External vehicle fuel tank fuel quantity precision metering container device

An external type and oil tank technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of difficult on-site implementation, inaccurate oil volume management, high labor intensity, etc., to achieve stability and balance, eliminate liquid level measurement dead zone, Guarantee the effect of effective travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The measurement signal of the high-precision liquid level sensor is input to the display device, and

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

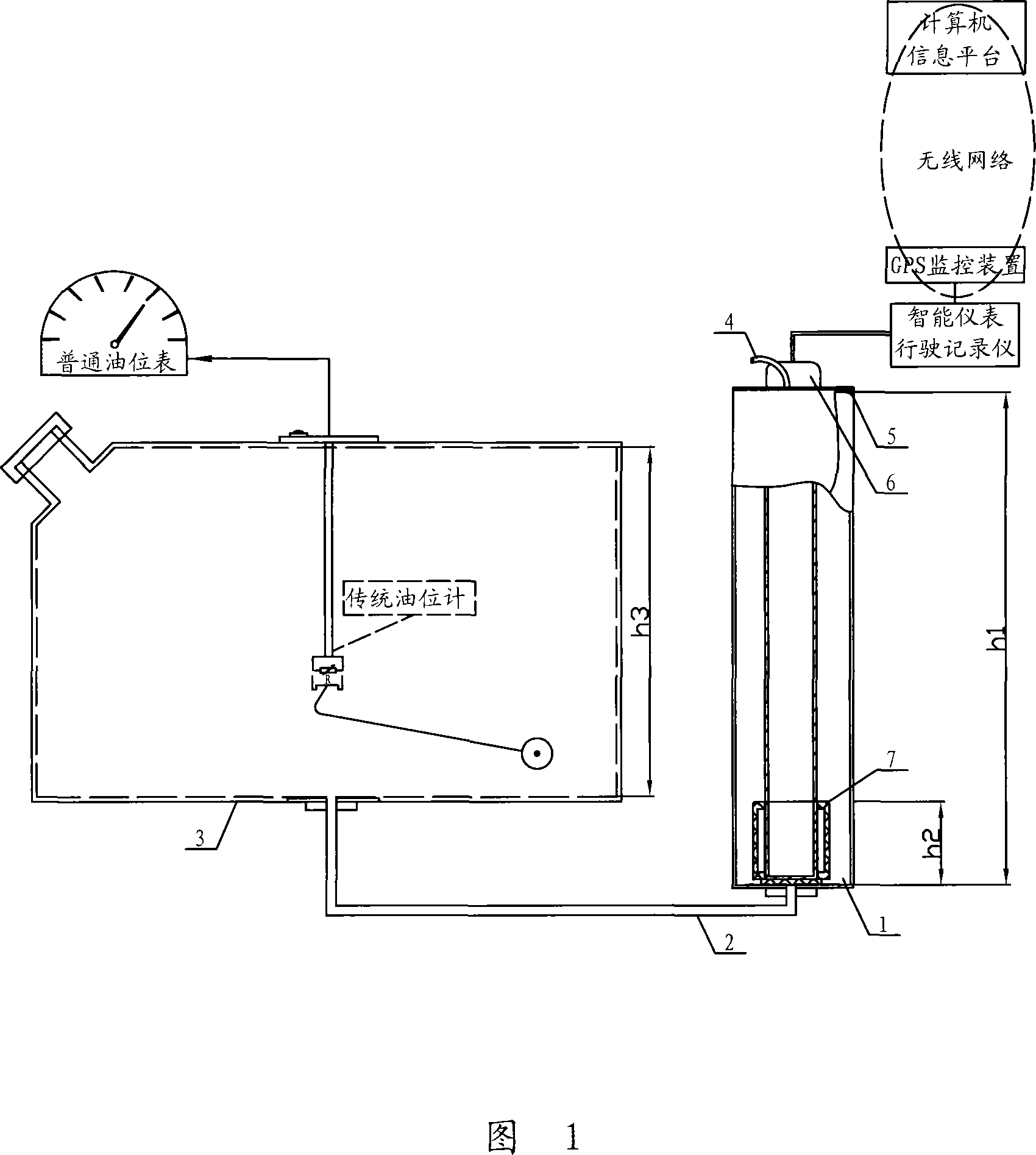

[0017] As shown in Figure 1, a precision metering container device for an externally connected fuel tank of a vehicle includes a display device and a fuel tank 3. It is characterized in that the fuel tank 3 is externally connected to a metering container 1, and a high-precision liquid level is set in the metering container. Sensor 6, the bottom of the metering container communicates with the oil outlet at the bottom of the fuel tank 3 through a connecting pipe 2; the measurement signal of the high-precision liquid level sensor is input to the display device, which can be monitored by a GPS monitoring device with wireless communication function Remote transmission to the computer information management platform. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com