Double face abrading machine

A double-sided grinding machine and end-face technology, which is applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems that the workpiece size cannot meet the precision requirements, low production efficiency, difficult position accuracy, etc. Achieve the effect of high degree of automation, high production efficiency and uniform grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

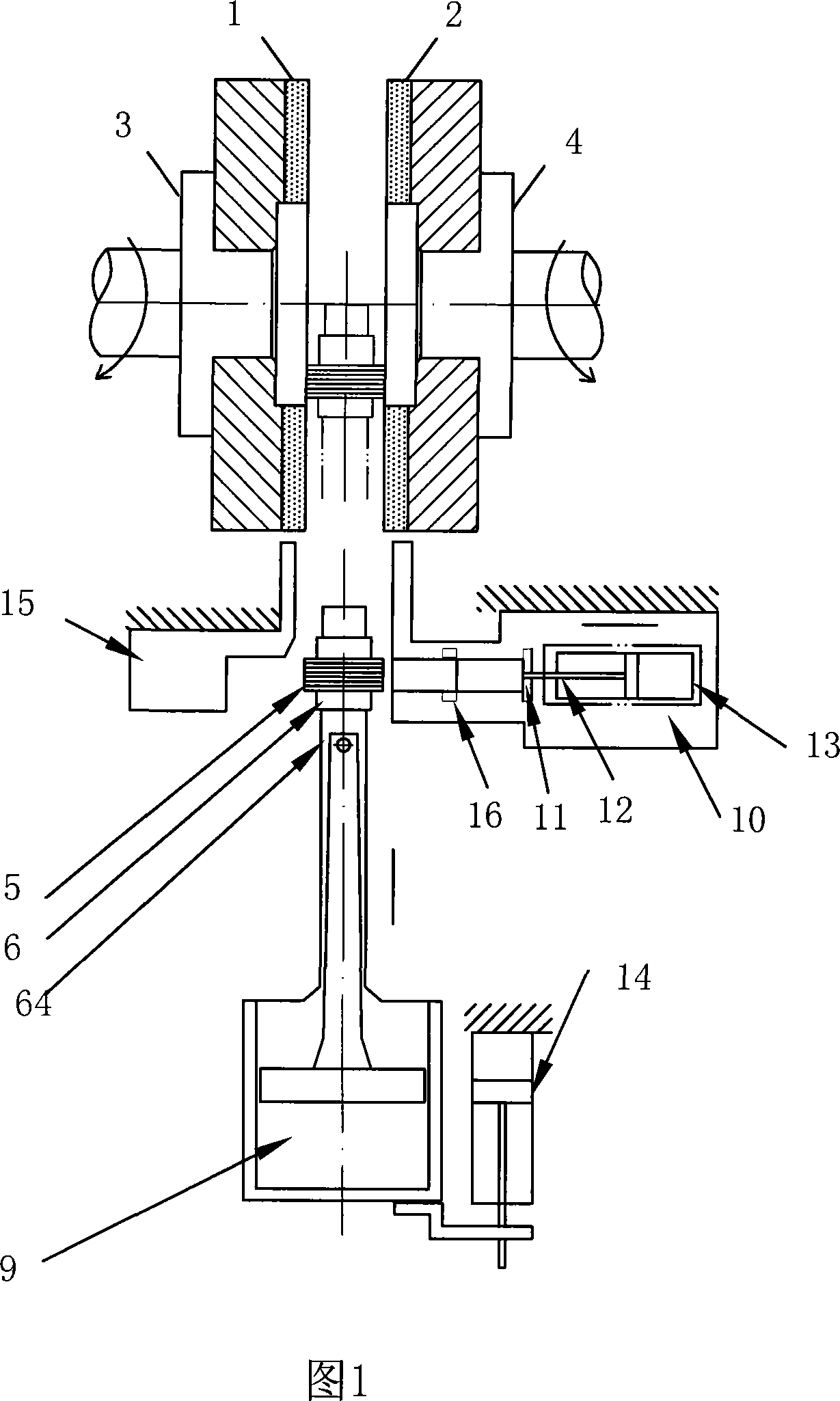

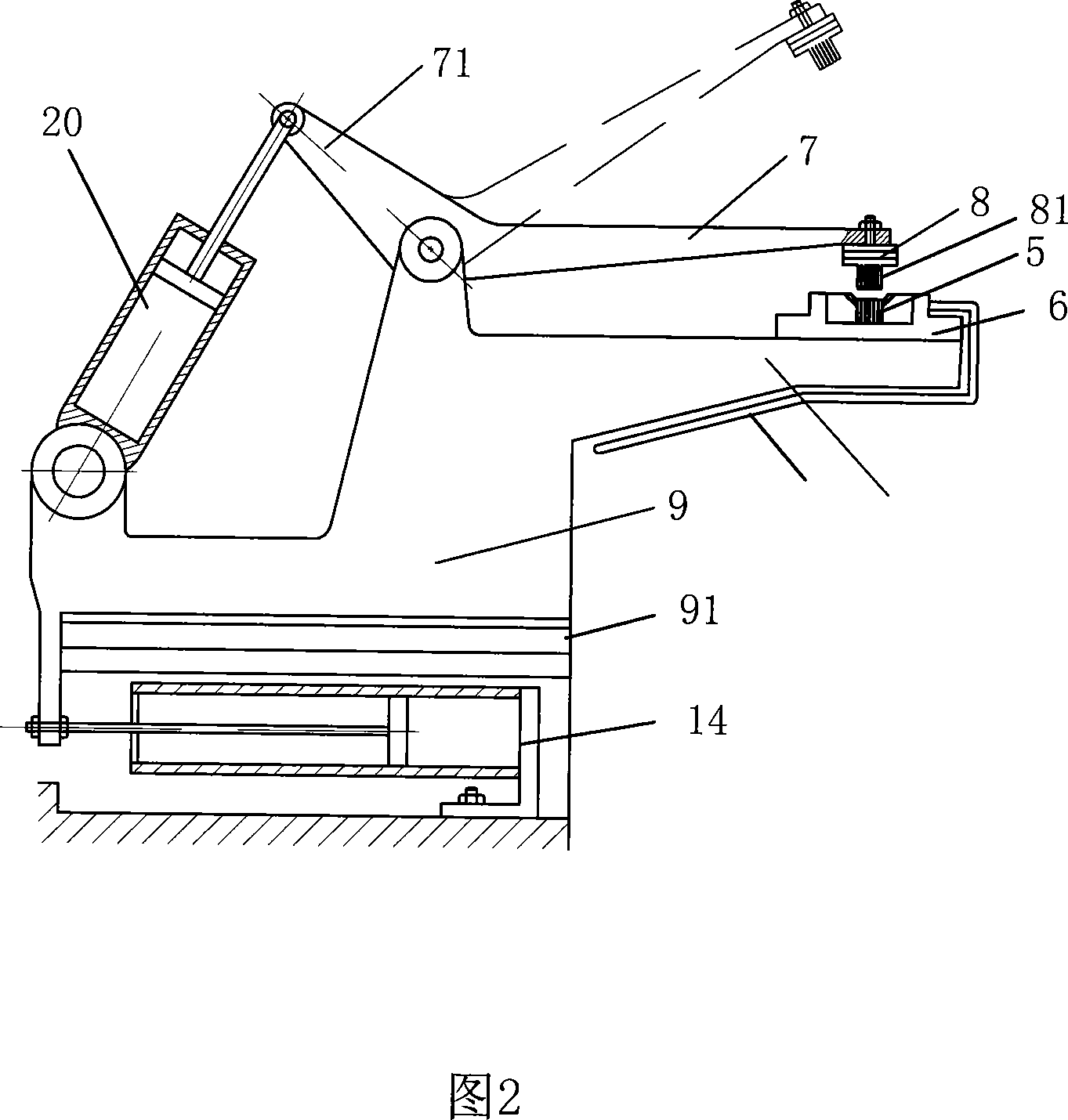

[0026] As shown in Figure 1, the double-sided grinding machine includes a grinding wheel mechanism, a workpiece transfer mechanism, and an automatic feeding mechanism.

