Noise reduction and rectification flow regulating valve for pipeline natural gas

A flow control valve, natural gas technology, applied in the valve's device for absorbing fluid energy, lift valve, valve details, etc., can solve the problems of laminar flow, turbulent flow, ultrasonic measurement interference, unstable flow rate, etc., and achieve a compact structure. , Overcome the effect of occupying a large space and reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

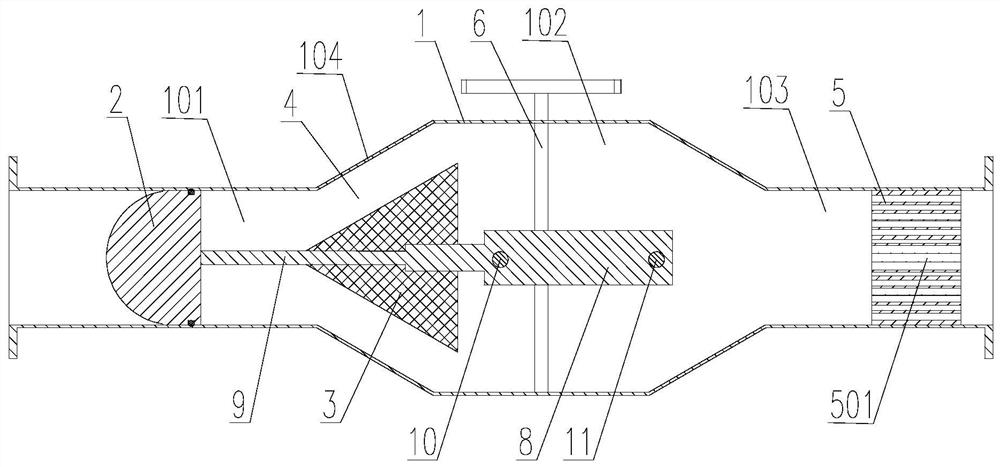

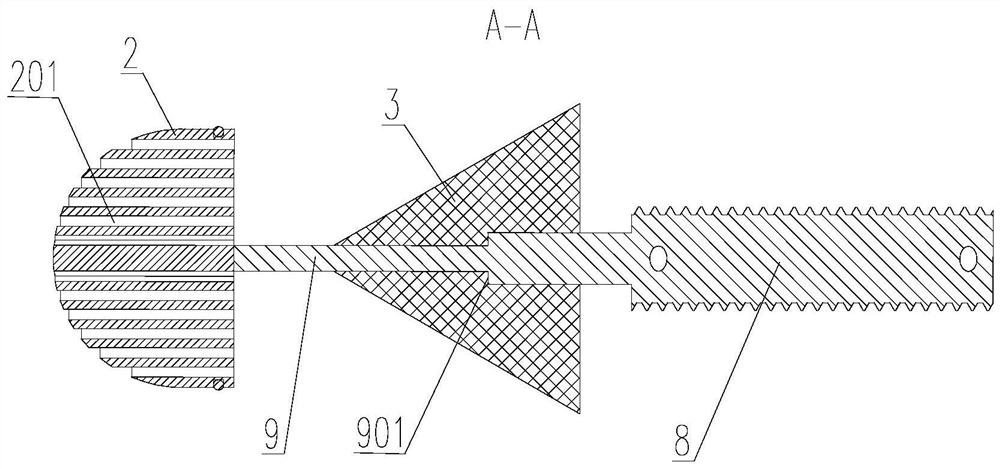

[0039] Such as Figure 1-5 As shown, a pipeline natural gas noise reduction rectification flow regulating valve includes a valve body 1 with a valve cavity 102, a front rectifier 2, a valve core 3, a rear rectifier 5 and a driving mechanism. The front end of the valve body 1 has a The air intake channel 101 communicated with the cavity 102, the rear end of the valve body 1 has an air outlet channel 103 communicated with the valve cavity 102, and the valve core 3 is located in the valve cavity 102;

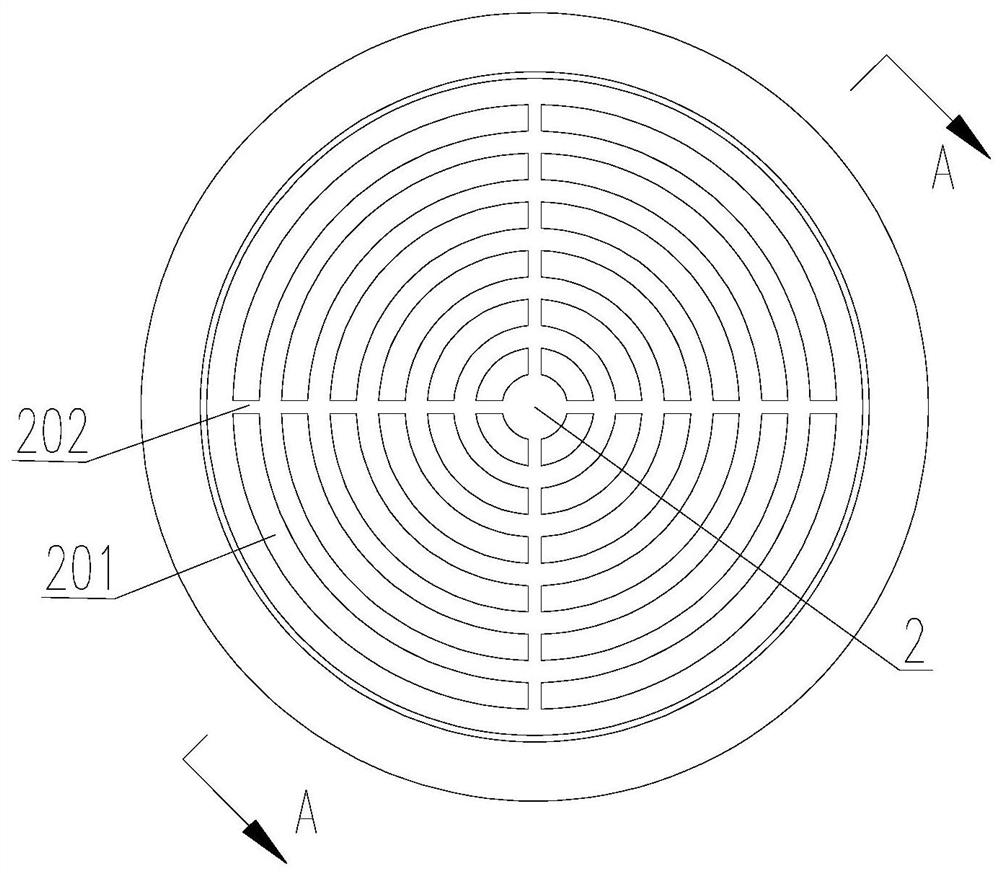

[0040] The front rectifying body 2 is installed in the air intake channel 101, and its front end face is a hemispherical surface. The front rectifying body 2 runs through a plurality of rectifying channel groups along the axial direction of the air intake channel 101, and each rectifying channel group All have a plurality of rectification channels 201 located in the same radial direction of the front rectifier body 2, and the plurality of rectification channel groups are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com