Motor and pump having magnetic sensor, connecting method between circuit board having magnetic sensor and stator, and manufacturing method of motor and pump

A circuit board and stator technology, applied in the manufacture of pumps, pumps that circulate water, and the field of motor vehicles, can solve problems such as water leakage, loss, and damage to the Hall element 9a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]

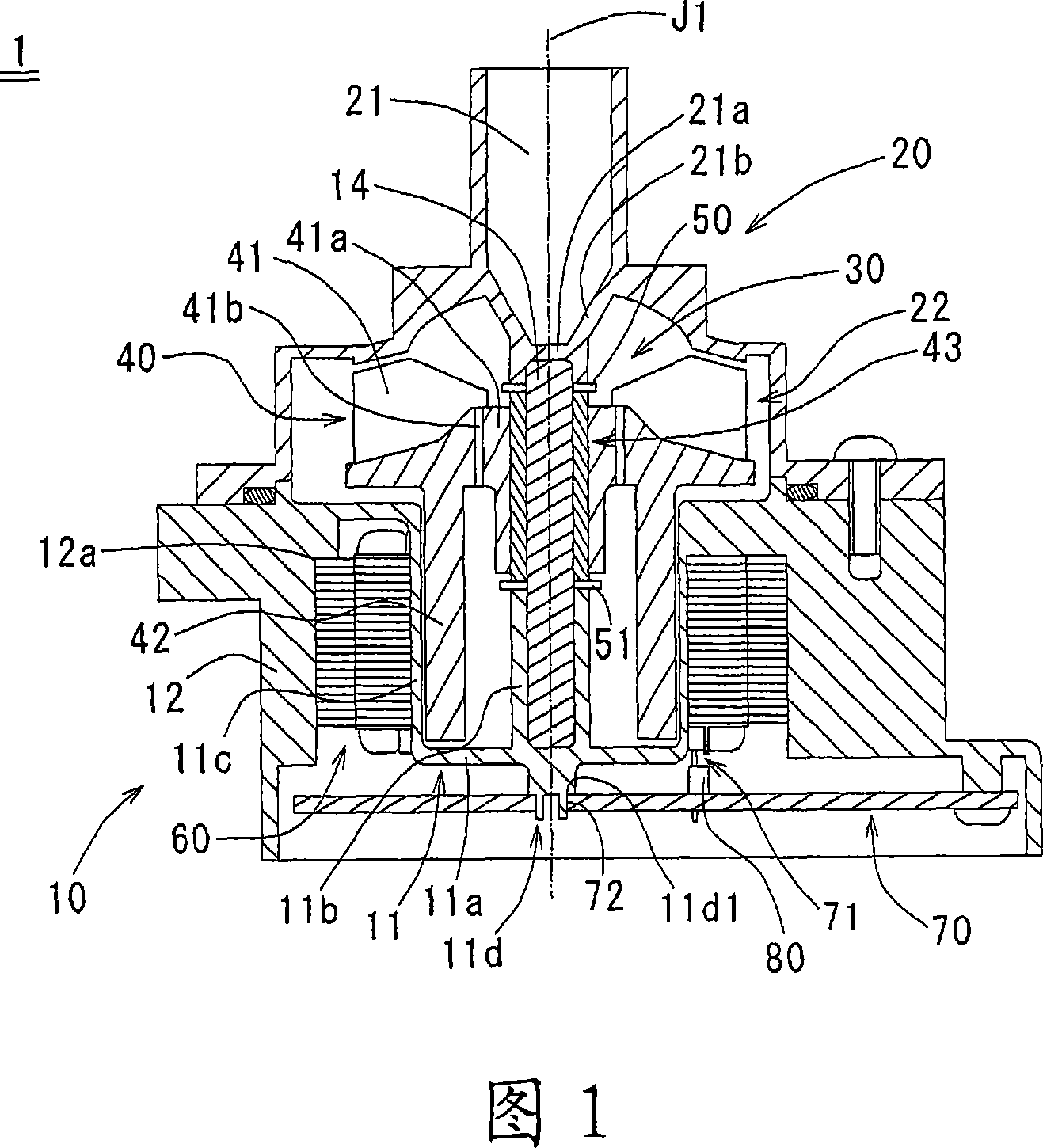

[0027] A first preferred embodiment of the pump according to the invention will be described below with reference to FIG. 1 . FIG. 1 is a schematic cross-sectional view of a pump 1 . It should be noted that in the description of the preferred embodiments herein, terms such as up, down, left, right, up, down, top, and bottom used to describe the positional relationship and direction between the corresponding parts refer only to those shown in the drawings. position and direction. These terms do not refer to the positional relationship and orientation of components mounted in an actual device. And it should be noted that the reference numerals, figure numbers and supplementary explanations presented below are used to help readers find corresponding components in the description of the following preferred embodiments, so as to facilitate understanding of the present invention. It should be understood that these expressions in no way limit the scope of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com