Sound insulation type building material and processing method thereof

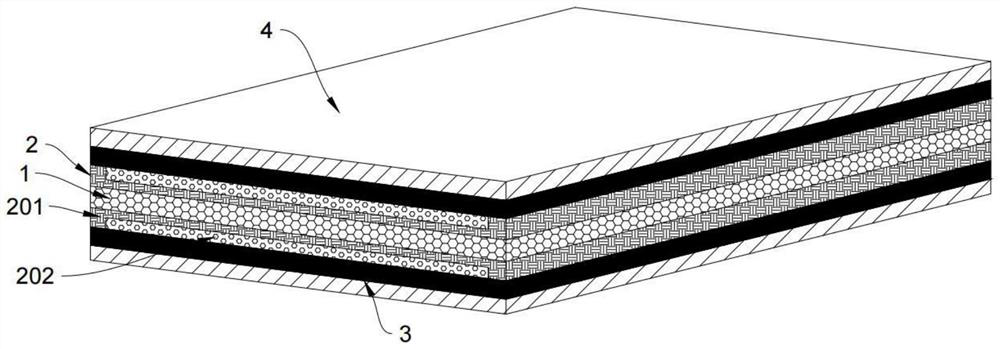

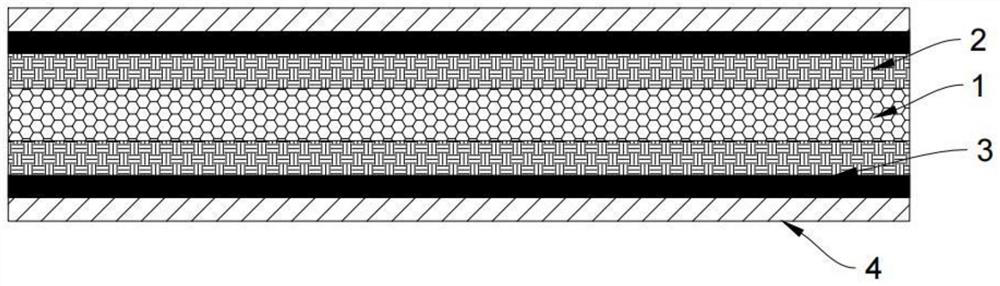

A technology of building materials and sound insulation layers, applied in the direction of sound insulation, building components, building elements, etc., can solve the problems of inability to achieve good sound insulation, reduce sound penetration, and limited sound insulation effect, so as to ensure the privacy of life and enhance The effect of weakening the sound and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The outer layer includes the following raw materials by weight: 30 parts of ceramsite, 10 parts of wood fiber, 40 parts of perlite powder, 7 parts of diatomaceous earth, 5 parts of magnesium oxide powder, 4 parts of microcrystalline stone, 50 parts of fly ash, 3 parts of calcium oxide, 30 parts of flame retardant and 8 parts of stabilizer.

Embodiment 2

[0033] The outer layer includes the following raw materials by weight: 50 parts of ceramsite, 15 parts of wood fiber, 50 parts of perlite powder, 12 parts of diatomaceous earth, 9 parts of magnesium oxide powder, 8 parts of microcrystalline stone, 60 parts of fly ash, 7 parts of calcium oxide, 40 parts of flame retardant and 12 parts of stabilizer.

Embodiment 3

[0035] The outer layer includes the following raw materials by weight: 40 parts of ceramsite, 12 parts of wood fiber, 45 parts of perlite powder, 10 parts of diatomaceous earth, 7 parts of magnesium oxide powder, 6 parts of microcrystalline stone, 55 parts of fly ash, 5 parts of calcium oxide, 35 parts of flame retardant and 10 parts of stabilizer.

[0036] The outer layer is prepared as follows:

[0037] A: Weigh the required amount of ceramsite, wood fiber, perlite powder, diatomaceous earth, magnesium oxide powder, microcrystalline stone, fly ash, calcium oxide, flame retardant and stabilizer, and set aside;

[0038] B: Pour the ceramsite, wood fiber, perlite powder, diatomaceous earth, magnesium oxide powder, microcrystalline stone, fly ash, and calcium oxide weighed in step A into the mixing tank and stir until they are mixed uniform;

[0039] C: Pour the flame retardant and stabilizer weighed in step A into the stirring tank together, and stir again until the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com