Heat radiator

A heat dissipation device and heat dissipation fin technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problem of increasing the total effective heat dissipation area of heat dissipation devices, small system space, and limiting the effective heat dissipation area of heat dissipation devices, etc. problem, to achieve the effect of increasing the total effective heat dissipation area and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

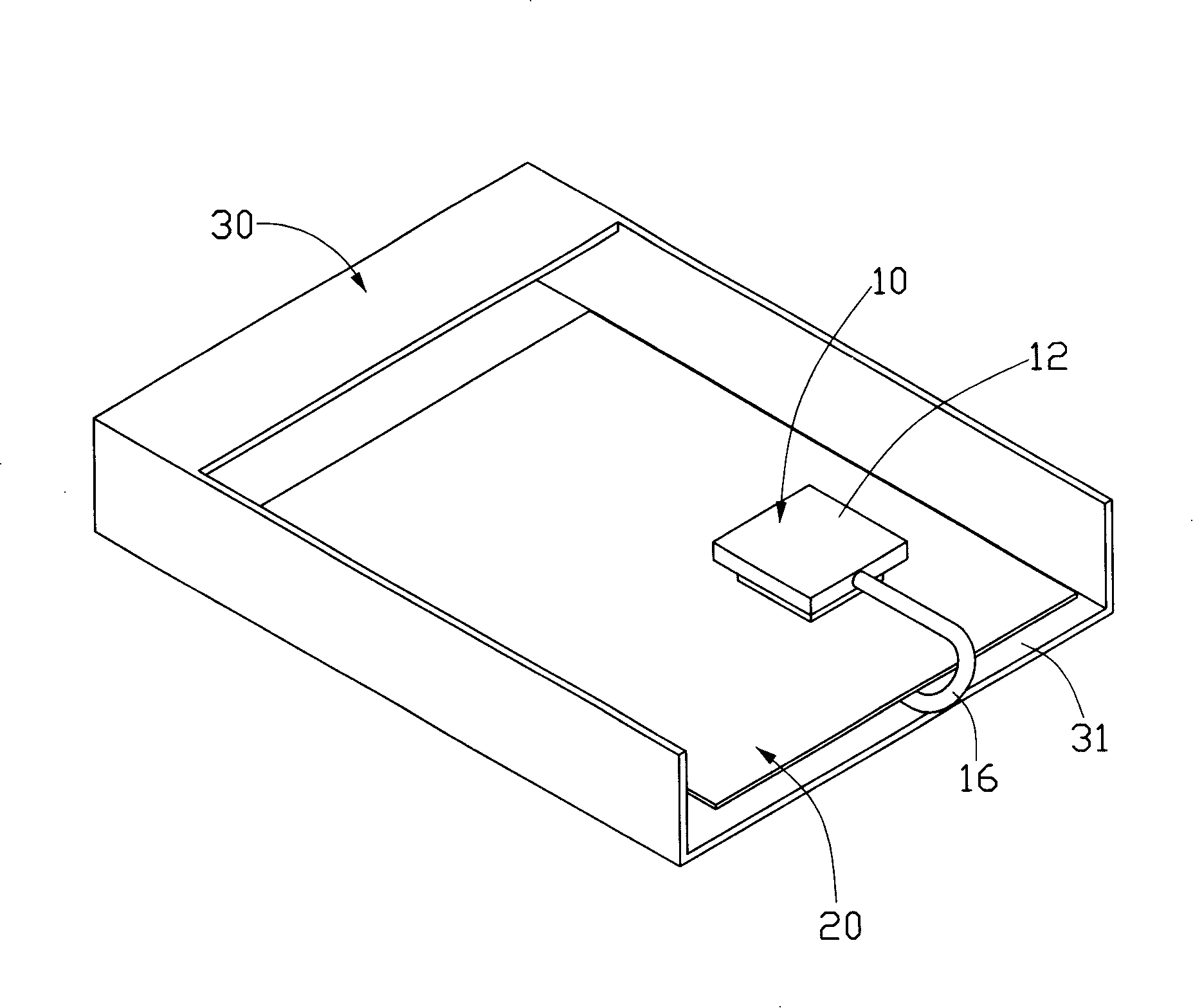

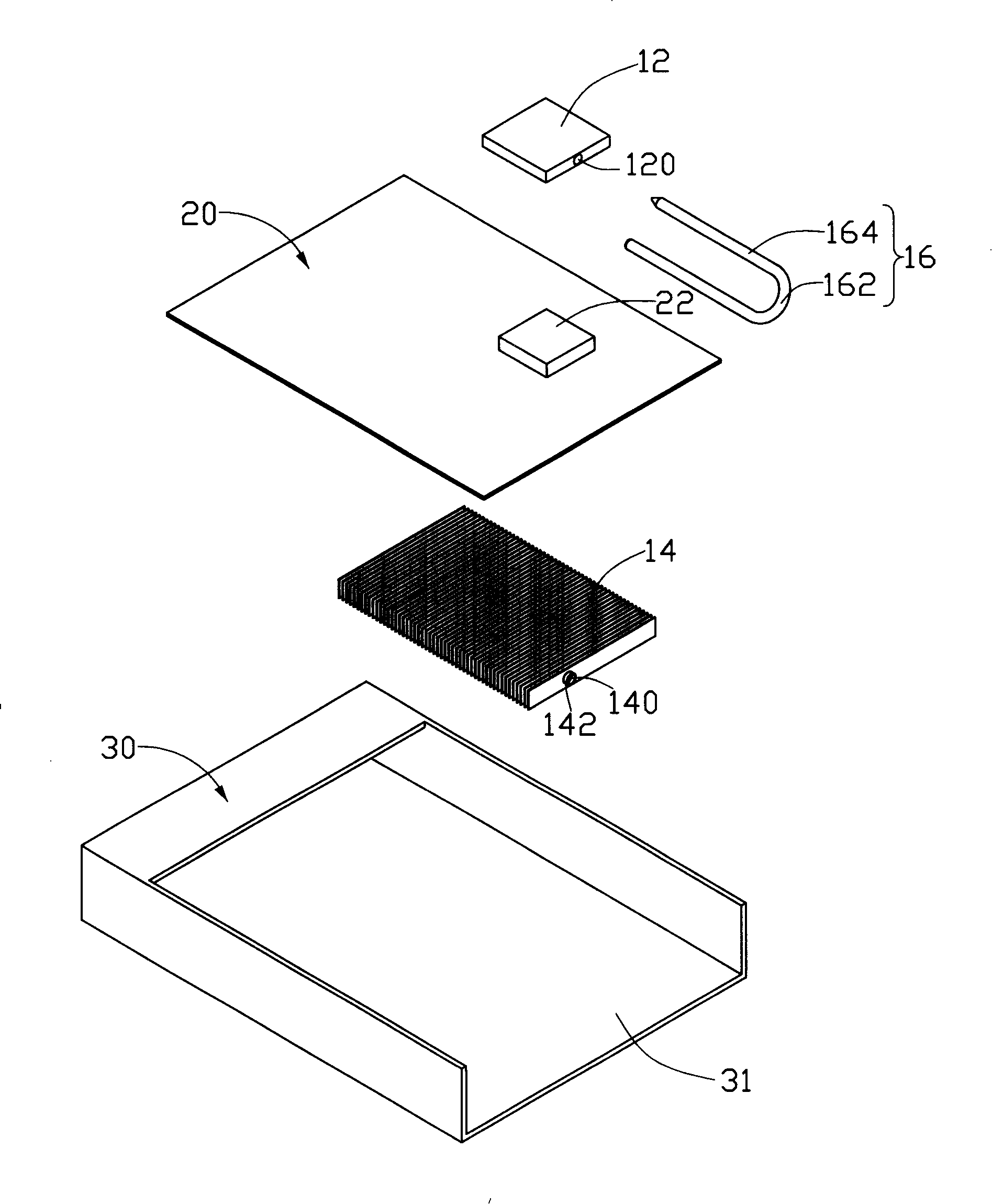

