Mechanism for forming a shed, weaving loom equipped with such a mechanism and method of selecting the mobile hook of such a mechanism

A technology of movable hooks and looms, which is applied in textiles, jacquard machines, textiles and papermaking, etc., and can solve the problems of reducing the overall economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

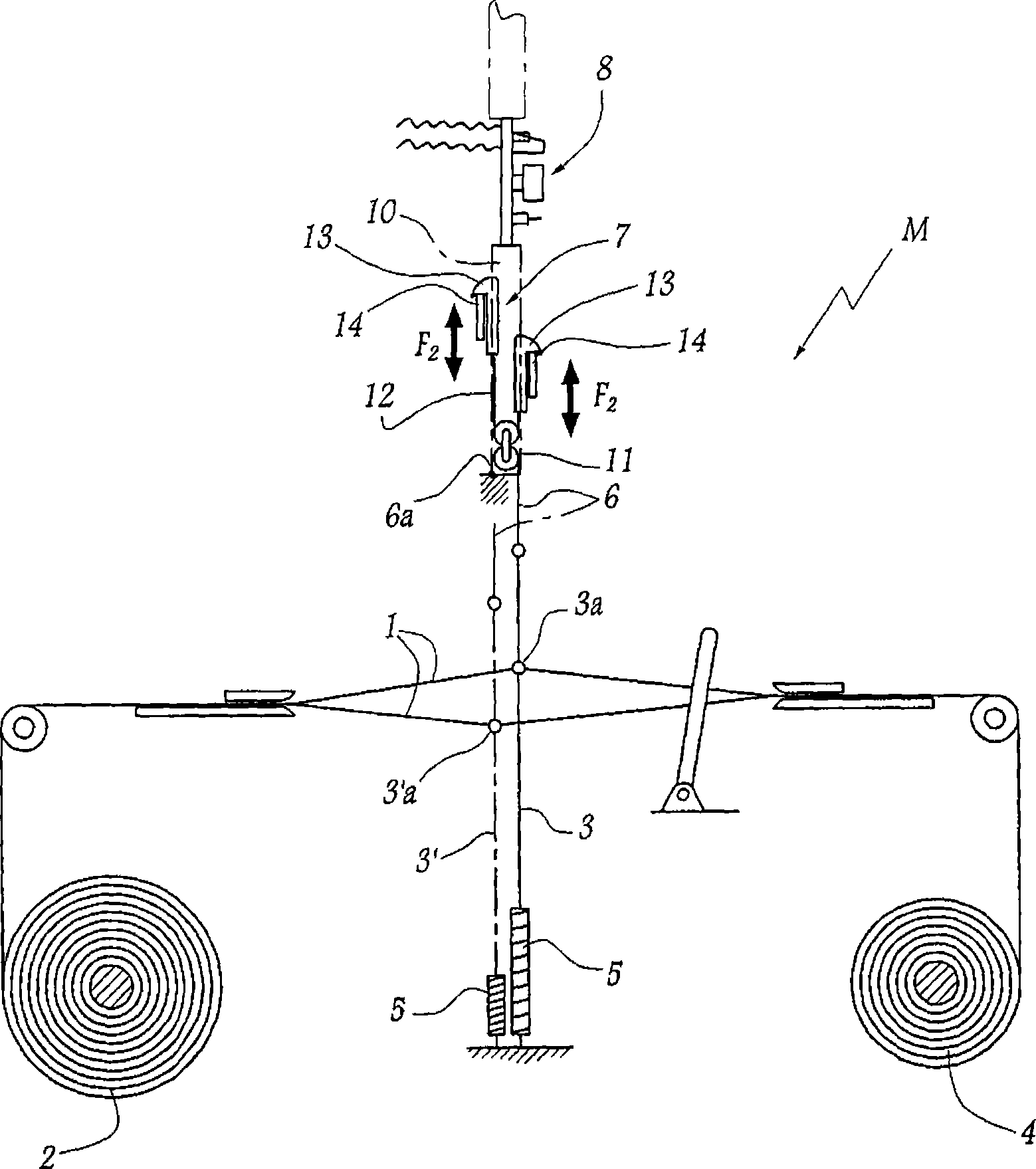

[0026] figure 1 In the loom M shown, a piece of warp yarn 1 is drawn from a reel 2 . Each warp thread 1 passes through an eyelet 3a in the heddle 3 to open the way for the weft thread to pass through, so as to make the fabric wound on the reel 4 . figure 1 Only two healds 3 and 3' are shown in Fig. 2, with heald 3 in the high position and heddle 3' in the low position. The bottom end of each heddle is connected to the structural member of the loom via a tension spring 5 , while its top end is fixed to a harness 6 .

