Radiating device and radiating system using same

A technology of heat dissipation device and heat dissipation system, which is applied in the cooling of instruments, instrument parts, cooling/ventilation/heating renovation, etc. Effective heat dissipation area, good ventilation, and the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

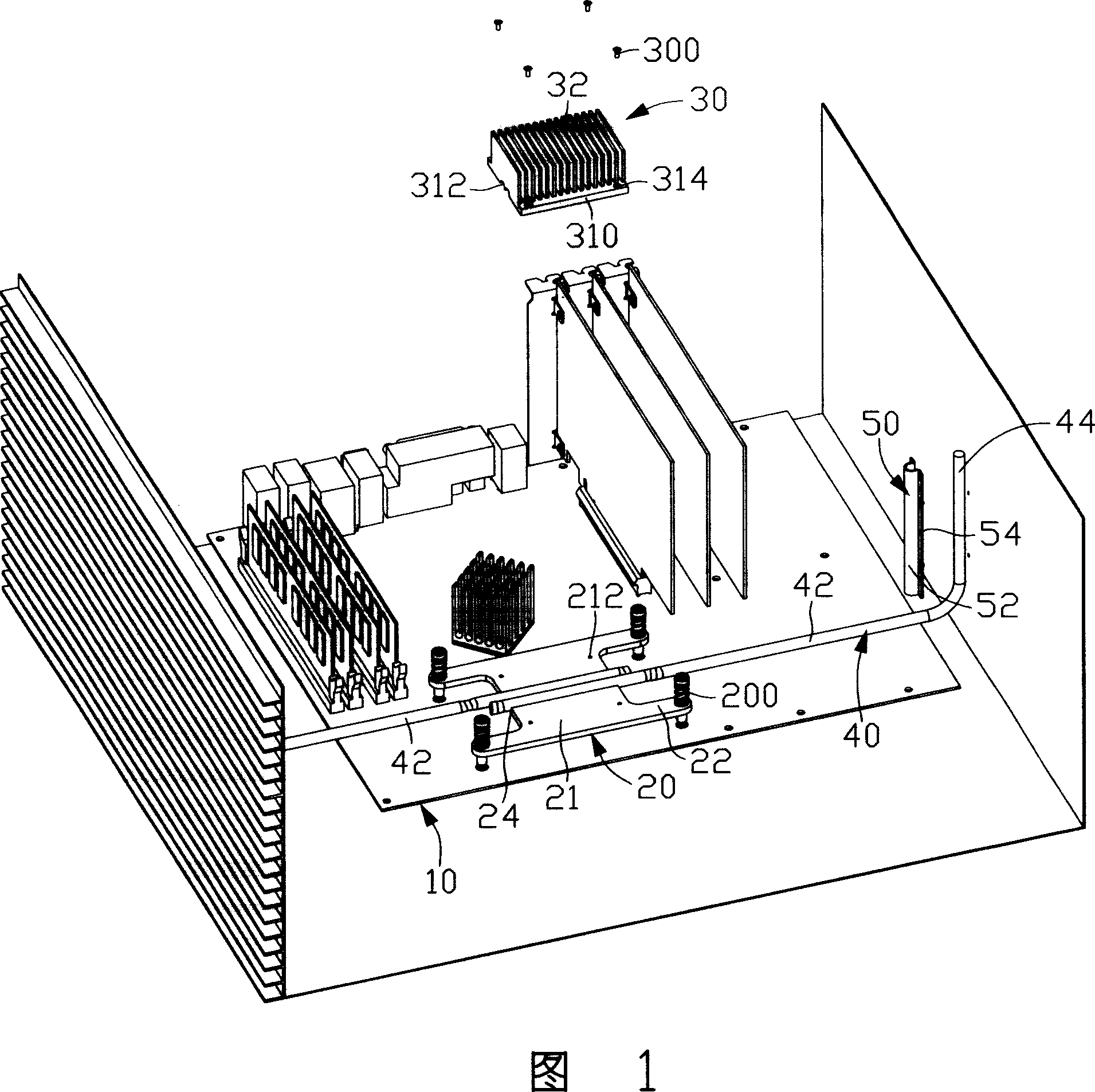

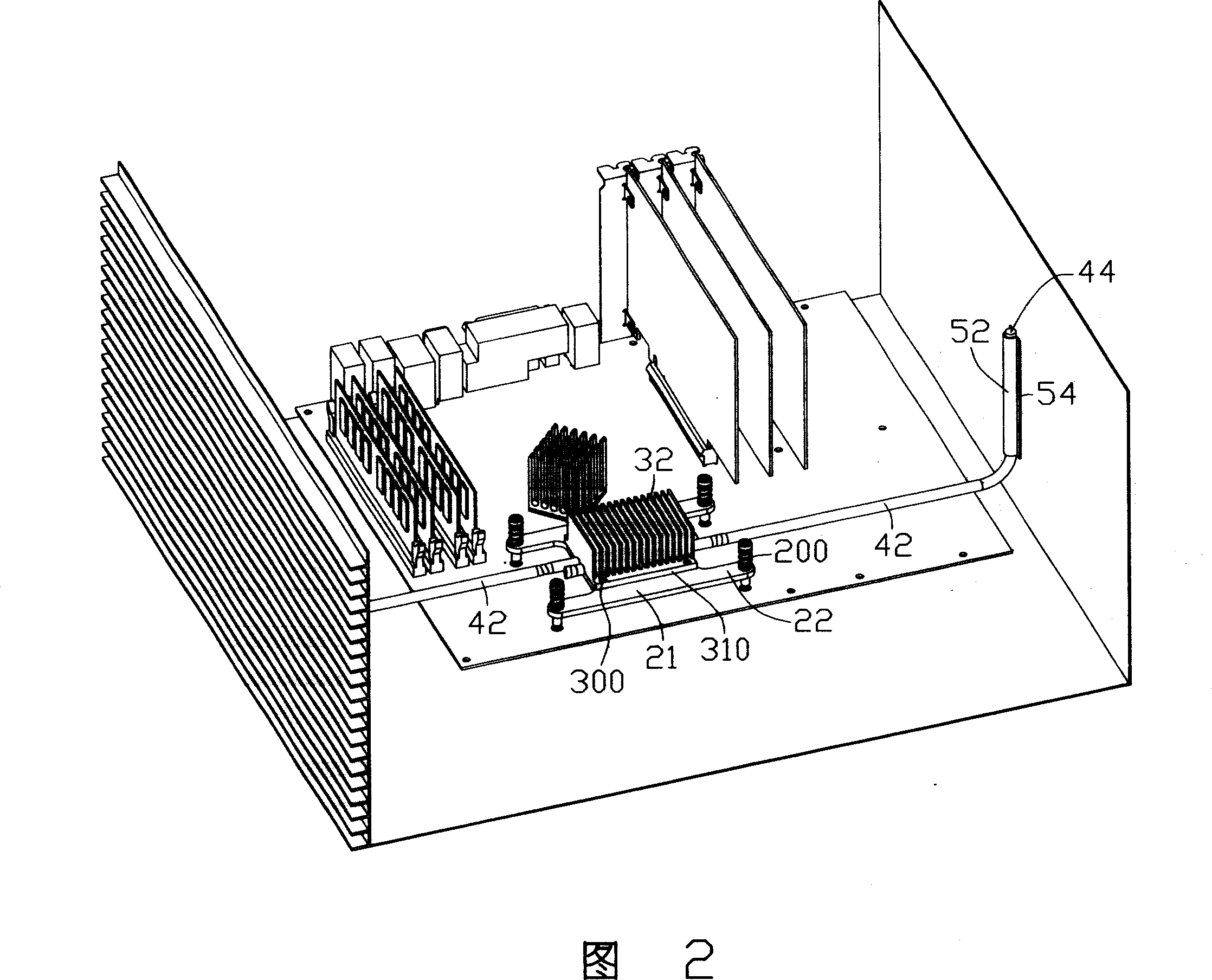

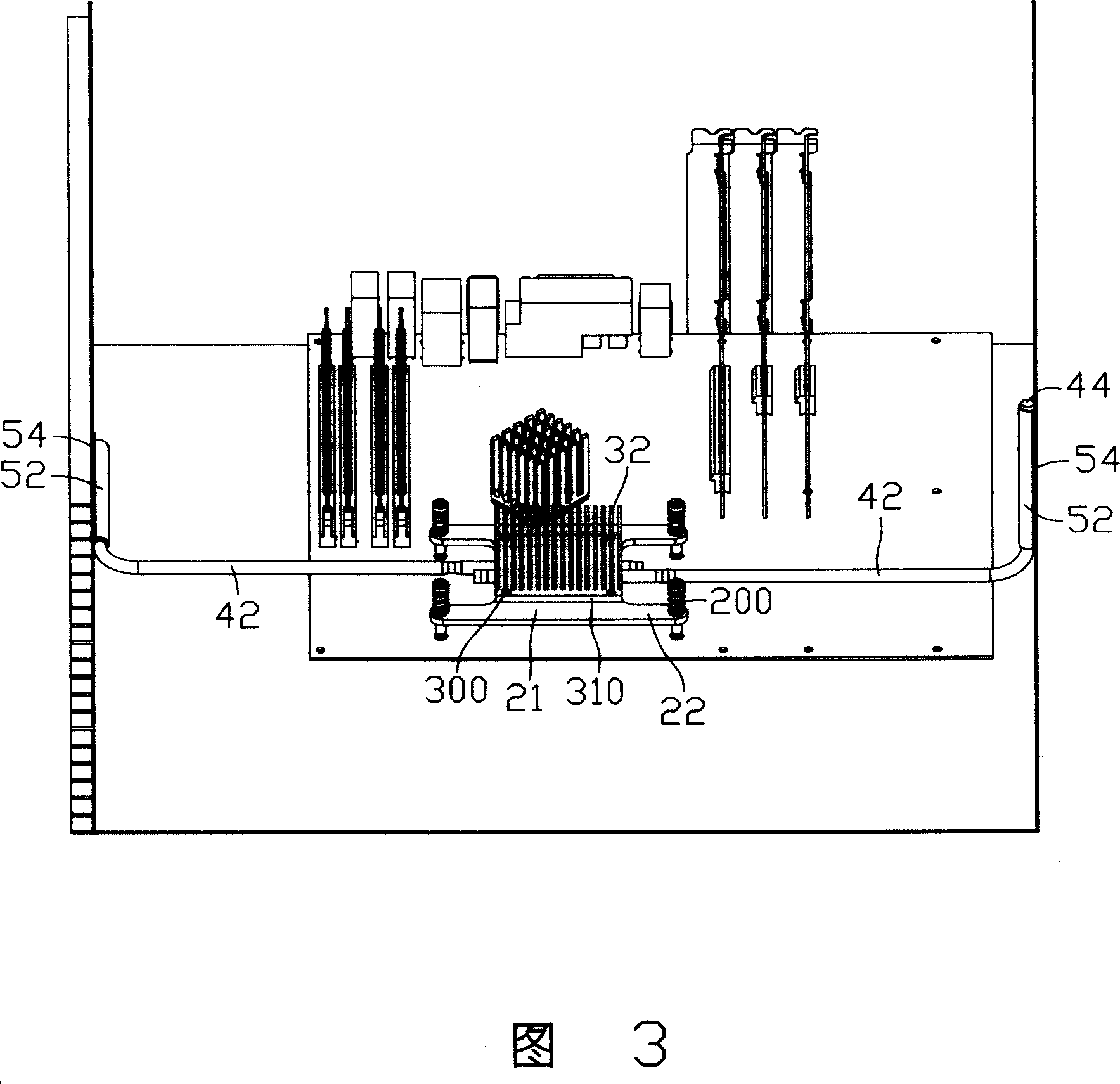

[0012] 1 to 3 show a heat sink in a preferred embodiment of the present invention, the heat sink is used to dissipate the heat generated by the central processing unit (not shown) installed on the motherboard 10, the heat sink mainly includes a A base 20 in contact with the central processing unit, a heat sink 30 mounted on the base 20, two heat pipes 40 with one end interposed between the base 20 and the heat sink 30, and the other ends of the heat pipes 40 being connected to the chassis wall respectively Two connectors 50 on the board.

[0013] The base 20 is generally made of materials with good thermal conductivity such as copper and aluminum, and has a roughly rectangular body 21 whose bottom surface is in contact with the top surface of the CPU to absorb the heat generated therefrom. The four corners of the main body 21 of the base 20 protrude outward respectively with a lug 22 , and each lug 22 is provided with a perforation (not labeled), and the perforation can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com