Method for processing nylon zipper and zipper stopper and zipper stopper welder

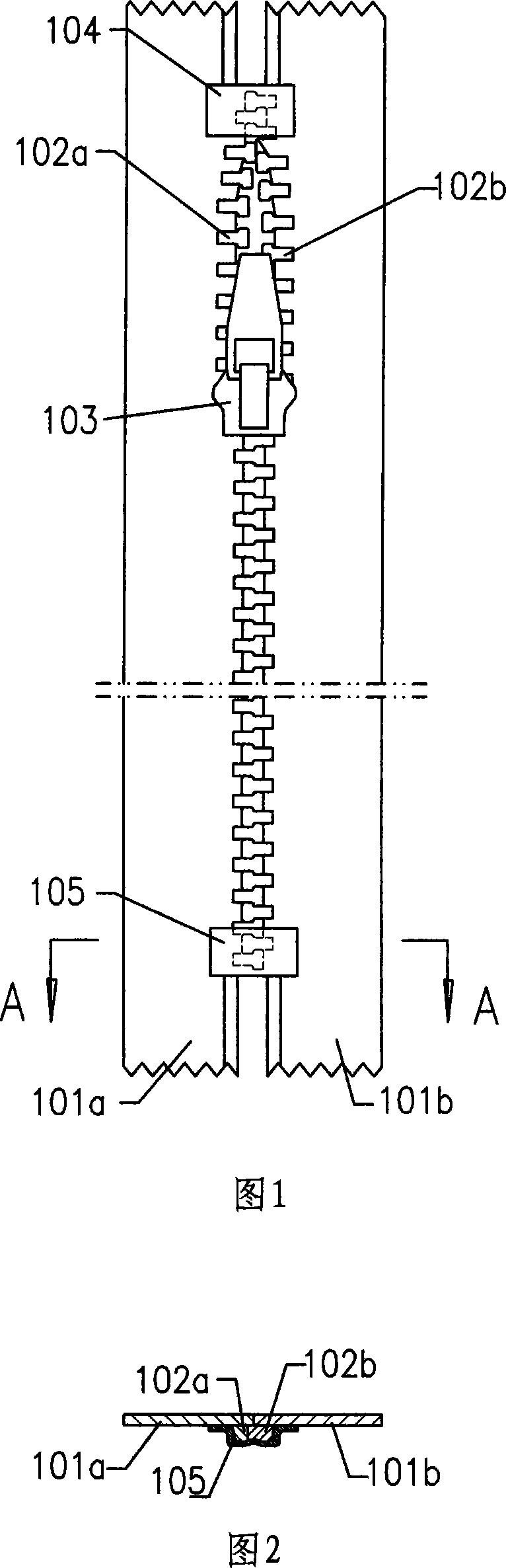

A welding machine and zipper technology, applied in the field of zipper, can solve the problems of zipper not easy to lay flat, nylon material is hard, metal buckle scratches clothes, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