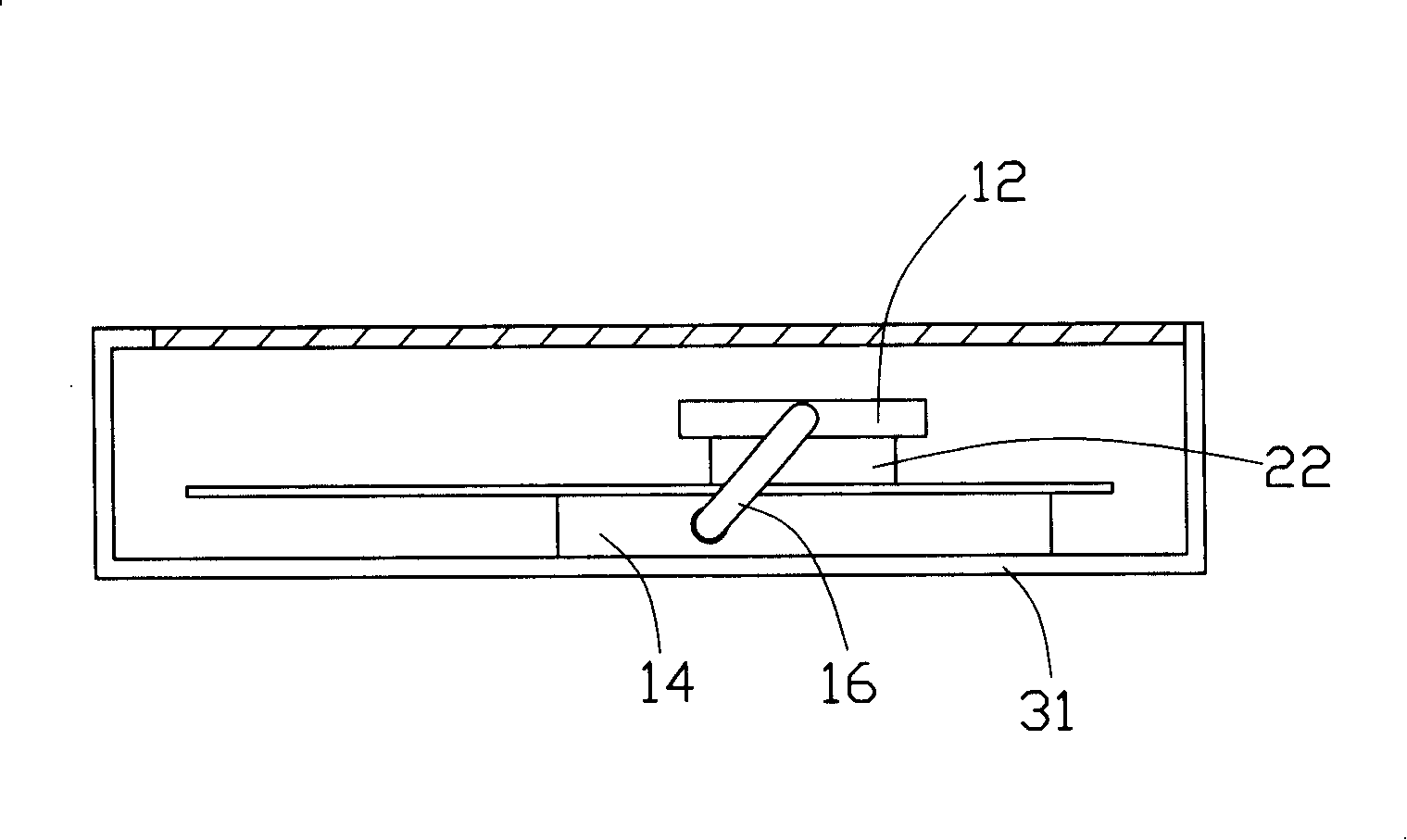

[0011] Figure 1 to Figure 3 A heat sink 10 in a preferred embodiment of the present invention is shown. The heat sink 10 is used to dissipate the electronic components mounted on the front of the circuit board 20. In this embodiment, a central processing unit 22 is used. The circuit board 20 Installed in a housing such as a computer case 30, the heat dissipating device 10 mainly includes a heat-conducting plate 12 in contact with the top surface of the central processing unit 22, a plurality of heat-dissipating fins 14 arranged in parallel on the back of the circuit board 20, and the heat-conducting plate 12 and a heat pipe 16 connecting these radiating fins 14 together.

[0012] The case 30 is made of a metal material with good thermal conductivity and is approximately a rectangular parallelepiped. The case 30 has a bottom plate 31. The circuit board 20 is mounted on the bottom plate 31.

[0013] The heat-conducting plate 12 is generally made of materials with good heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com