Surface treating method of copper or copper ally

A technology of surface treatment and surface treatment agent, applied in the field of surface treatment of copper or copper alloys, can solve the problems of poor replacement of air and surface treatment agent, difficulty, difficulty in forming an anti-rust film on copper pads, etc. The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

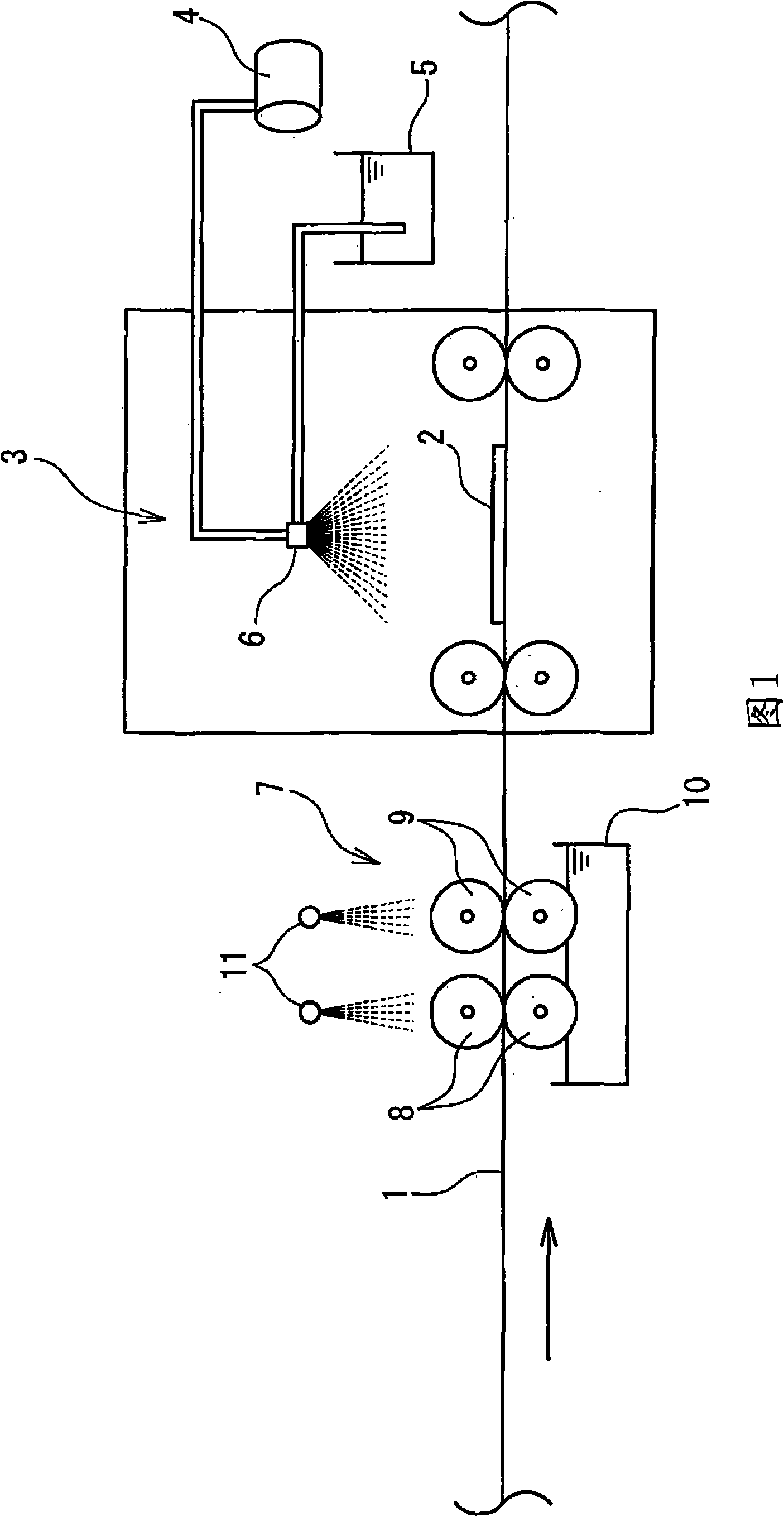

Method used

Image

Examples

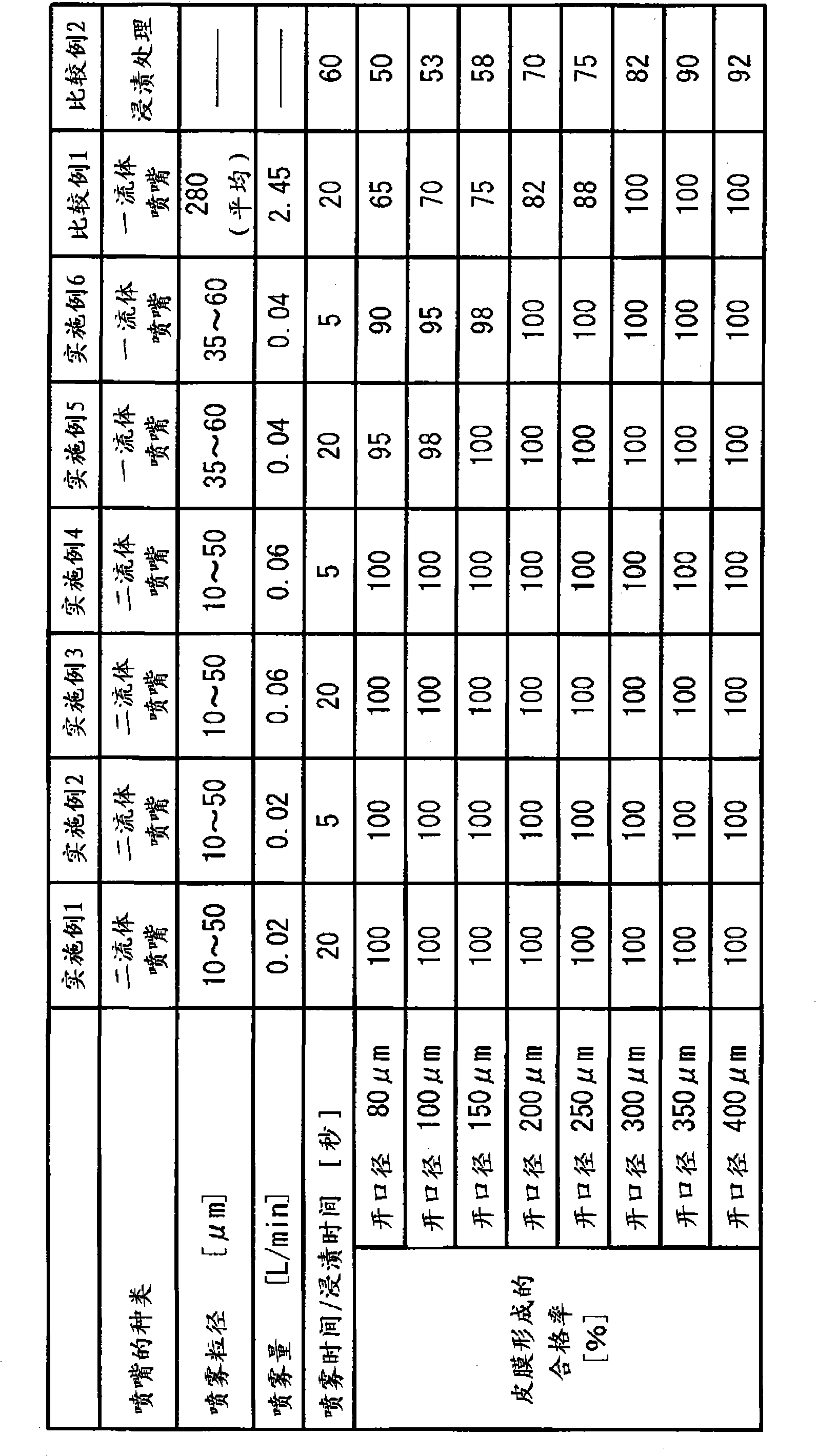

Embodiment 1

[0037]Example 1 uses a two-fluid spray treater. The two-fluid spray treatment machine includes an air compressor part, a copper surface treatment agent storage part and a spray treatment part, and each part is connected by piping. According to the principle of mist blowing, the copper surface treatment agent is sucked from the copper surface treatment agent storage part by the compressed air from the air compressor part, and the air and the copper surface treatment agent are mixed and sprayed in the two-fluid nozzle.

