Wet type cleaning equipment

A cleaning equipment, wet technology, applied in manual floor scrubbing machinery and other directions, can solve the problems of high manufacturing cost, bulky, large design of sewage tank, etc., and achieve the effect of simplifying assembly steps, reducing manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

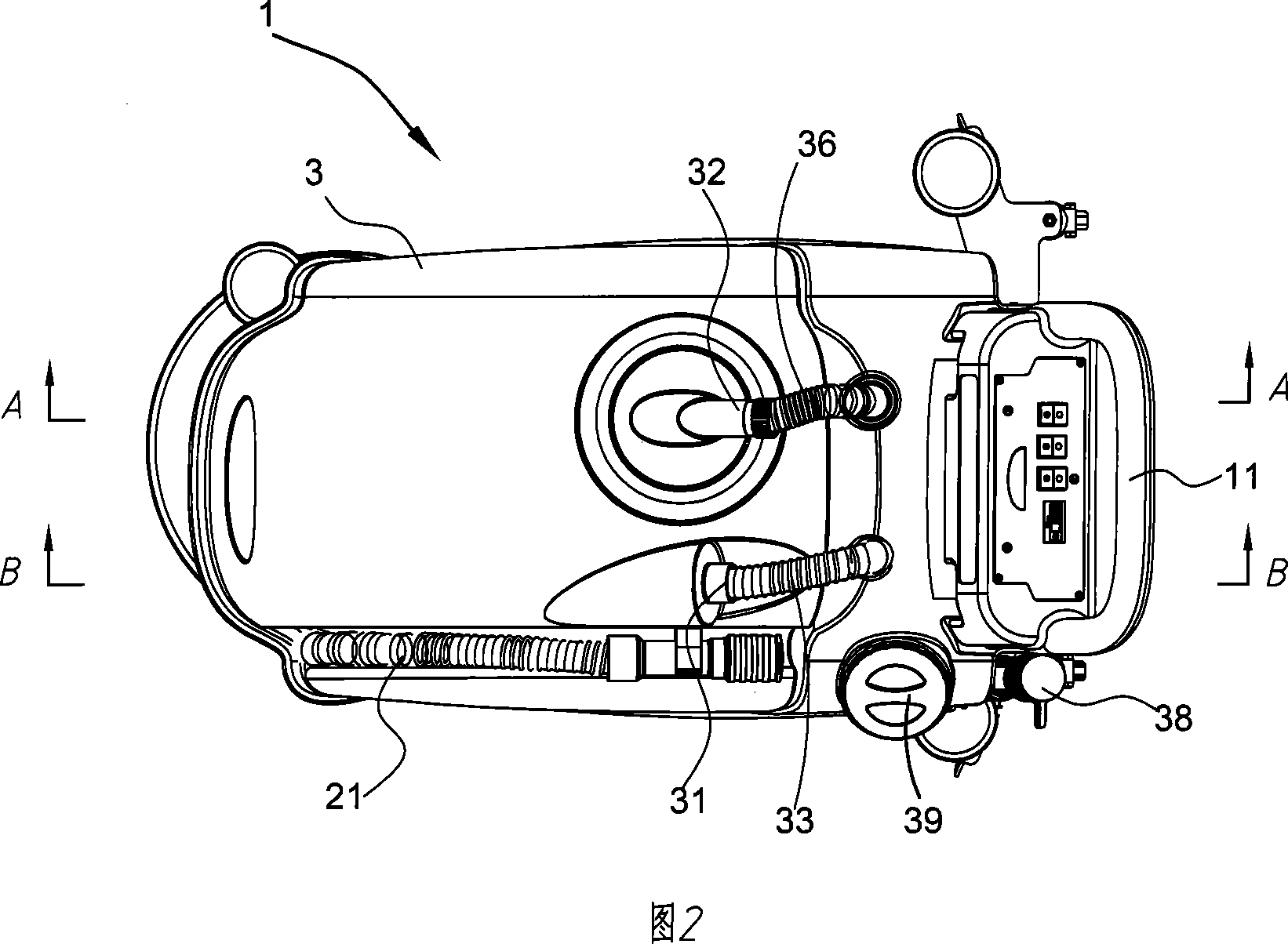

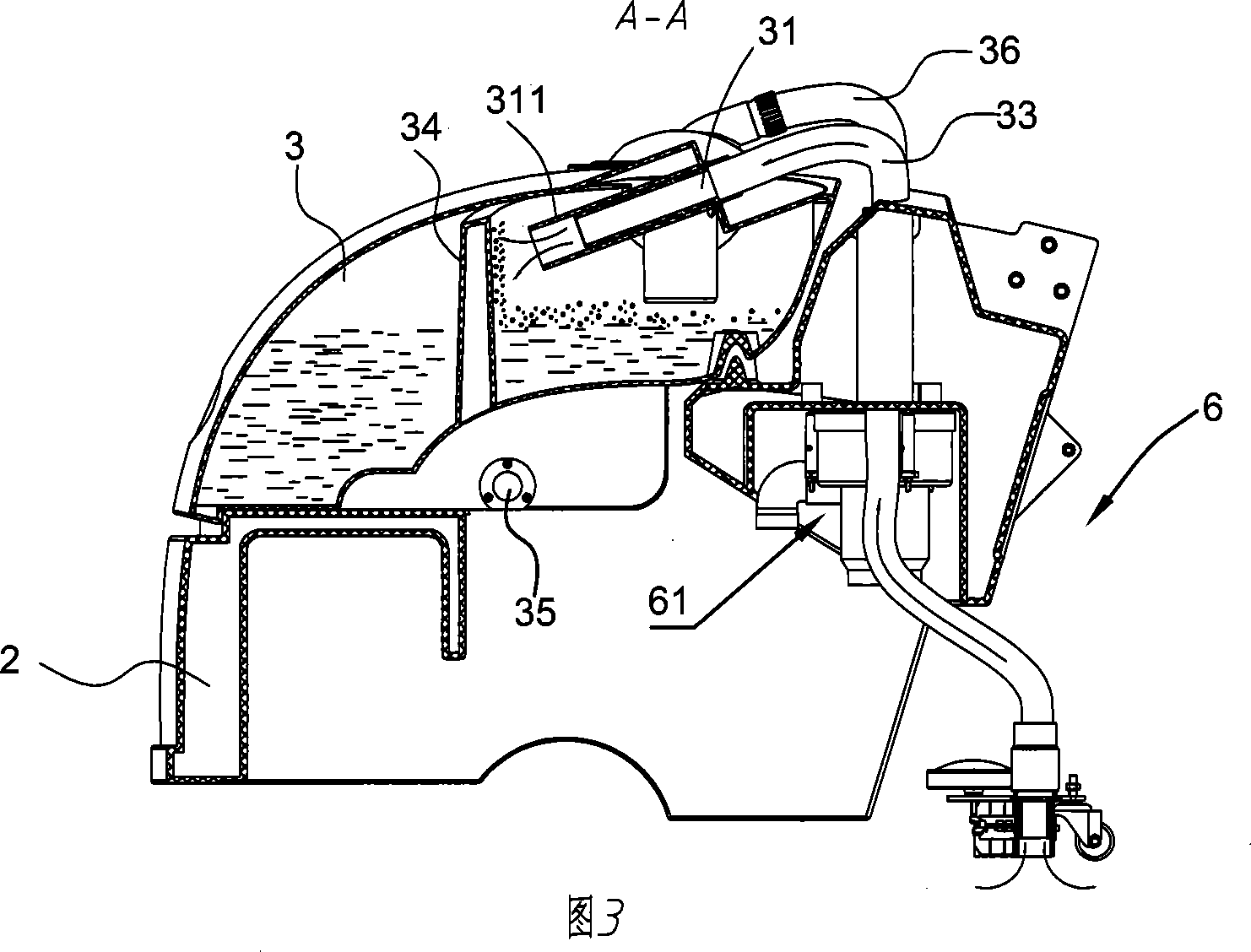

[0028] The present invention will be described in detail below in conjunction with accompanying drawings 1 to 7, but the content of the present invention should not be limited only to the accompanying drawings and the description. Among them, the "front side" described in this specification corresponds to the left side in Figure 2, the "rear side" corresponds to the right side in Figure 2, and the "upper and lower" positional relationship described in the specification Corresponding to the up and down positional relationship shown in accompanying drawing 3.

