Roll washing machine mounted washing agent throw-in arrangement

A technology of drum washing machine and detergent, which is applied in the field of washing machines and can solve the problem that the detergent box does not have quantitative indication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

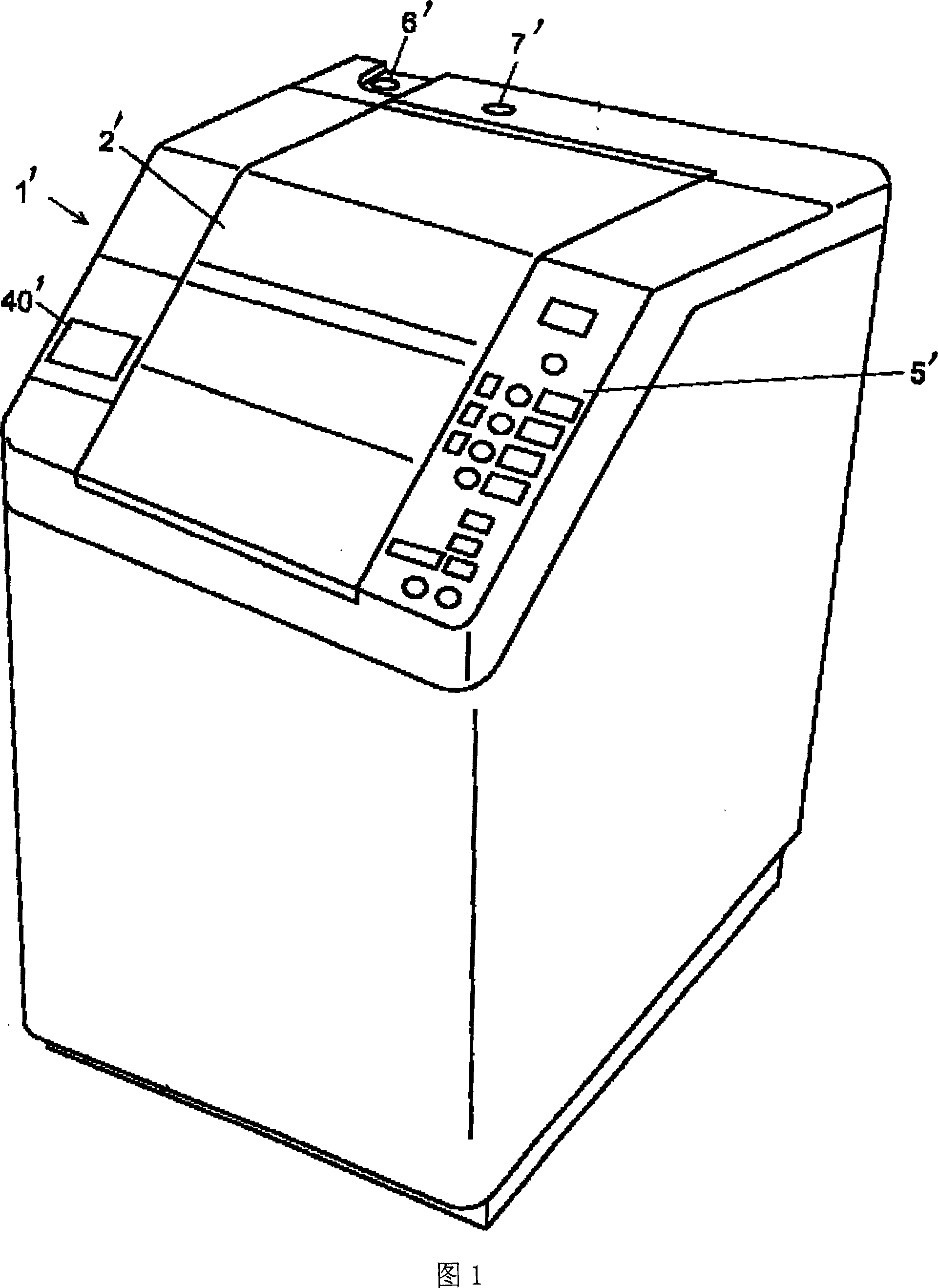

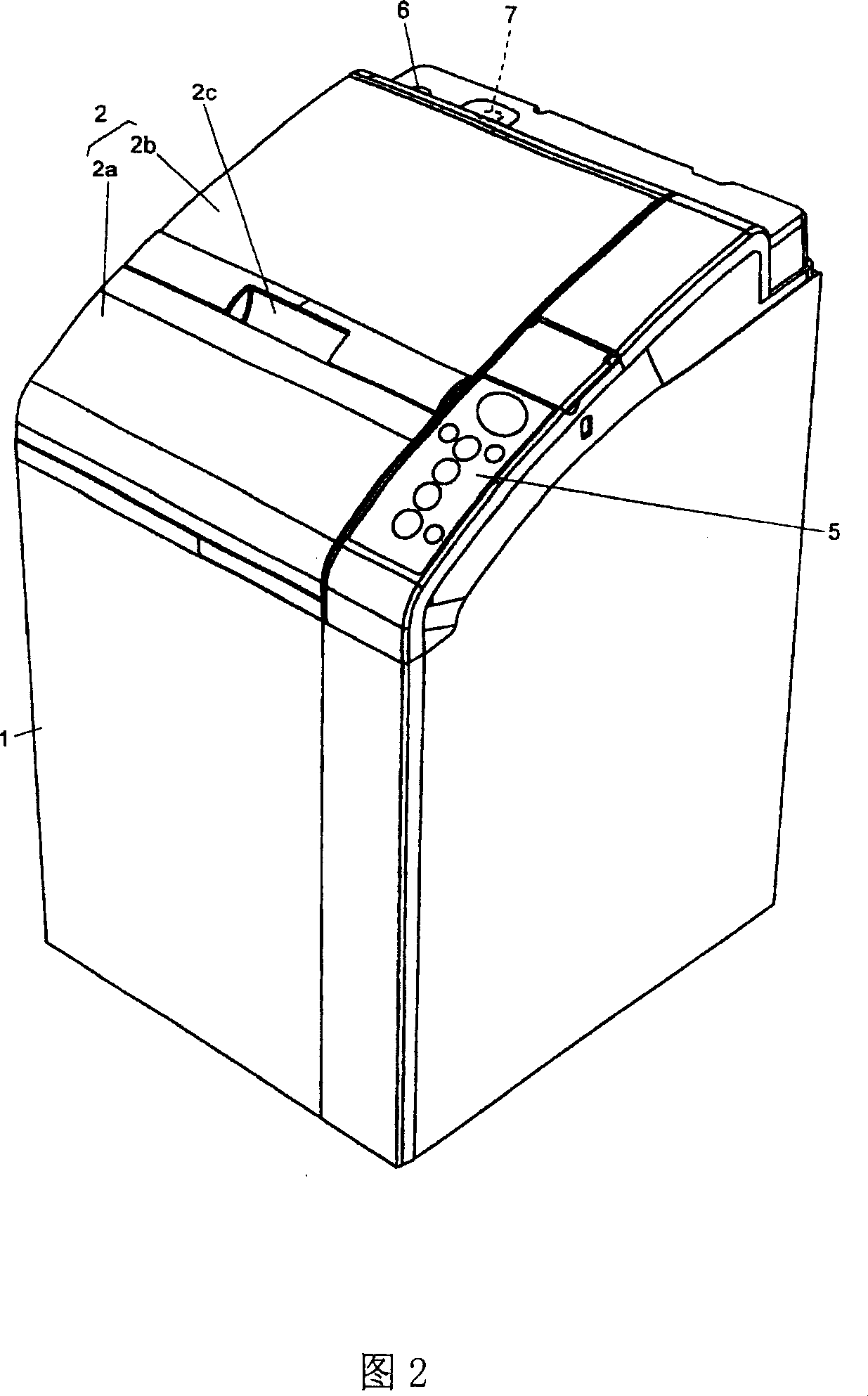

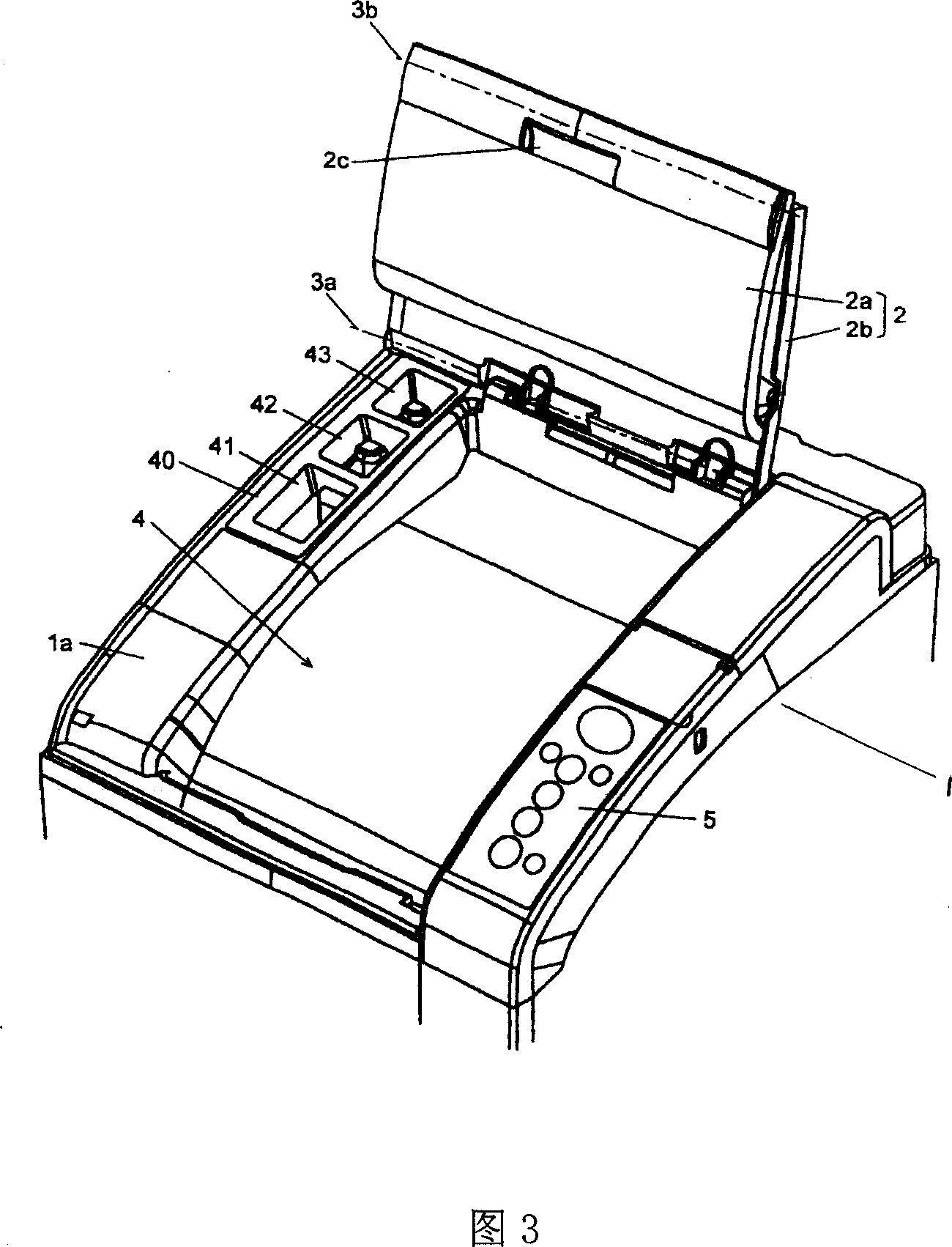

[0029] Fig. 4 is a perspective view of the appearance of a drum washing machine provided with a detergent input device provided by the present invention. Agent input device 110. In the illustrated embodiment, in the drum washing machine, the top panel 101 of the shell 100 is arc-shaped, and at the same time slopes forward and downward, and a large laundry inlet 104 is formed on the top surface along the front-back direction. The top cover that is used to realize the opening and closing of the laundry inlet 104 is a soft curtain door 102 that pushes and pulls back and forth. The two sides of the soft curtain door 102 are slidably arranged in the chute 103 on both sides of the input port 104, the user grasps the handle 105 arranged on the front end of the soft curtain door, pushes forward and upward, and the input port can be opened. 104 is opened (the soft curtain door shown in Figure 4 is in a half-open state), and then the soft curtain door 102 that is arranged on the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com