Plastic radicel denseness Composite floor

A composite floor and density board technology, applied in the field of plastic-based density composite floor, can solve the problems of lack of solid wood floor effect, poor assembly accuracy, low strength, etc., to achieve good stability and noise reduction effect, convenient laying, strong variability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

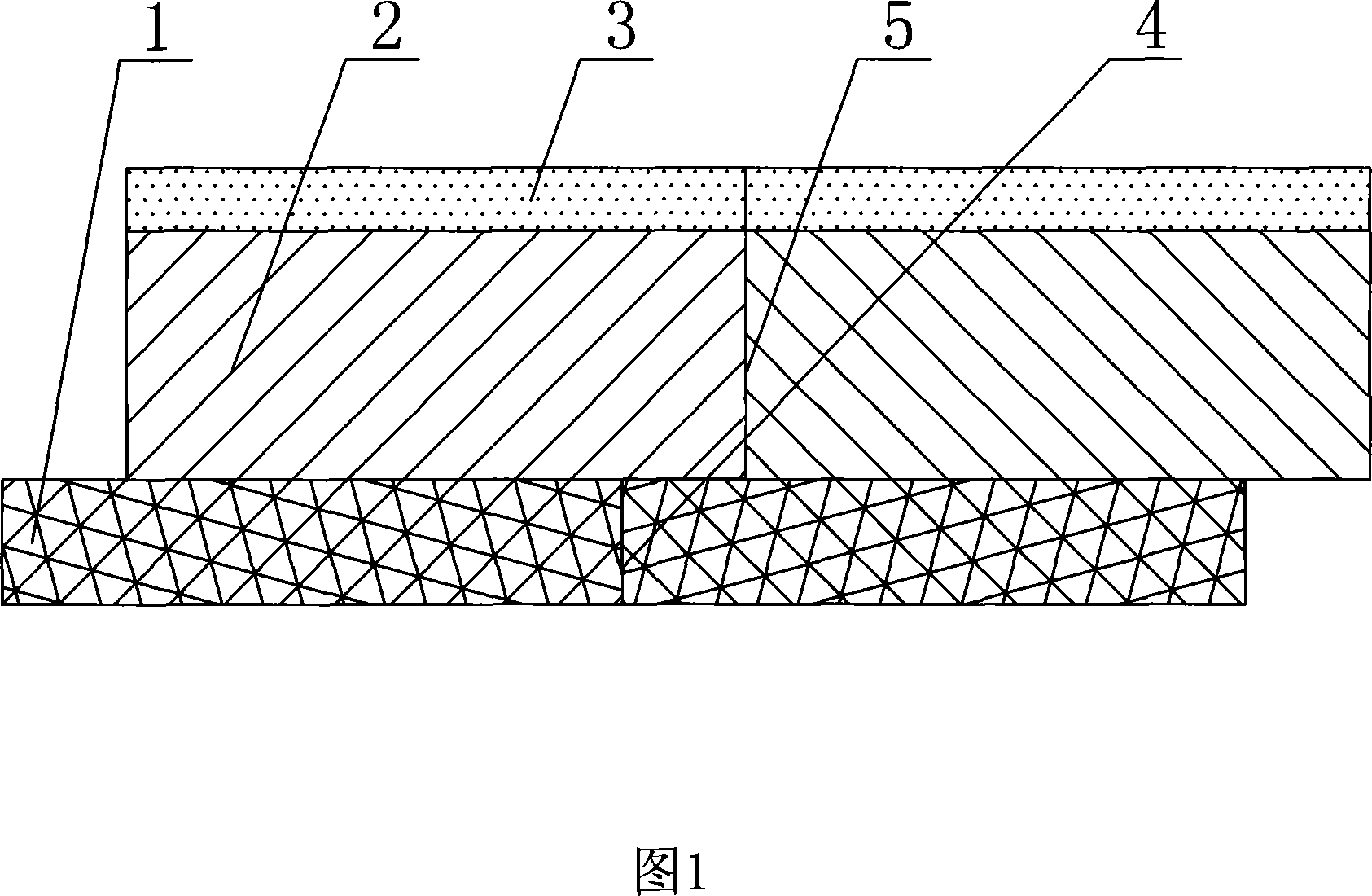

[0011] As shown in Figure 1, a plastic-based density composite floor comprises a plastic substrate 1, a layer of density board 2 is compounded on the plastic substrate 1, and a layer of wear-resistant surface layer 3 is coated on the density board 2, and the surface layer 3 Various patterns can be provided, and the edges of the plastic substrate 1 and the density board 2 are staggered from each other. The overlapping seams 5 between the density boards 2 are covered up.

[0012] The overlapping joints 5 between the upper density boards 2 are straight lines, while the overlapping joints 4 between the plastic substrates 1 can be straight lines and / or curved lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com