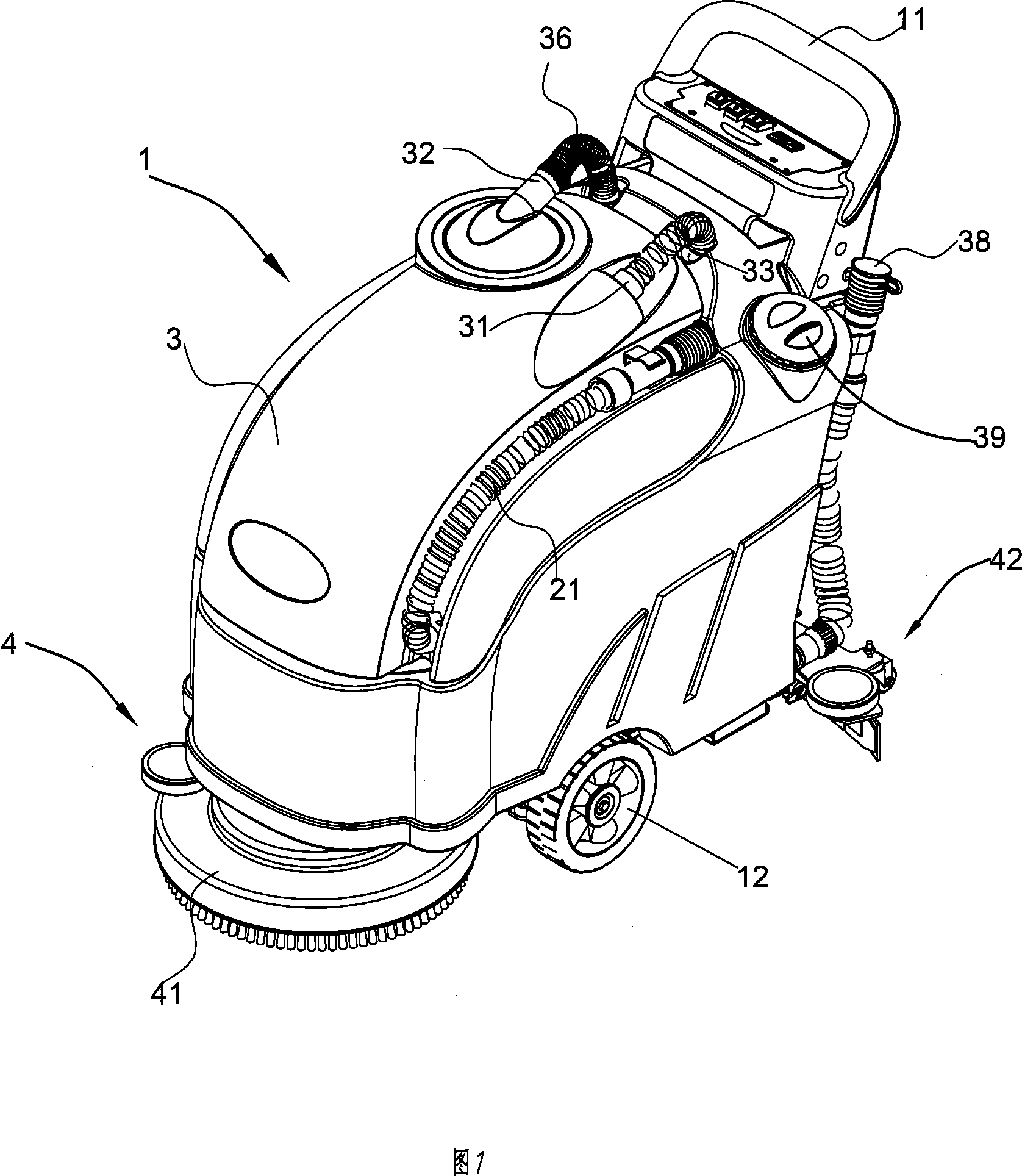

[0029] Accompanying drawing 1 to accompanying drawing 6 disclose a kind of wet cleaning equipment that cleans the floor, and it comprises:

[0030] A base 1 that can move on the ground, the bottom of the base 1 is rotatably provided with rollers 12, and the rear of the base 1 is provided with a handle 11 for holding;

[0031] The cleaning tool 4 located at the bottom of the base 1 and in contact with the ground, the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com