Heat-insulating housings and preparation method thereof

A technology of a thermal insulation box and a manufacturing method, which are applied in the field of thermal insulation boxes and their manufacturing, can solve the problems of poor outer box, deformation, bad local deformation of rigid polyurethane foam outer box, etc., and achieve the effect of restraining the usage amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

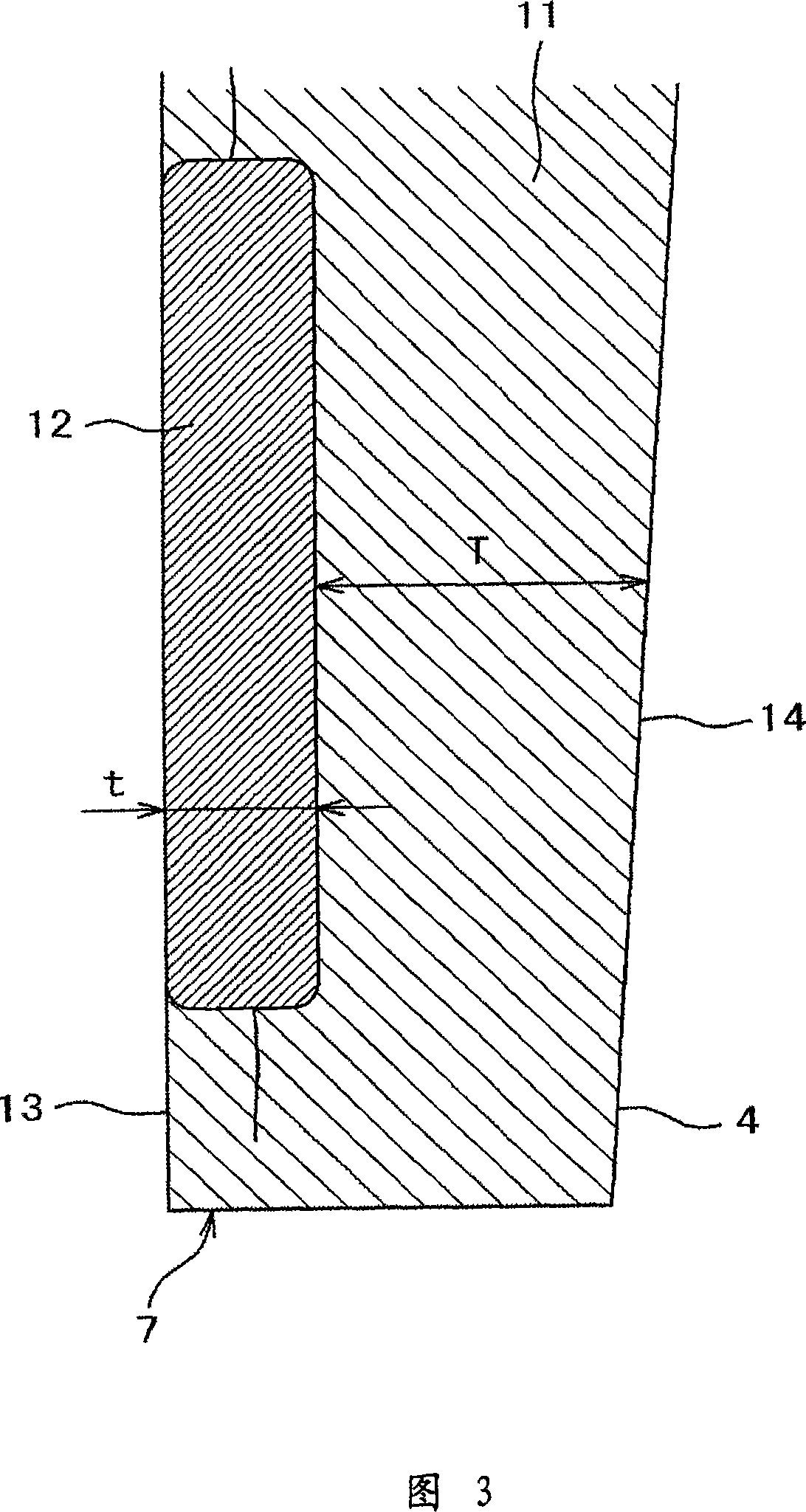

[0044] Example 1 in Table 1 is an example in which the thickness t of the vacuum insulation panel 12 is set to 5 mm, and the flow thickness T of the rigid polyurethane foam 11 is set to 10 mm (T=2t). In this Example 1, when the rigid polyurethane foam 11 is foamed, no unfilled voids are generated near the corresponding portion, and the thermal conductivity is 18.7 mW / m·K, subtracting the central portion from the overall density The numerical value of the density is 3.2, and the rigid polyurethane foam 11 itself is a numerical value not greatly different from that of Conventional Example 1. It is considered that the flow of the rigid polyurethane foam 11 proceeds smoothly, and the material properties inherent in the rigid polyurethane foam 11 are obtained.

Embodiment 2

[0046] Example 2 in Table 1 is an example in which the thickness t of the vacuum insulation panel 12 is set to 5 mm, and the flow thickness T of the rigid polyurethane foam 11 is set to 15 mm (T>2t). In this Example 2, when the rigid polyurethane foam 11 is foamed, no unfilled voids are generated near the corresponding portion, and the thermal conductivity is 18.5 mW / m·K, subtracting the central portion from the overall density The numerical value of the density was 3.4, which was a numerical value not significantly different from Conventional Example 1. This is considered to allow the flow of the rigid polyurethane foam 11 to proceed smoothly, and to obtain the material properties inherent in the actual rigid polyurethane foam 11 .

Embodiment 3

[0050] Example 3 in Table 1 is an example in which the thickness t of the vacuum insulation panel 12 is set to 10 mm, and the flow thickness T of the rigid polyurethane foam 11 is set to 20 mm (T=2t). In this Example 3, when the rigid polyurethane foam 11 is foamed, no unfilled voids are generated near the corresponding portion, and the thermal conductivity is 18.6 mW / m·K, subtracting the central portion from the overall density The numerical value of the density is 3.5, and the rigid polyurethane foam 11 itself is a numerical value not significantly different from that of Conventional Example 1. It is considered that the flow of the rigid polyurethane foam 11 proceeds smoothly, and the material properties inherent in the rigid polyurethane foam 11 are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com