Gas detection method and gas detection device

A gas detection and gas technology, applied in the field of low-cost infrared gas detection, can solve the problems of slow measurement cycle, no absolute suppression technology, etc., and achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] As mentioned above, the present invention is based on the measurement technique described in the above two patent application documents.

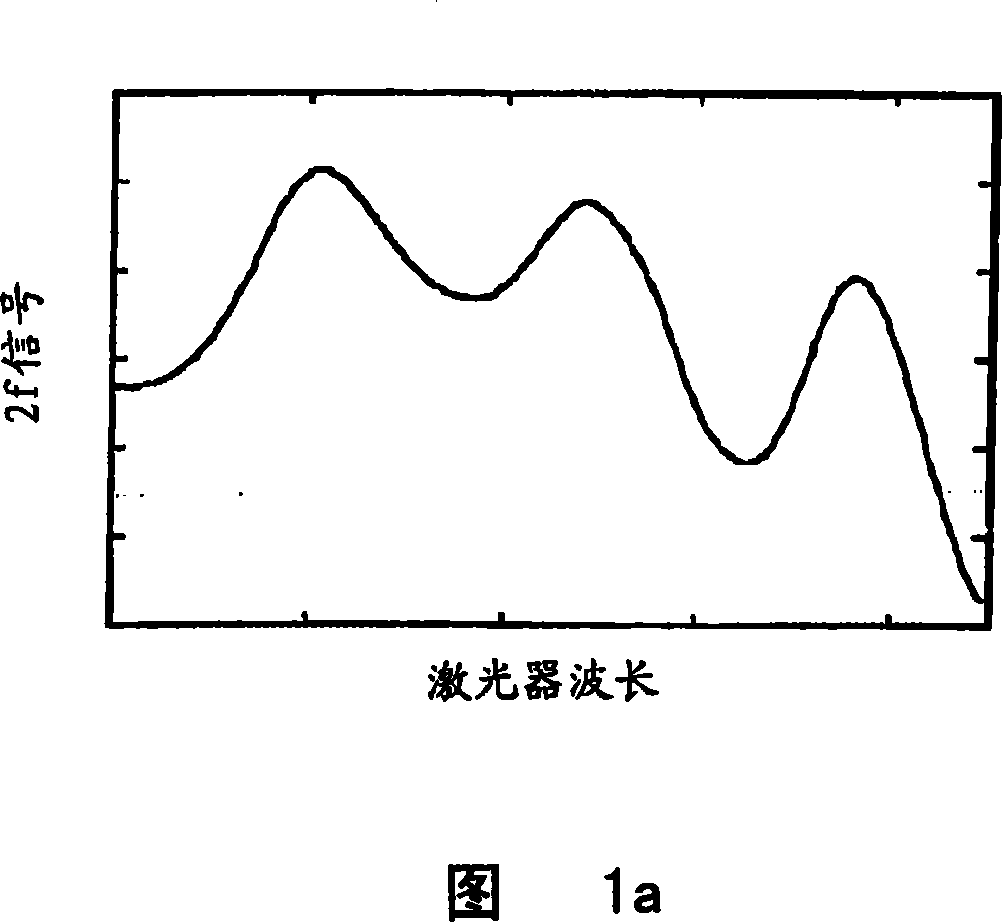

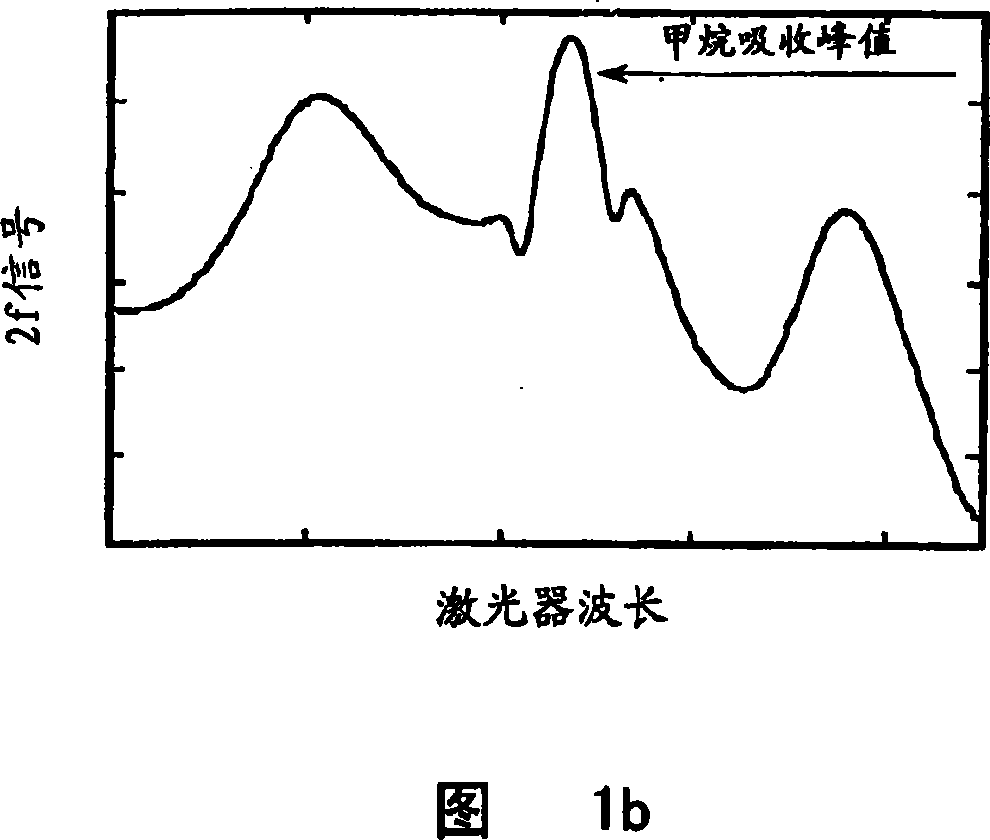

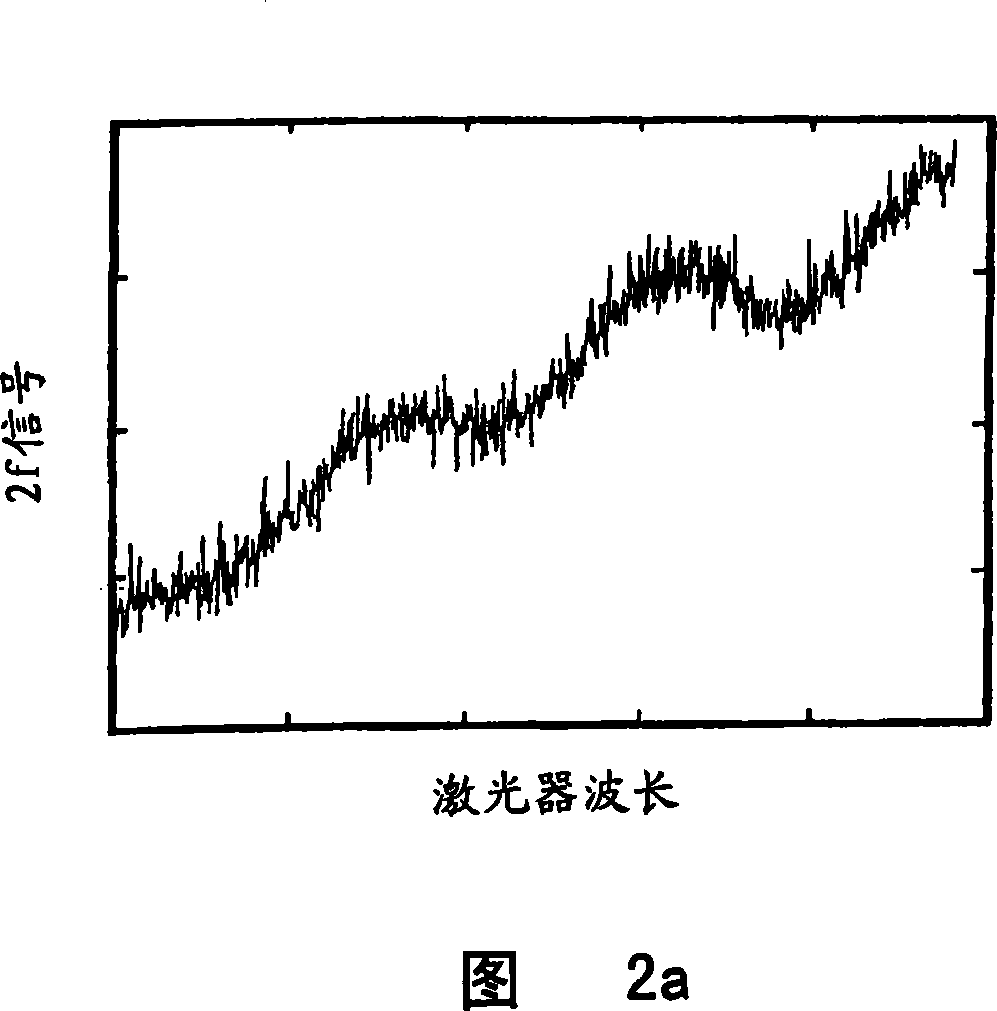

[0049] The tunable laser 1 is focused on the gas absorption peak of the measured gas by appropriate laser DC driving current. The temperature of the laser is usually kept at a constant value to avoid wavelength drift of the laser light caused by temperature changes of the laser. An AC current of frequency f is superimposed on the DC laser current so that the laser beam wavelength oscillates at frequency f around the gas absorption peak.

[0050]The laser light is emitted through the gas volume 4 containing the gas to be measured and is then incident on a photodiode as a detection device. The AC modulation of the laser drive current is connected to the intensity oscillations of the light output of the laser, which occur at the modulation frequency f. When a target gas is present in the gas absorption path, a portion of the laser lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com