Flame detection device and method of detecting flame

A flame detection device and flame technology, applied in the field of flame devices, can solve the problems of not being able to detect multiple fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

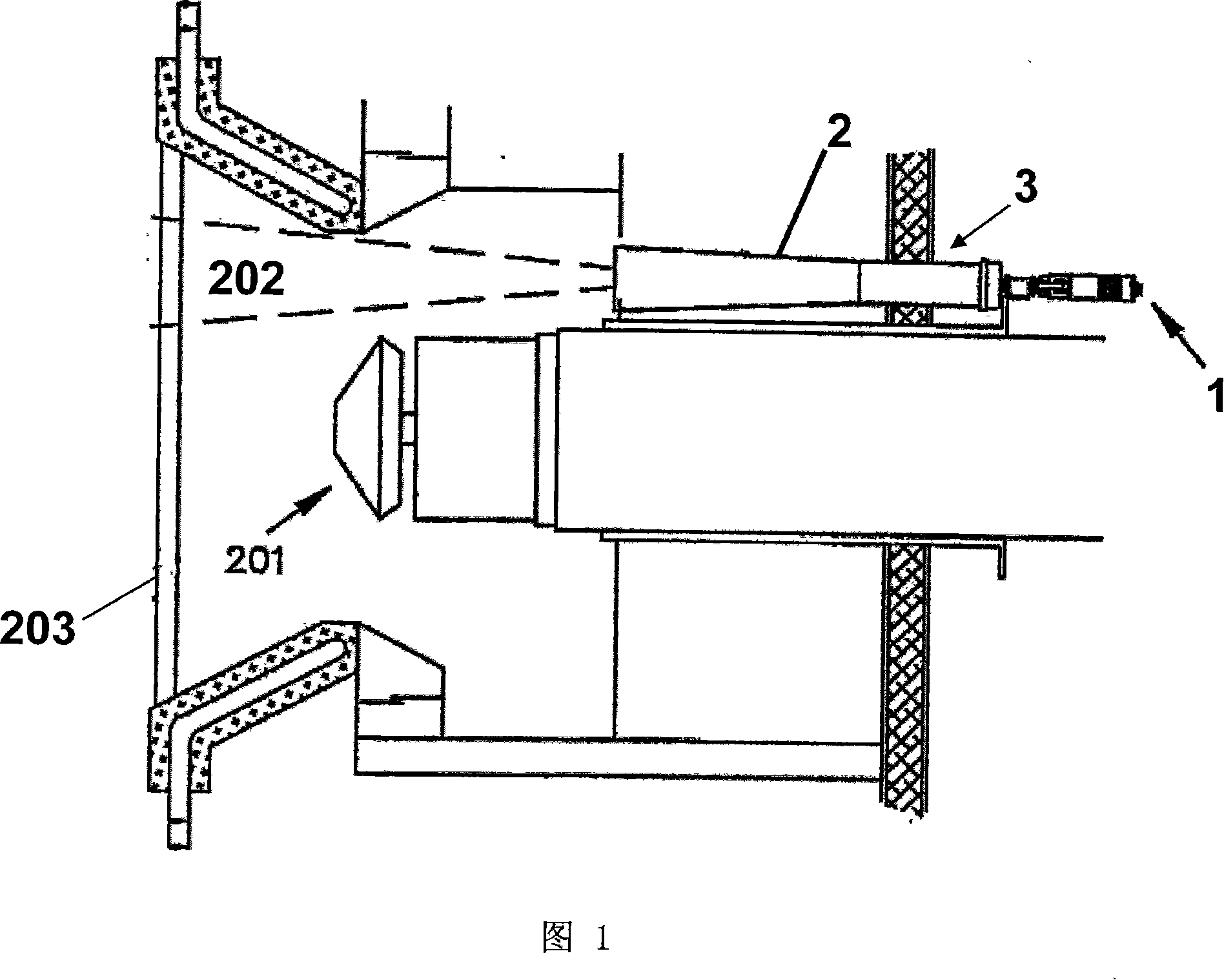

[0027] As shown in FIG. 1 , the flame detection device 1 is arranged at the proximal end of the observation tube 2 . Viewing tube 2 and viewfinder optics associated therewith are constructed using conventional means, such as disclosed in US Pat. No. 5,107,128. As stated therein, the sight tube 2 is arranged in the burner viewing hole 3 of the boiler furnace so that the distal end of the sight tube 2 is close to the flame area 202 produced by the burner 201 . For ease of description, a single burner 201 is shown in FIG. 1 . However, the flame detection device of the present invention can also be applied in multi-burner systems.

