Illuminator and method for producing such illuminator

A light emitter and light source technology, applied in the field of light emitters, to achieve the effect of maximizing optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

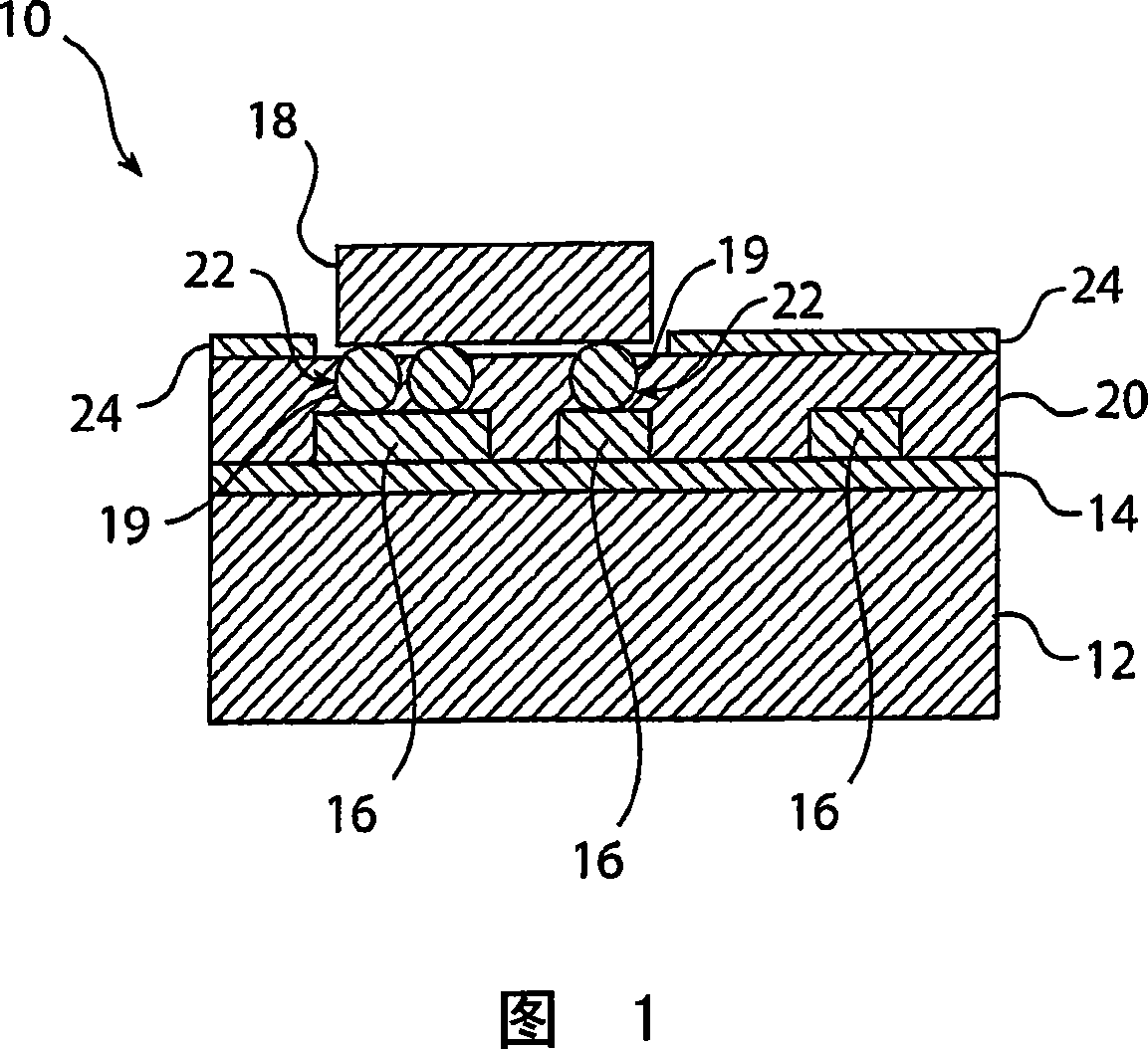

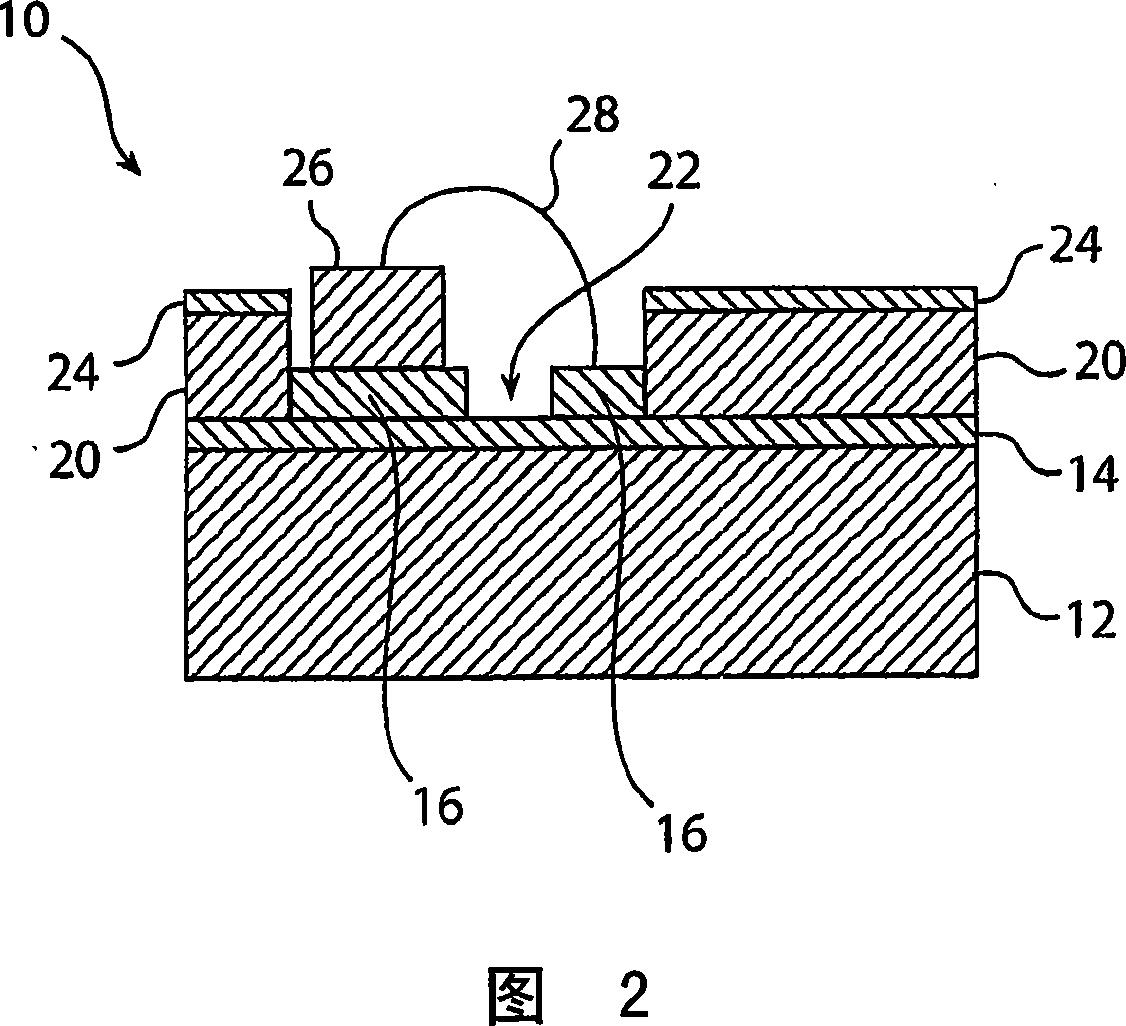

[0020] 1 shows a light emitter 10 according to an embodiment of the present invention. The light emitter 10 includes a substrate 12, such as a silicon substrate, a dielectric layer 14 formed on the substrate 12, and a structure formed on the dielectric layer 14. conductive layer 16. The structured conductive layer 16 covers part of the substrate surface and forms conductive tracks on which the LED chips 18 with contact pads 19 are mounted. Thus, through the structured conductive layer 16, the LED chip 18 can be electrically connected to an external circuit. The LED chip 18 in FIG. 1 is flip-chip mounted, and the conductive layer 16 preferably comprises Cu.

[0021] The substrate with the LED chips 18 is preferably covered by optical elements (not shown), such as optical lenses or collimators. Likewise, the bottom side of substrate 12 is preferably soldered to a heat sink (not shown) for heat dissipation.

[0022] According to the invention, an insulating layer (20) is furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com