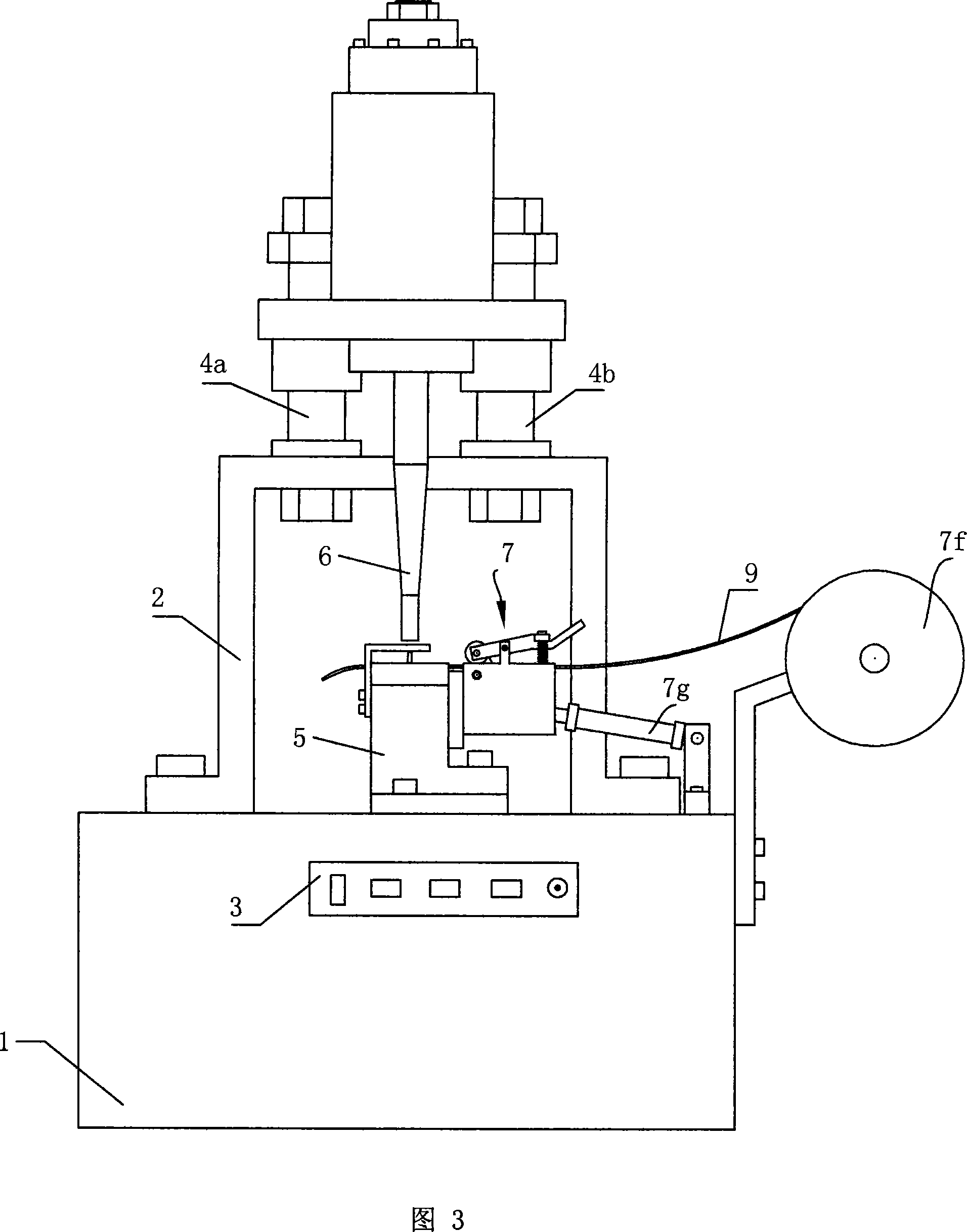

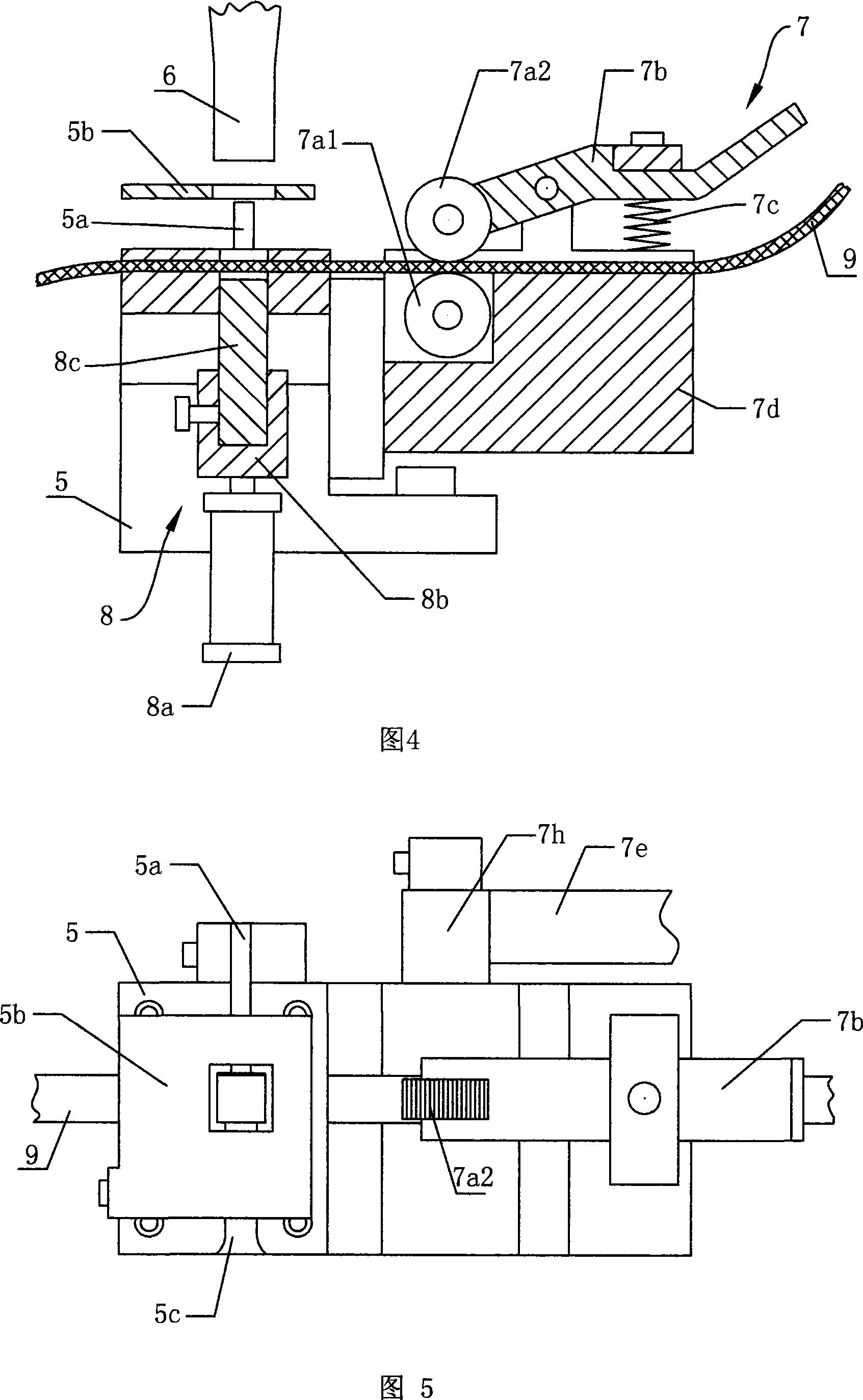

[0028] The zipper buckle welding machine, as shown in Figure 3, comprises a machine base 1, a support 2 fixed on the top of the machine base 1, and a workbench 5, and the workbench 5 is provided with a guide hole for cutter guidance in the welding area, A groove 5c that can accommodate a zipper chain is provided on the upper part, and a zipper limiting block 5a is fixed at the end of the groove 5c. It also includes a feeding device 7 for feeding the sheet plastic strip 9 to the welding area of the workbench 5, a cutting device 8 for die-cutting the plastic strip 9 located in the welding area, a guide fixed on the support 2 Columns 4a, 4b, plastic welding head 6 used for welding the die-cut plastic sheet to the end of the zipper tooth chain, slidingly sleeved on the guide column 4a, 4b, the plastic welding head 6 is preferably an ultrasonic plastic welding head , the first power device (not shown in the figure) installed on the bracket 2 for driving the plastic welding head 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com