Heat sinking control system and method

A technology of control system and control method, applied in the field of control, to achieve the effect of solving measurement lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

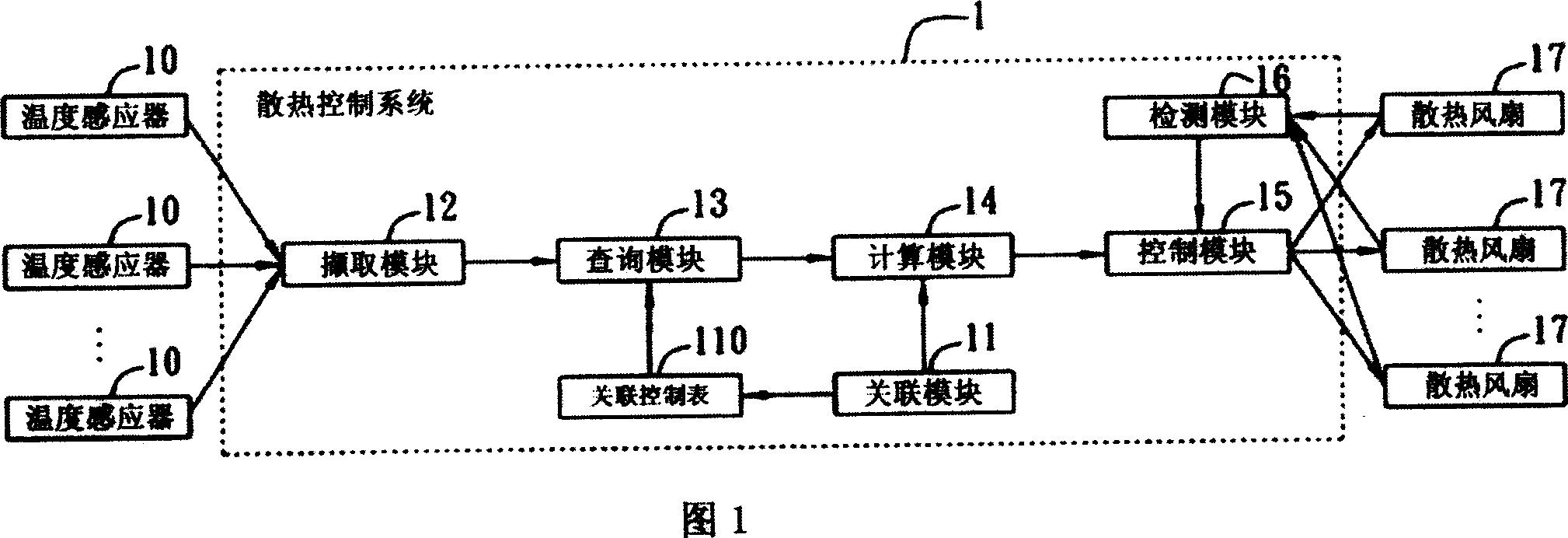

[0022] FIG. 1 is a schematic diagram of the detailed architecture of the heat dissipation control system of the present invention. As shown in the figure, the heat dissipation control system 1 of the present invention controls the operating state of at least one heat dissipation device such as a heat dissipation fan 17 according to the temperature value measured by at least one temperature sensor 10. In this embodiment, the heat dissipation fan 17 is set Cooling fans in server chassis. The heat dissipation control system includes an association module 11 , an acquisition module 12 , a query module 13 , a calculation module 14 , a control module 15 and a detection module 16 . In addition to the cooling fan, the heat dissipation device is also a liquid cooling system. The heat dissipation control system of the present invention can control the pump body of the liquid cooling system to process the flow rate of the cooling liquid. In the following embodiments, the cooling fan is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com