Rotor blade for wind energy plants

A technology for rotor blades and wind energy equipment, which is applied in wind power generation, mechanical equipment, and wind turbines in the same direction as the wind. It can solve the problems of increasing the necessary cost of materials, and achieve the effects of reduced risk, reduced bending stress, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

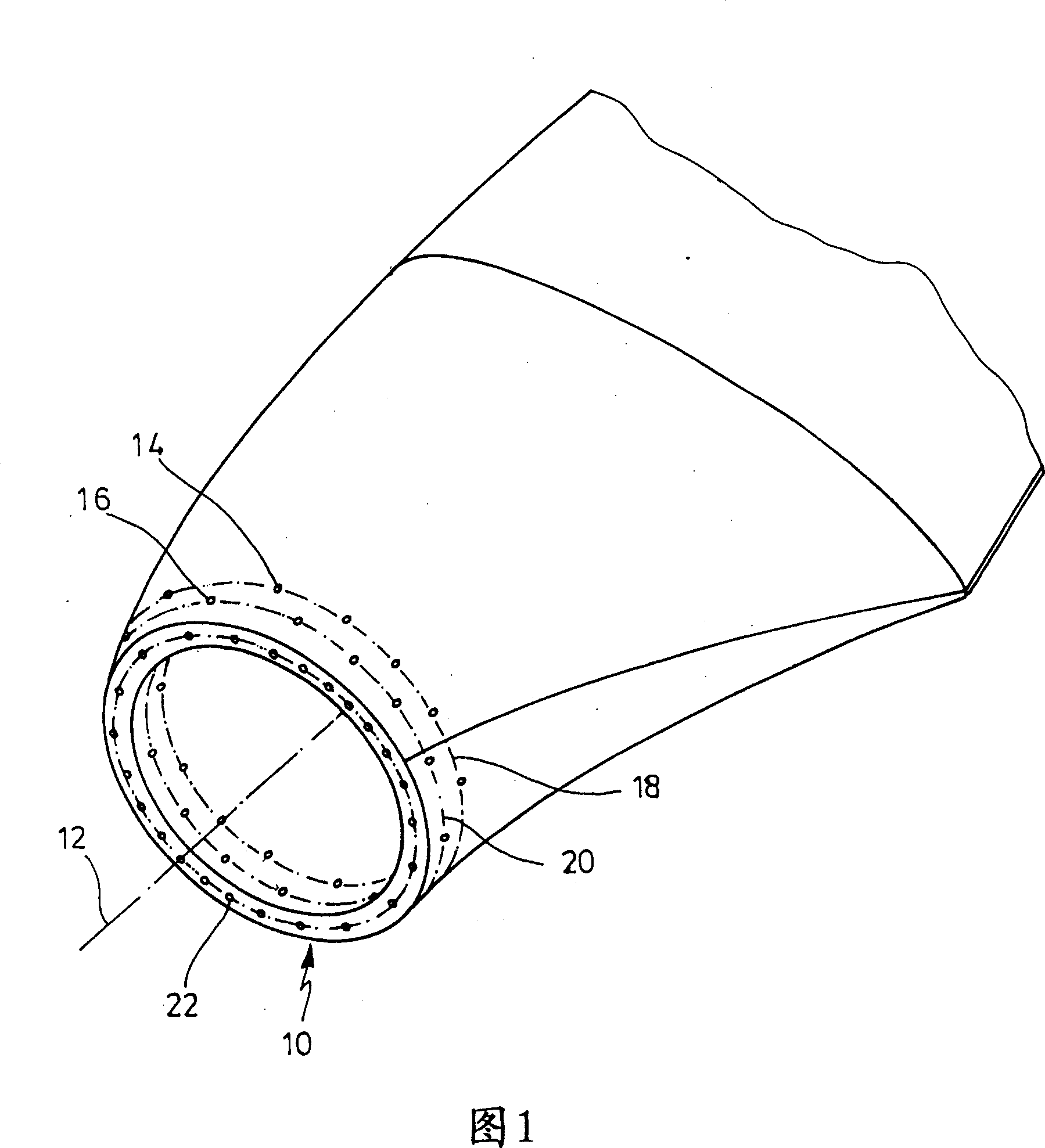

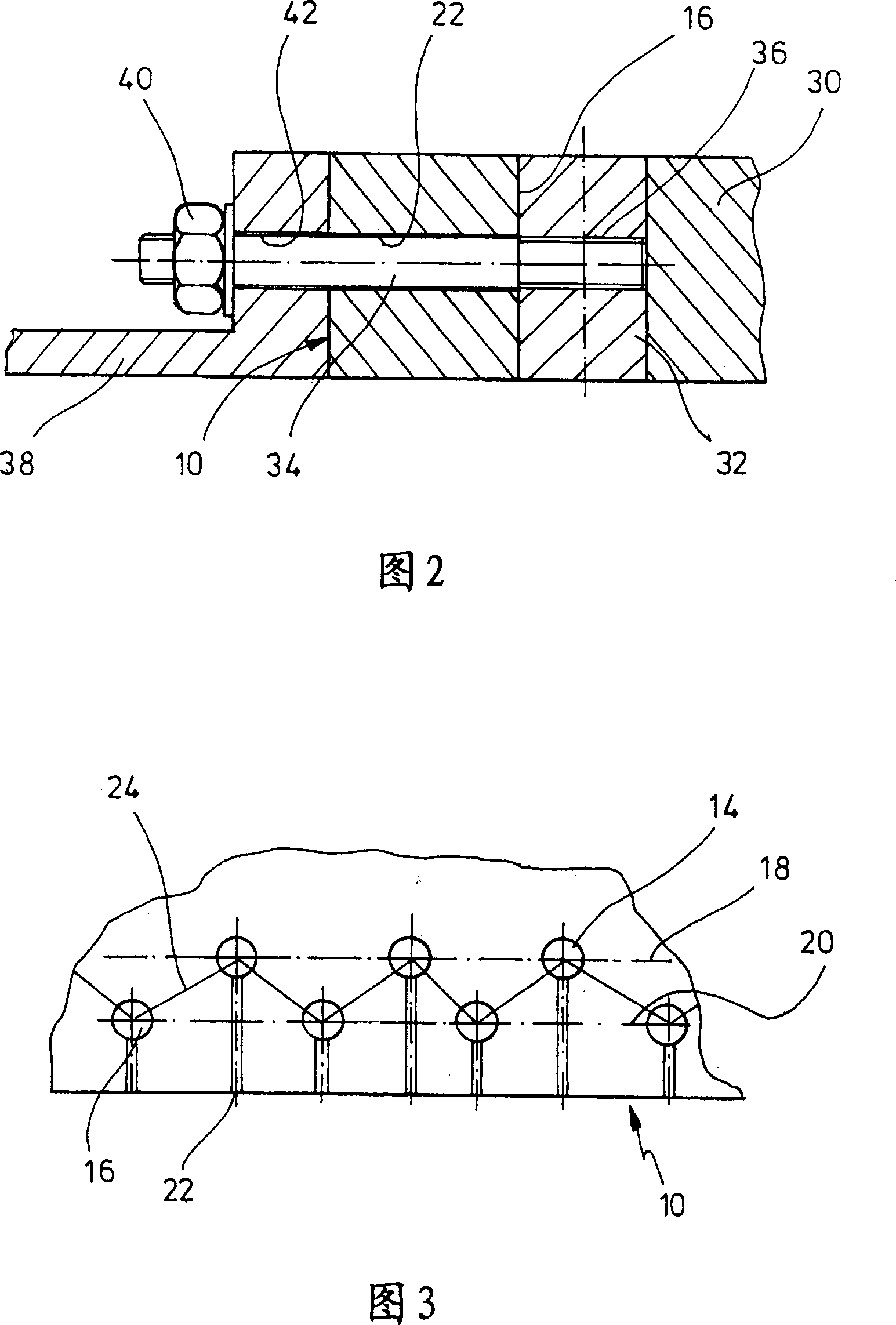

[0025] The blade base of the rotor blade is drawn in FIG. 1 , and the rotor blade consists of two shell halves made of fiber-reinforced plastic material in a manner known per se. On the hub-side end of the rotor blade there is a hub-side rotor blade edge 10 which is formed by an approximately circular annular plane. The width of the ring corresponds to the material thickness of the rotor blade shell in this region. The longitudinal axis of the rotor blade is indicated at 12 . The hub-side rotor blade edge 10 is aligned substantially perpendicular to the longitudinal axis 12 .

[0026] The rotor blade is provided with a plurality of transverse holes 14 , 16 . In the example shown, the transverse holes 14 , 16 are aligned transversely, approximately perpendicularly, to the longitudinal axis 12 of the rotor blade. However, depending on the shape of the rotor blade and the shape of the rotor blade fastening means 38 (not shown in FIG. 1 ) close to the hub of the wind energy ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com