Drawing-plate mechanism for pressure filter and its operation

A filter press and plate pulling technology, which is applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as two-way decoupling of the pull plate hook, left and right shaking, and synchronization of movement speed, and achieve reliable manufacturing costs. Hook is convenient and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

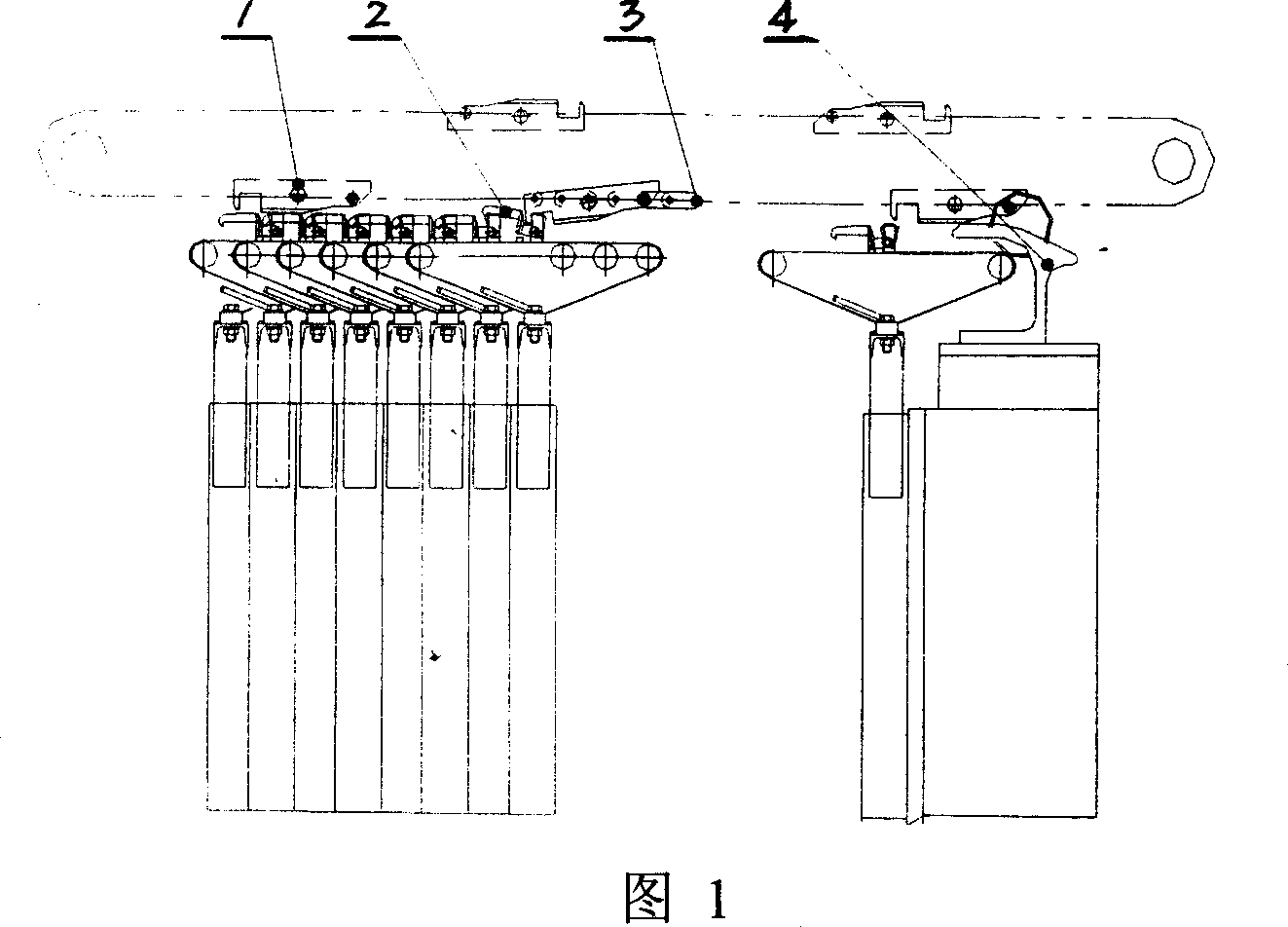

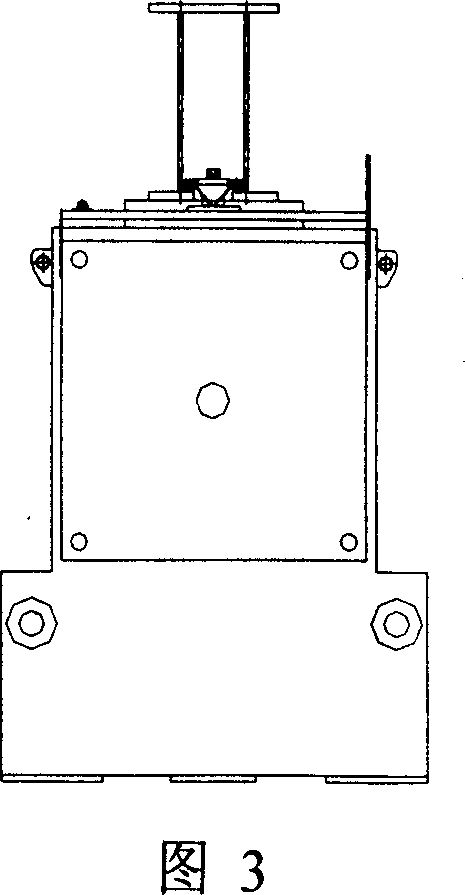

[0014] Embodiment 1: with reference to accompanying drawing 1~6. The pull plate mechanism of the filter press, the claw tongue 2 is a lever structure and is processed and manufactured by the existing technology. The claw tongue 2 is located on the top of the filter plate, and the claw tongue 2 is connected with the claw tongue on the top of the adjacent filter plate. The pull tongue located in the suspension beam There are many pull plate hooks 1 on the plate chain 3 and cooperate with the power arm of the claw tongue 2, and the claw tongue 2 is made of a power arm, a fulcrum and a resistance arm and the head of the resistance arm is a hook structure. The decoupling frame 4 is located below the side of the pull plate chain 3 and there are many pull plate hooks 1 on the pull plate chain 3. The resistance arm of the pull plate hook 1 is lifted by the release frame when it passes through the release frame 4. The upper end of the release frame 4 is curved. shape. The pull plate h...