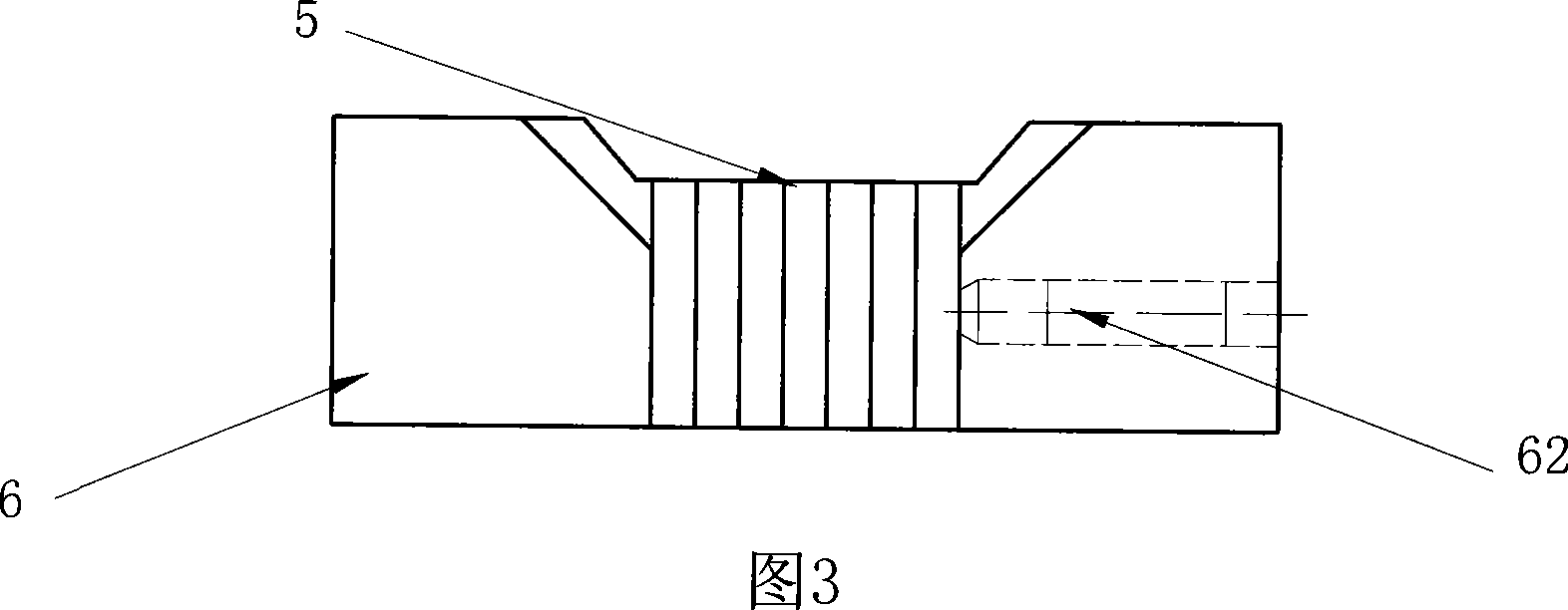

[0027] The grinding wheel mechanism includes main shafts 3 and 4 and grinding wheels 1 and 2 fixed on the main shafts 3 and 4 respectively. The main shafts 3 and 4 are on the same axis line. The grinding wheel 1 and the grinding wheel 2 rotate independently with stepless speed regulation. 4 Independently set the tilt adjustment and axis adjustment mechanism, the adjustment mechanism can adjust the inclination angle of the grinding wheel and the fine and fast feed in the axial direction.

[0028] The two grinding wheels are equipped with a dressing position and a dressing compensation amount. When dressing the grinding wheel, it can quickly enter the dressing position, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap