Vessel cap and system for manufacturing the same

A container cap and container technology, applied in the direction of closing, packaging, capping, etc., can solve the problems of sanitation, inconvenient use, etc., and achieve the effects of preventing environmental pollution, shortening the preparation process, and saving preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

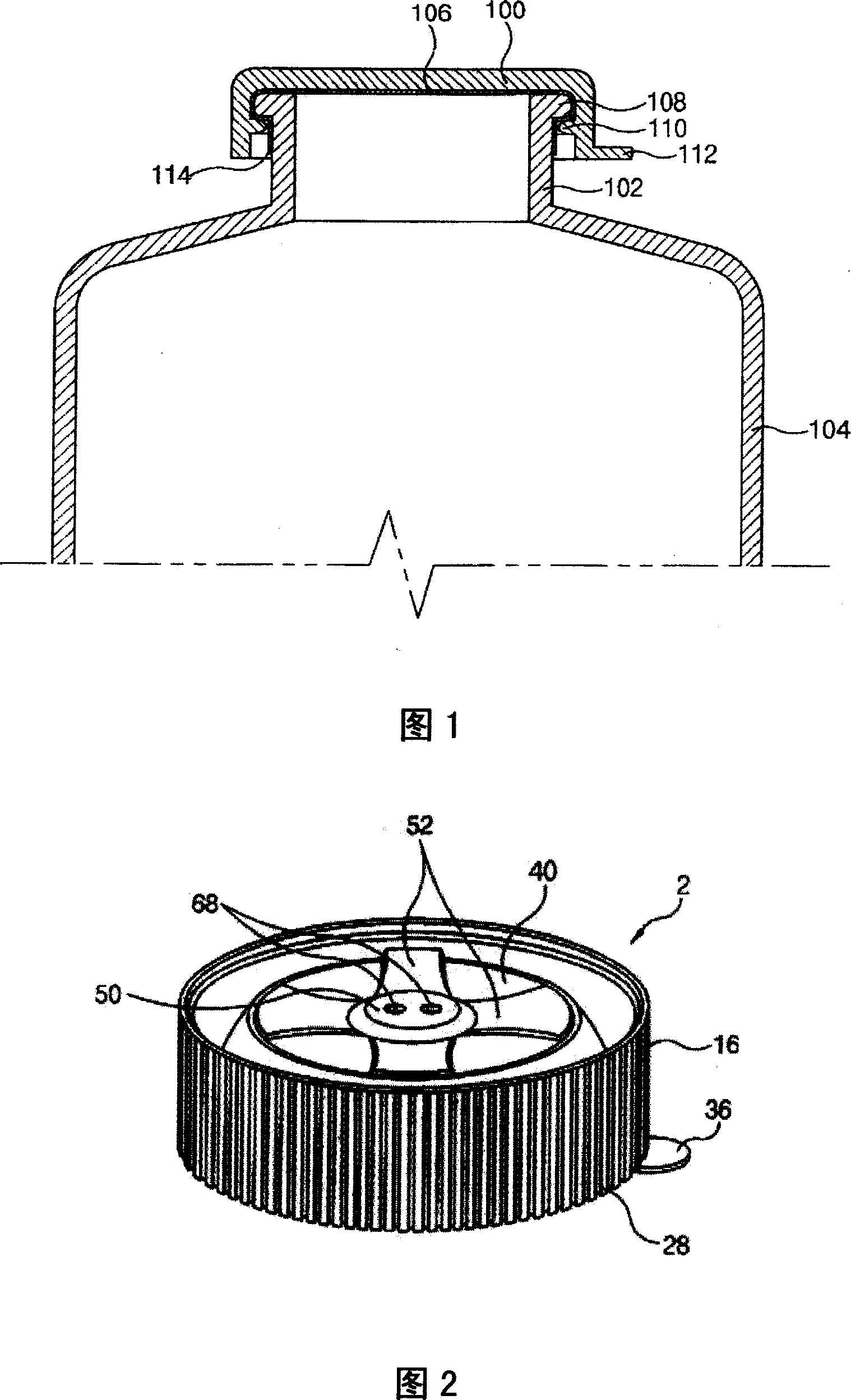

[0173] The manufacturing apparatus of the container cap according to the third embodiment of the present invention, as an injection molding apparatus for injection molding, includes the following structure: a first core 202 formed with an injection port 200 through which plastic melt is injected and positioned at the upper part be configured on the lower side of the above-mentioned first core 202, and form the second core 206 for forming the cavity 204 of the container cap with the first core 202; be inserted into the central position of the second core 206 to form the container cap The third core 208 of the card protrusion 178; the stripper plate (stripper plate) 210 that separates the container cap configured and formed between the first core 202 and the second core 204.

[0174] A cavity 204 for injecting the plastic melt is formed between the first core 202 and the second core 206 as in the container cap described above.

[0175] The central position of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com