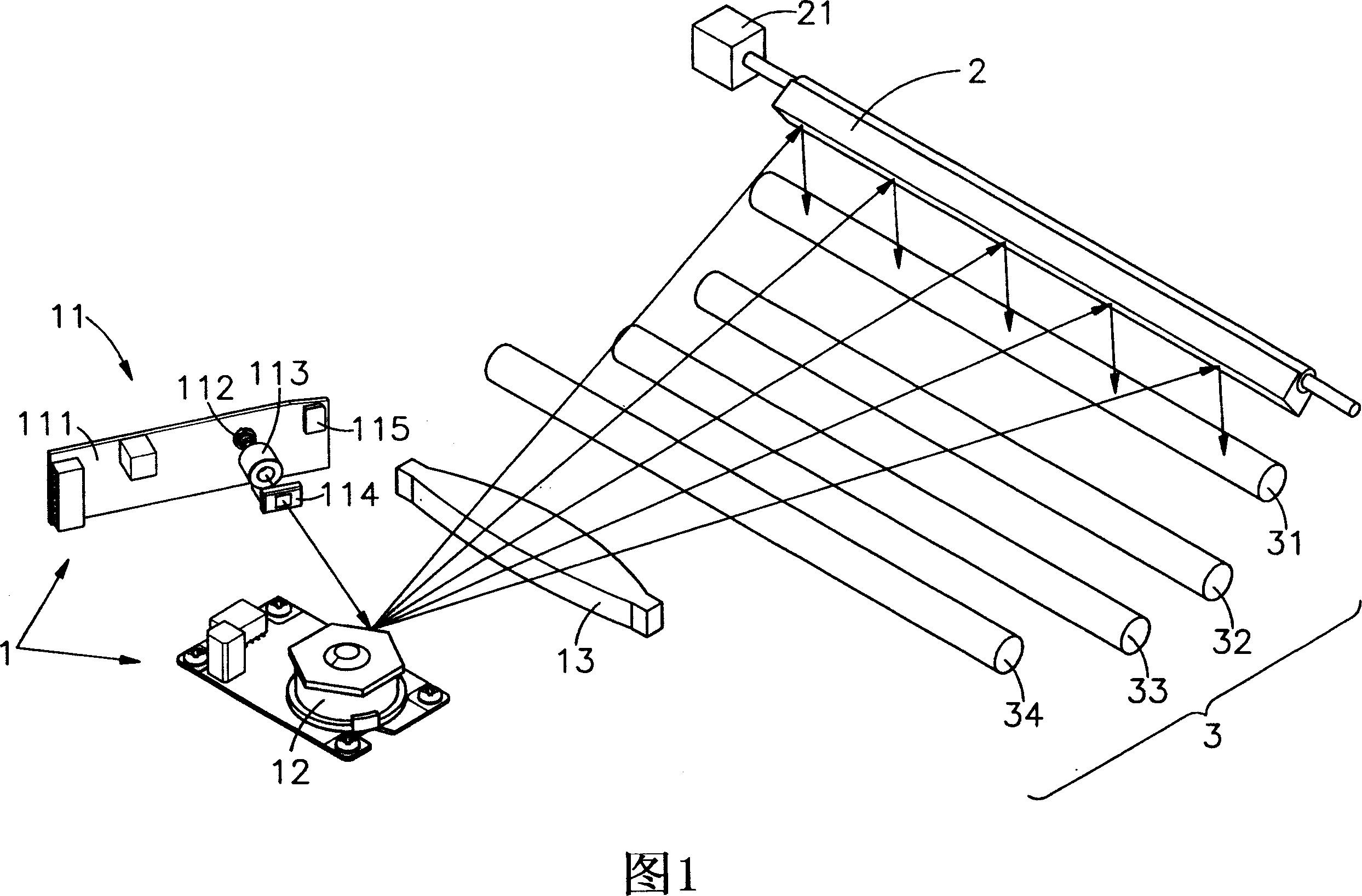

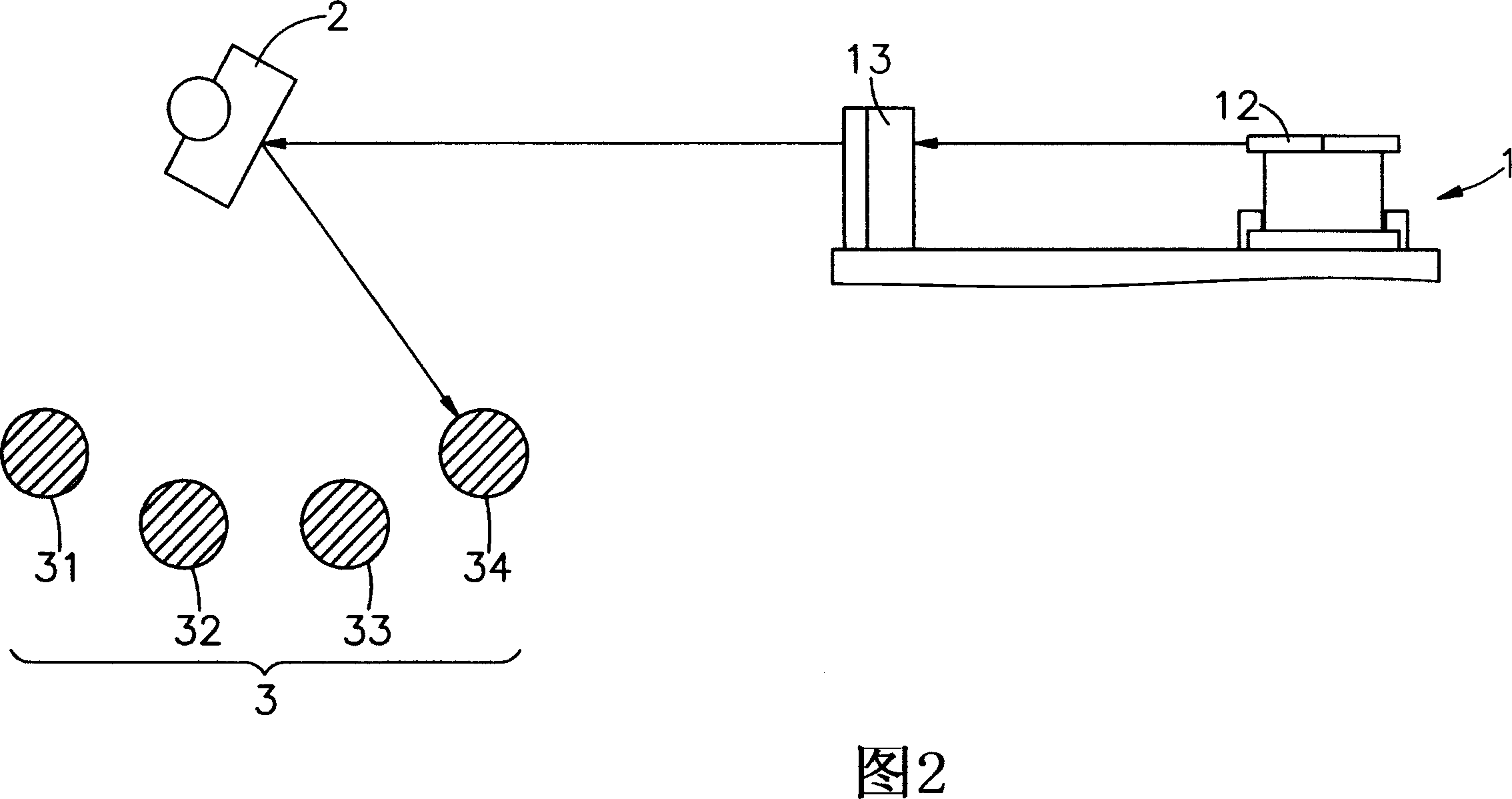

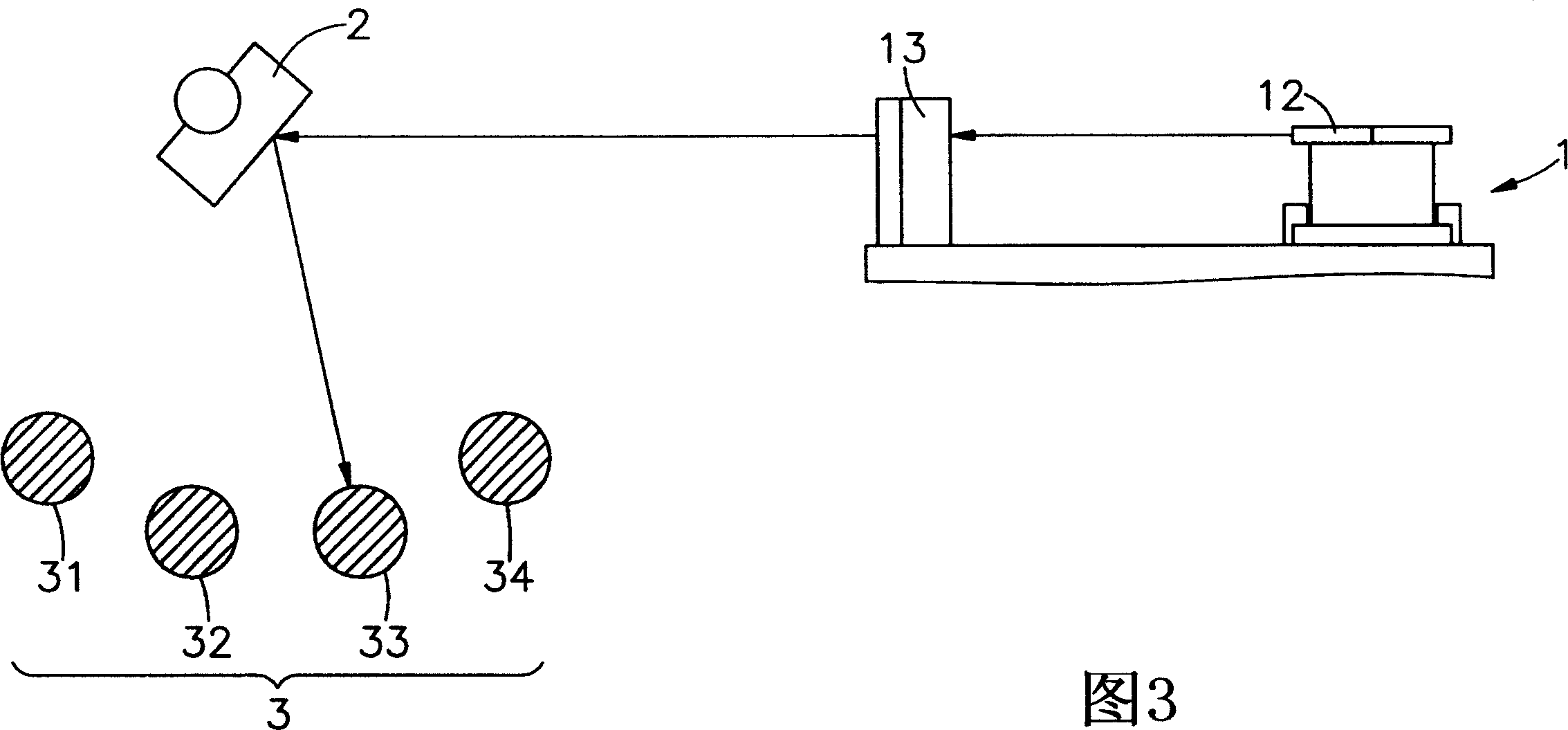

[0027] Please refer to FIGS. 1, 2, 3, 4, and 5 at the same time, which are the three-dimensional appearance diagram, the action diagram (1), the action diagram (2), the action diagram (3) and the action diagram (4) of the preferred embodiment of the present invention. ), it can be clearly seen from the figure that the color laser printing method and device of the present invention are provided with a group of laser scanning units 1 (ie laser scanning unit; LSU) in the laser printer body (not shown in the figure), and The laser scanning unit 1 has a light source device 11, a rotating polygon mirror 12 and a linear scanning mirror 13. The light...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap