Heating radiator

A technology of radiators and radiators, applied in the field of radiators, can solve the problems of unable to retain the shape of cast iron radiators, beautiful appearance design, bulky cast iron radiators, high pollution, etc., to achieve beautiful products, light weight, and high heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

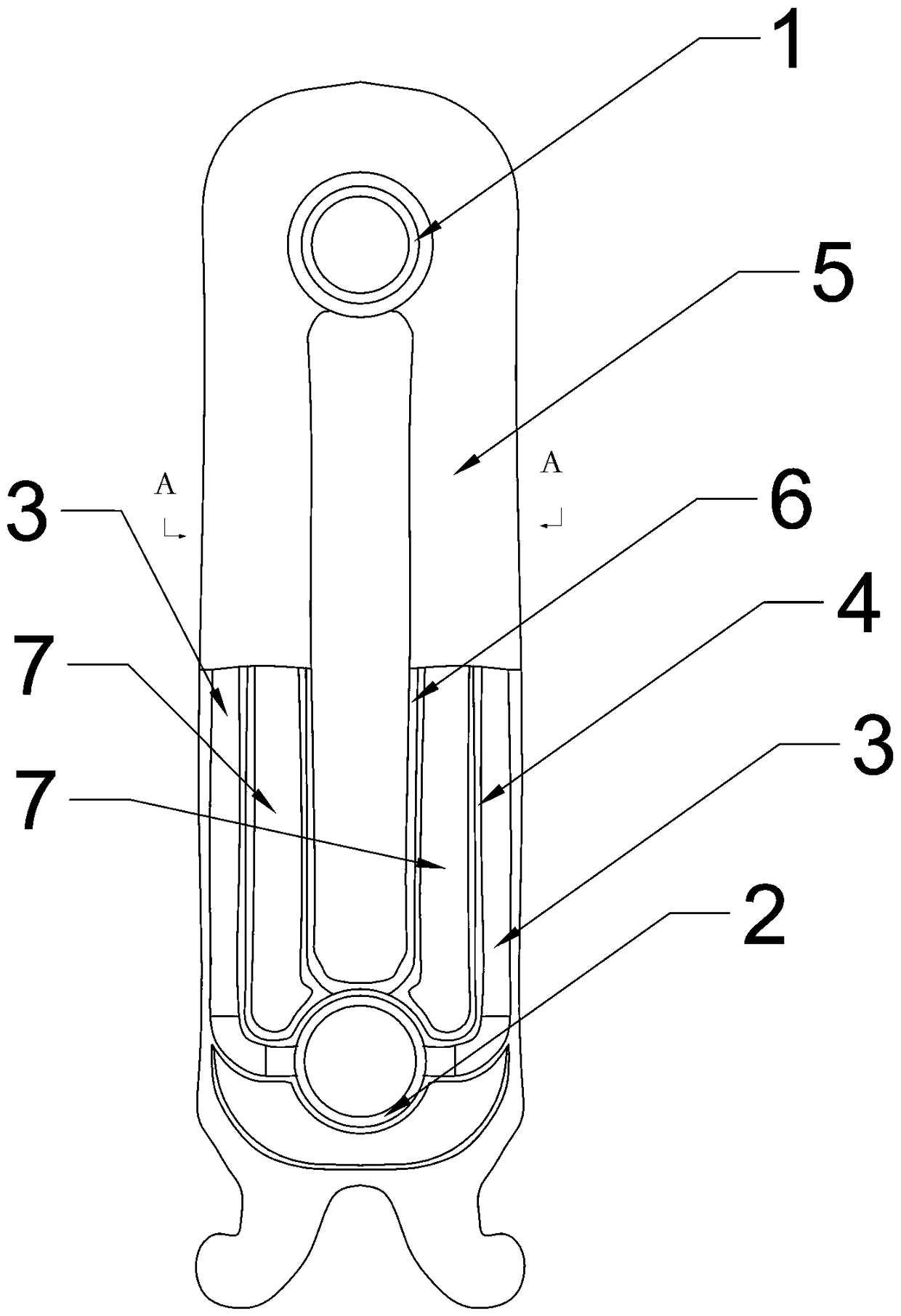

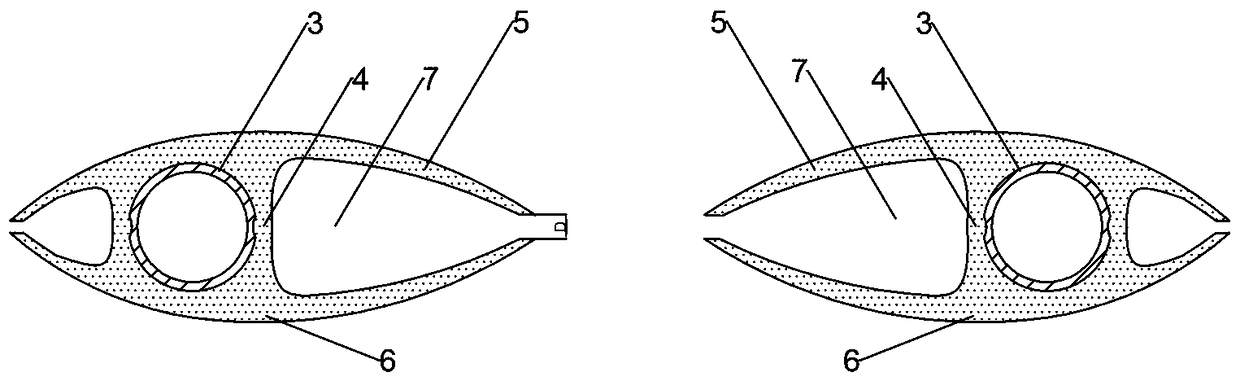

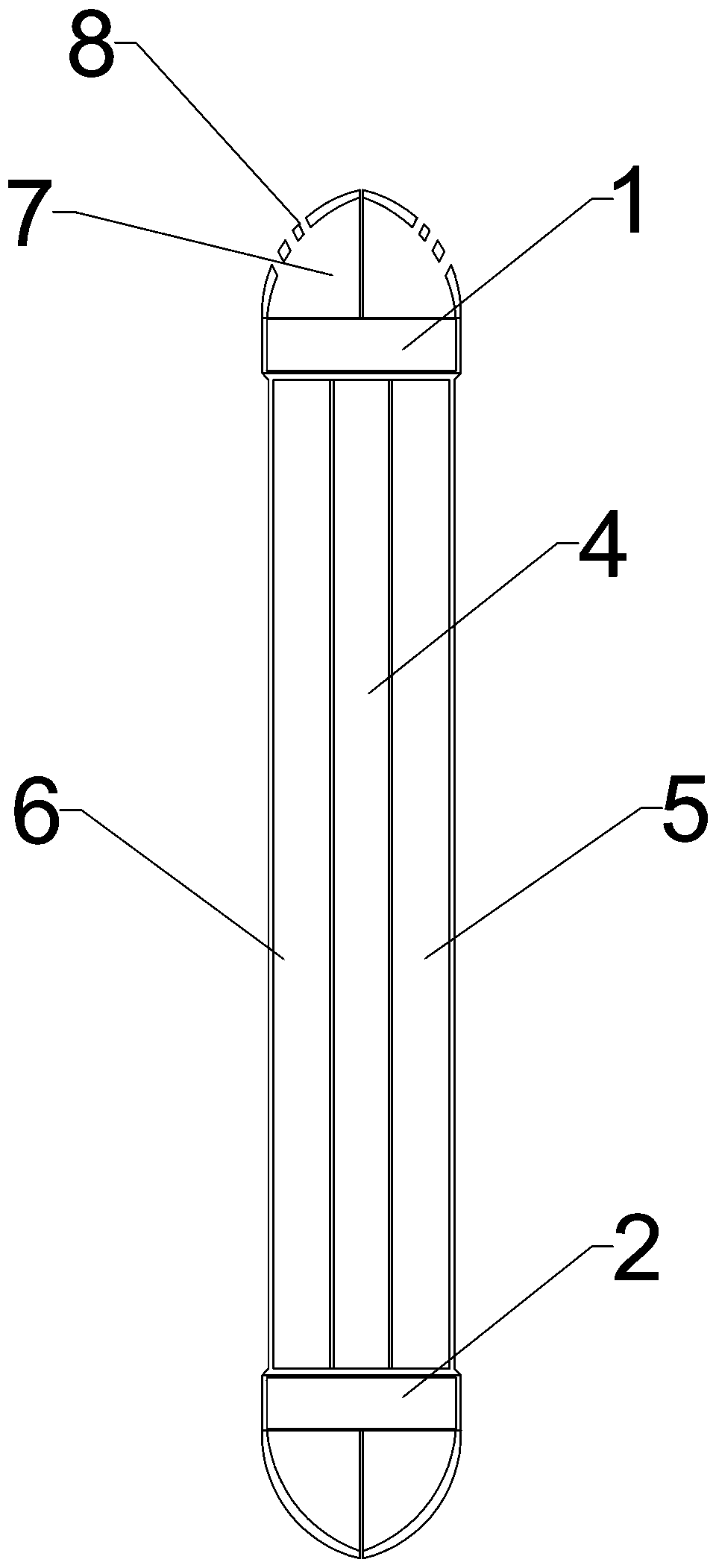

[0030] like figure 1 As shown, the radiator of the present embodiment includes a water body and a cooling fin covered on the water body; the water body includes a water inlet pipe 1, an outlet pipe 2 and a water guide pipe 3; It communicates with the water outlet pipe 2; the heat sink includes a coating layer 4, a front cooling fin 5 and a rear cooling fin 6; the coating layer 4 is coated on the water body, and the front cooling fin 5 and the rear cooling fin 6 are all from the The cladding layer 4 is extended; the front cooling fins 5 and the rear cooling fins 6 are oppositely arranged to form a semi-closed cooling cavity 7 . Aqueduct 3 is two or more than two. There are preferably two water conduits 3 . In this embodiment, the diameter of the water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com