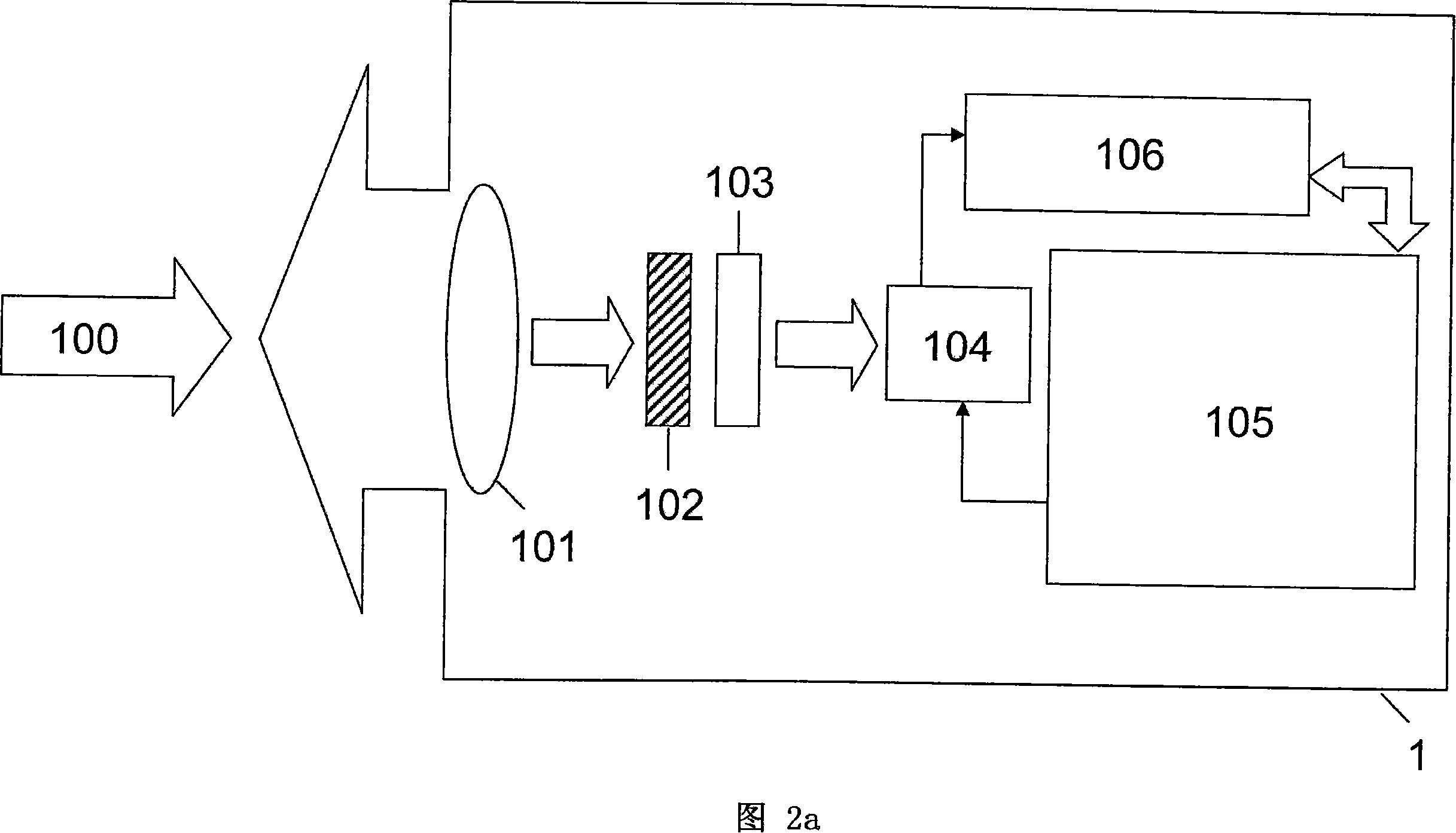

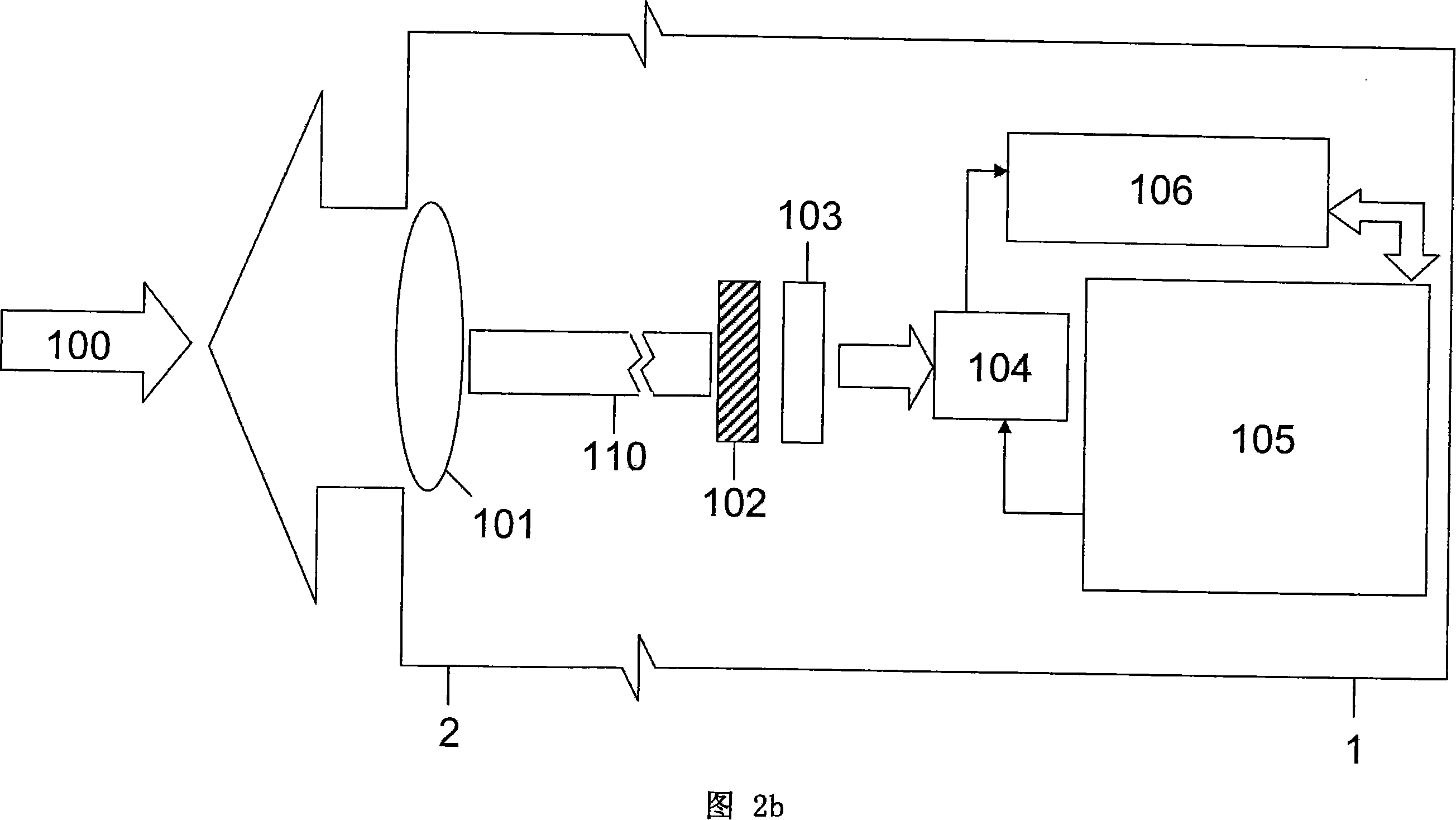

[0028] An exemplary embodiment of a flame detection device 1 according to the invention is described in detail with reference to FIG. 2a. The projected flame 100 represents the flame area 202 within the line of sight of the flame detection device 1 (as seen through the sight tube 2 shown in FIG. 1 ), which includes the flame produced by the burner of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com