Embodiment 2

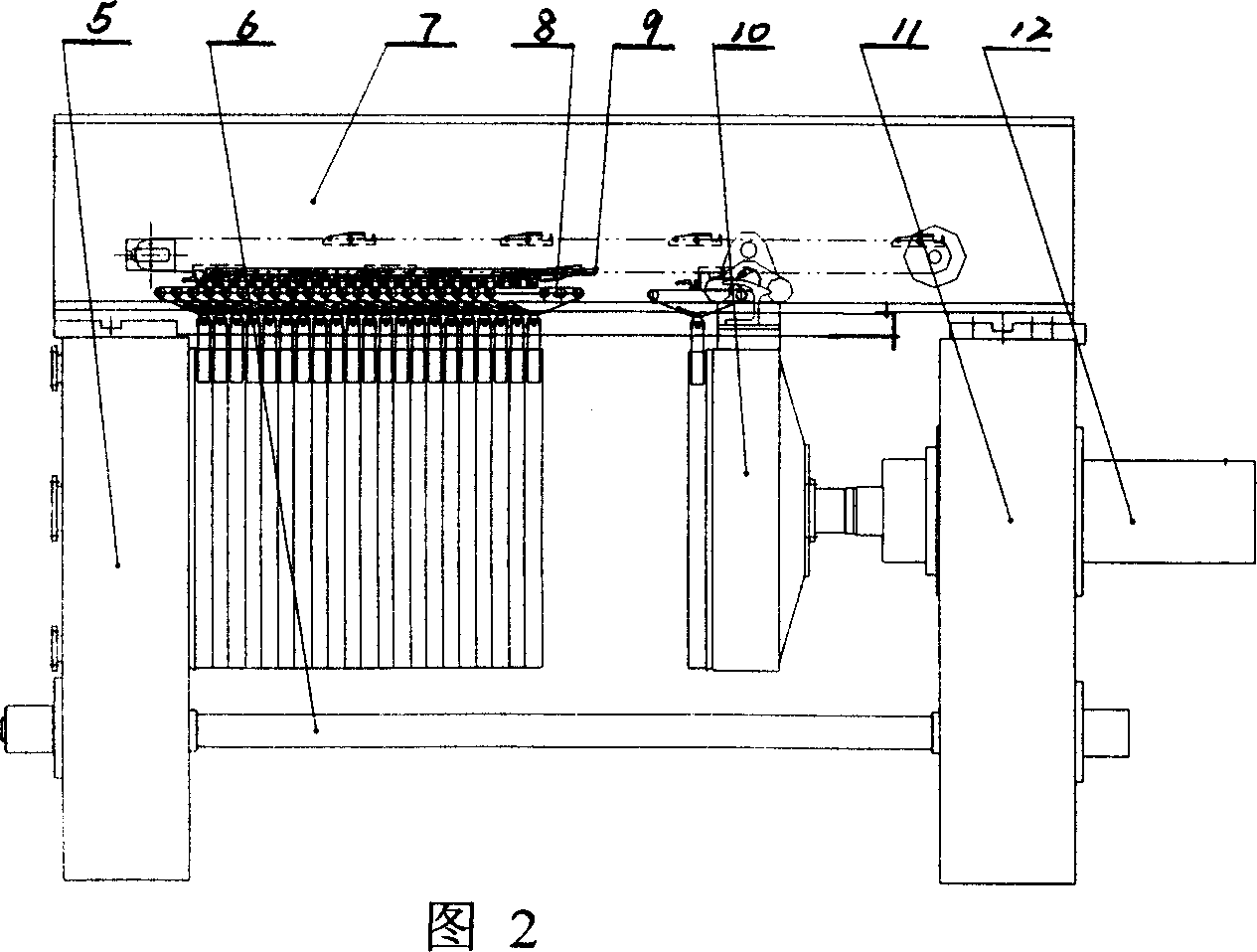

[0017] Embodiment 2: On the basis of Embodiment 1, the working method of the plate pulling mechanism of the filter press, each claw tongue on the filter plate is connected with the claw tongue on the upper end of the adjacent filter plate respectively and forms a suspended automatic Lock the filter plate assembly, there are multiple pull plate hooks 9 on the pull plate chain 8 located in the suspension beam and cooperate with the power arm of the claw tongue, the motor drives the pull plate chain to run counterclockwise, the pull plate hook is on the suspension of the filter plate Slide on the mechanism, when it slides to the last filter plate, it crosses the claw tongue on the suspension mechanism, the pull plate hook falls by its own weight, and meshes with the claw tongue on the suspension mechanism, the power arm of the claw tongue is pressed down by the pull plate hook, The claw hook of the claw tongue is lifted, and the self-locking of the filter plate and the filter plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com