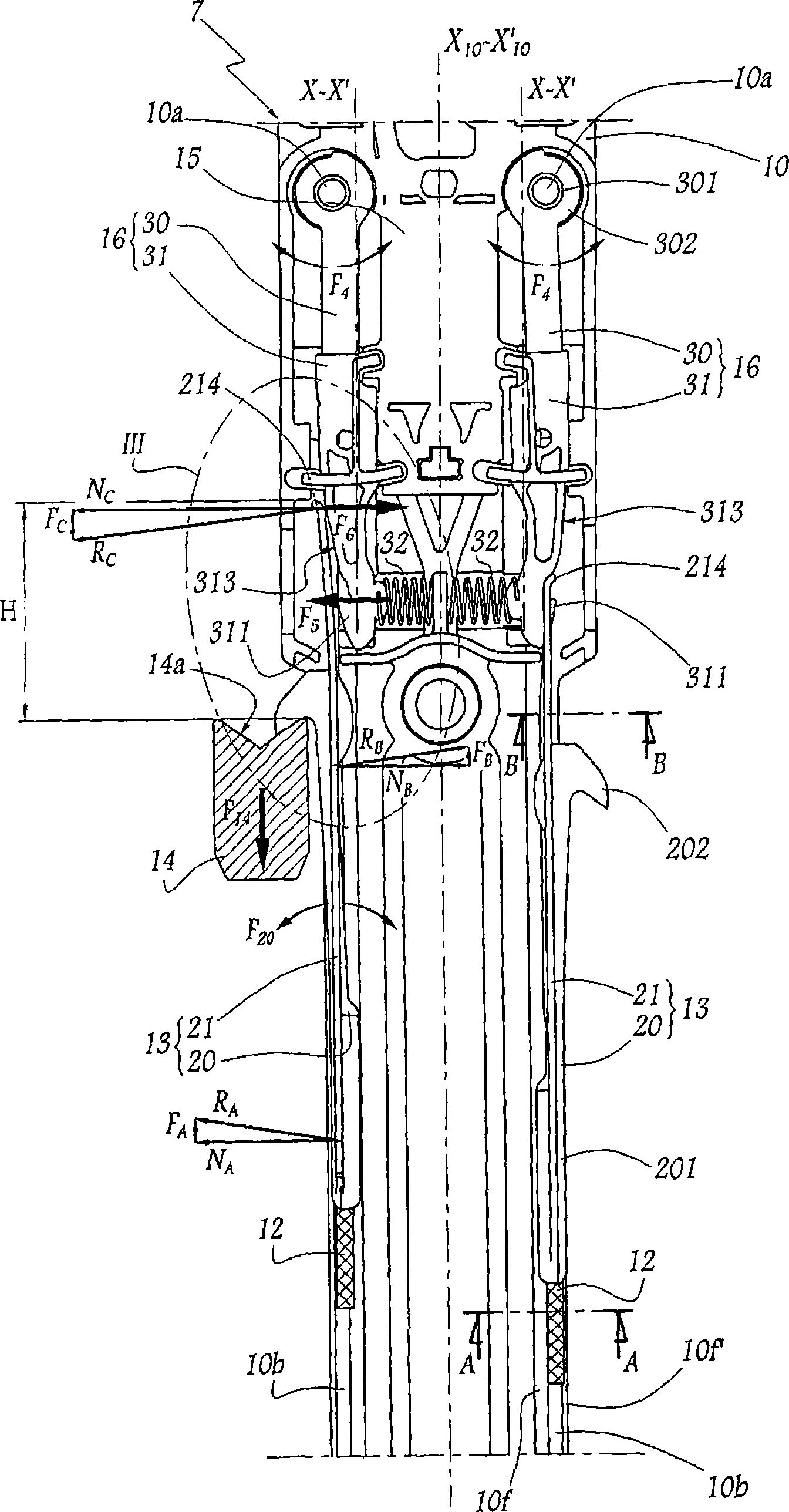

[0027] The shedding mechanism 7 associated with the electronic control unit 8 serves to lift the harness 6 more or less against the return force exerted by the spring 5 . Only the harness 3 associated with the heald is shown in the figure, one end 6a of the harness is fixed to the housing 10 of the mechanism 7, and the harness passes through the pulley block 11 suspended on the suspension rope 12, and the two ends of the suspension rope 12 are respectively fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com