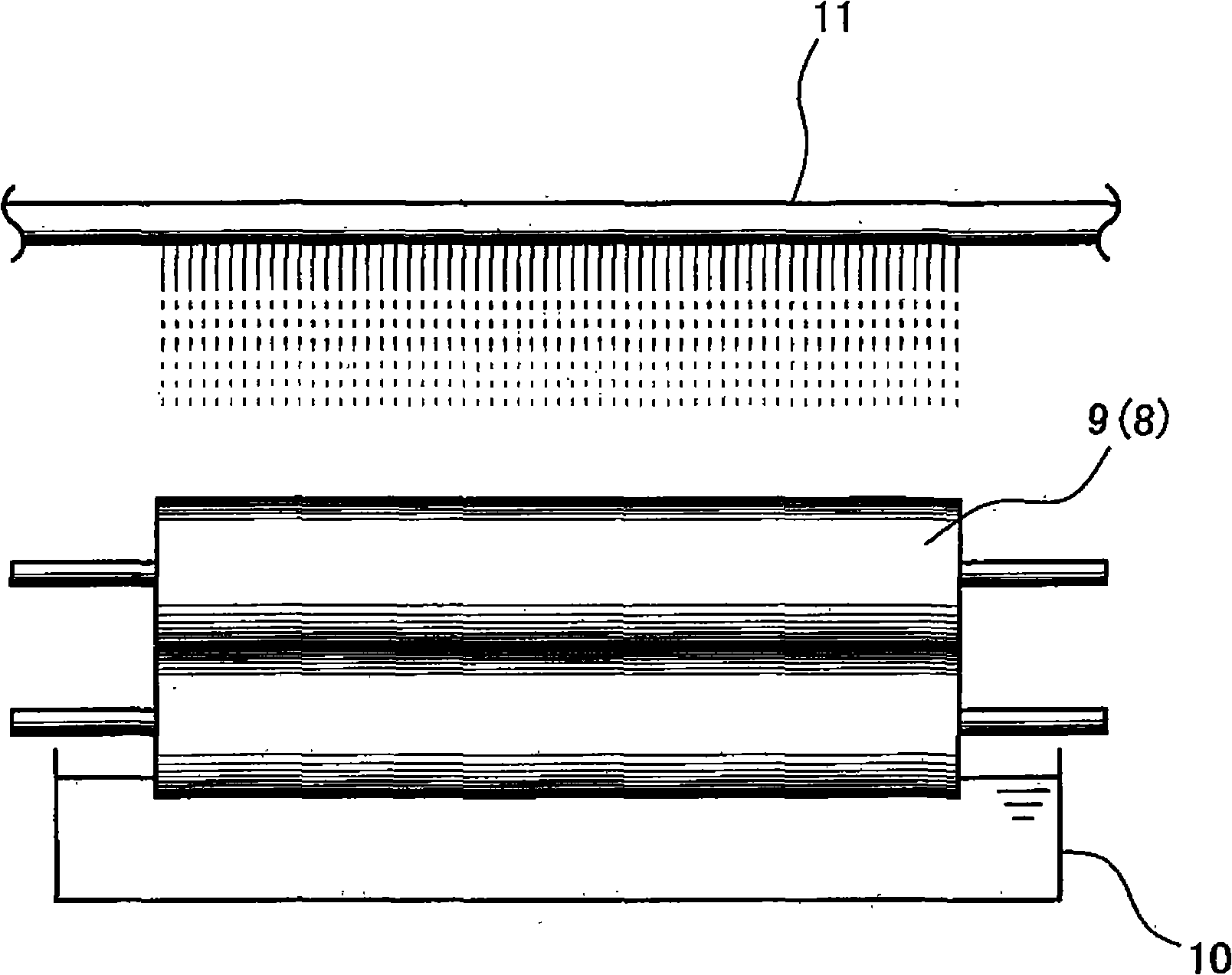

[0038] When the substrate is conveyed by the conveying device, nozzles are provided above and below the conveying surface in order to simultaneously process the upper surface and the lower surface of the substrate. The position of the nozzle was set at a position 10 cm away from the conveyance surface. As the two-fluid nozzle, BIMV8002S (trade name, two-fluid nozzle manufactured by Ikeuchi Co., Ltd.) was used.

[0039] As a surface treatment agent, MECSEAL CL-...

Embodiment 2

[0041] Example 2 was processed in the same manner as in Example 1 except that the spraying time was set to 5 seconds.

Embodiment 3

[0043] In Example 3, in the same spray processor as in Example 1, BIMV8075S (trade name, two-fluid nozzle manufactured by Ikeuchi Co., Ltd.) having a different flow rate was used. As a surface treatment agent, the same MECSEAL CL-5018S as in Example 1 was used. The spray time was set to 20 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com