Self-upright pressure-differential balance valve and its production

A self-operated differential pressure and balance valve technology, applied in balance valves, safety valves, valve devices, etc., can solve the problems of high relative failure rate, many components, complex structure, etc., and achieve the effect of easy installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

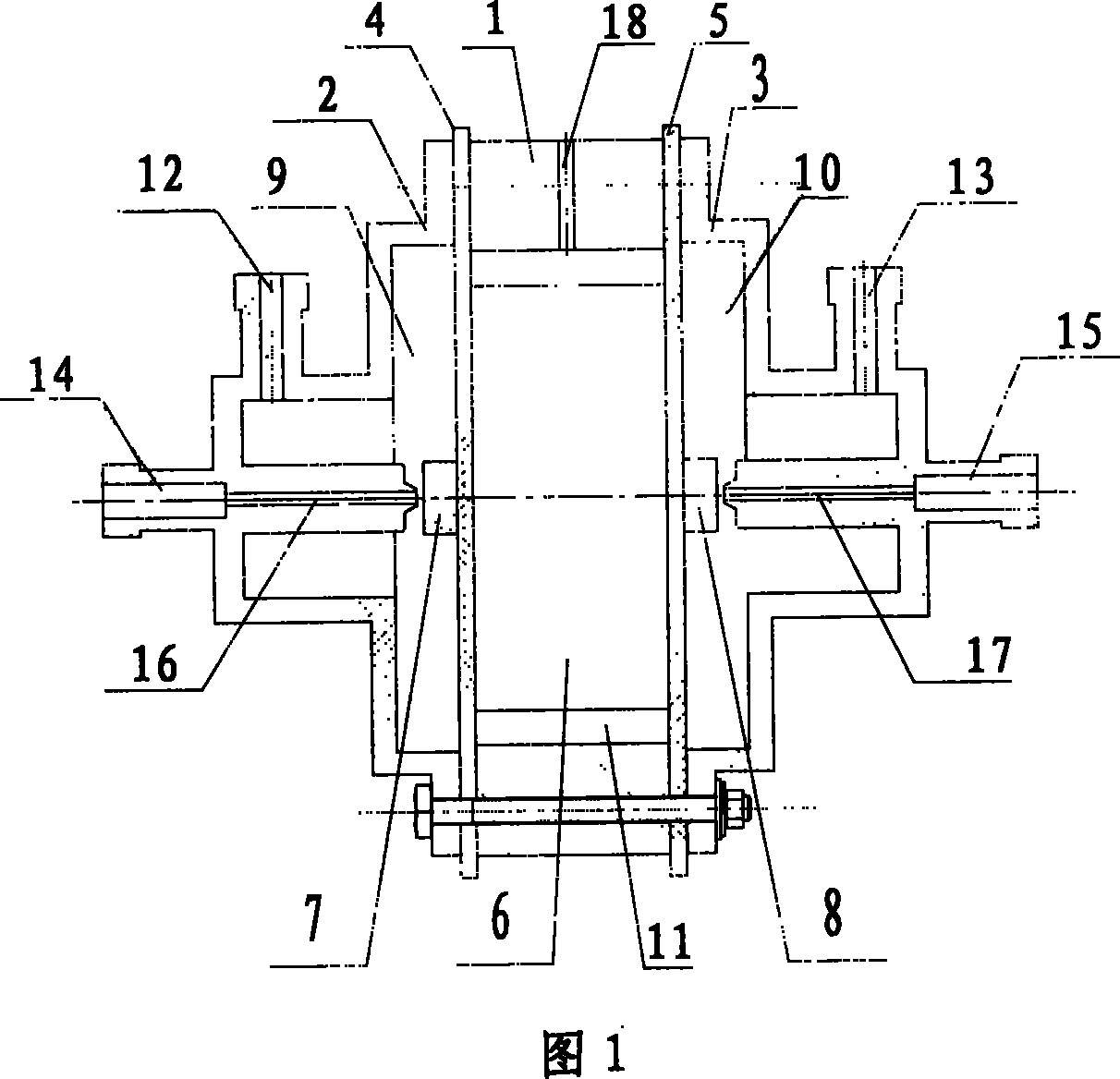

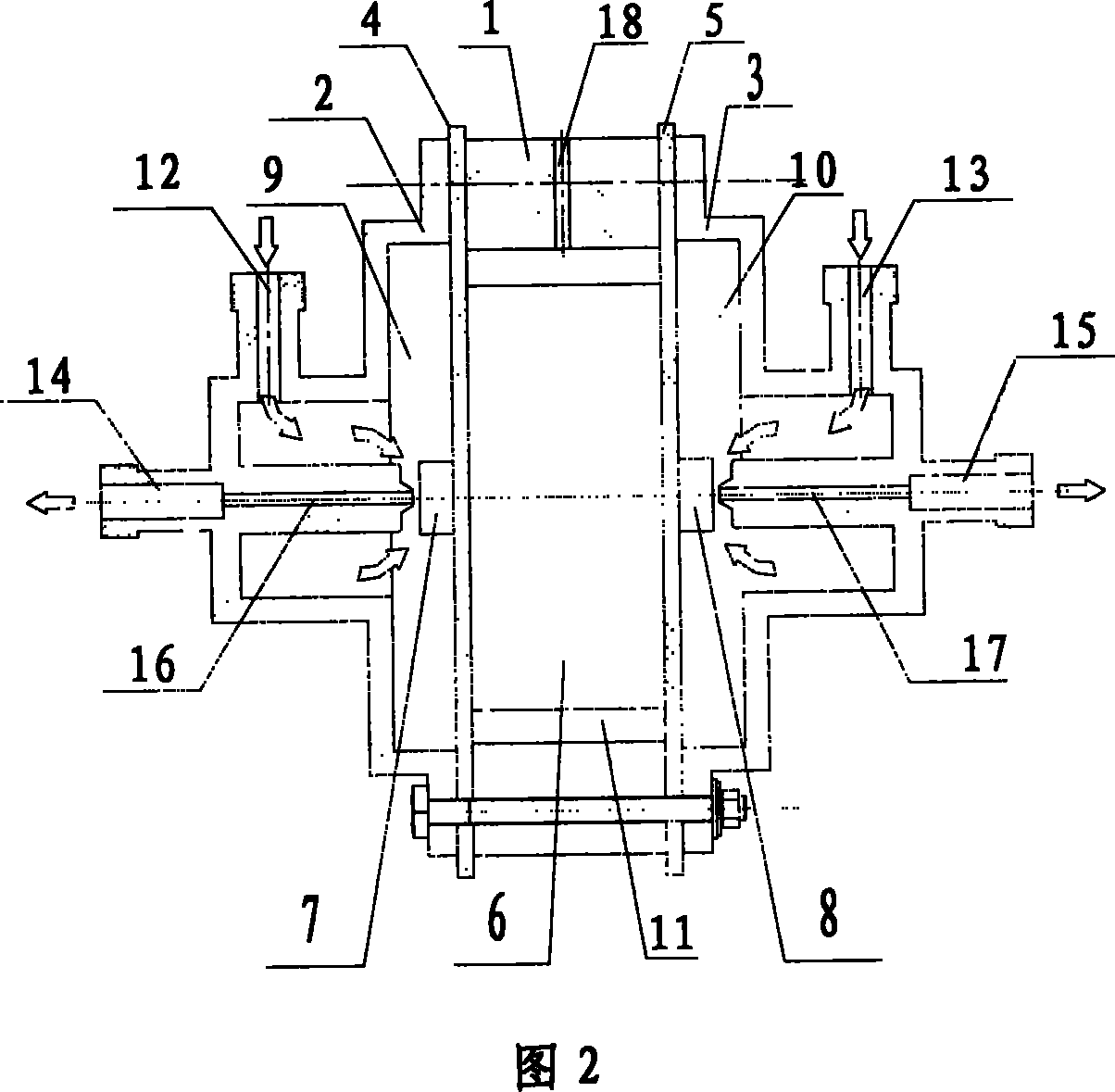

[0016] Embodiments of the present invention and their effects will be further described below in conjunction with the accompanying drawings. Referring to the accompanying drawings 1 and 2, the self-operated differential pressure balancing valve includes a valve body 1 and valve seats 2 and 3 respectively located on both sides of the valve body. Diaphragms 4 and 5 are respectively installed between the two valve bodies and valve seats.

[0017] Valve body 1, valve seats 2, 3 and valve seats 4, 5 are assembled to form two end air chambers 9, 10 and a middle air chamber 11 respectively.

[0018] A movable block 6 is arranged in the middle air chamber 11 and is connected with the diaphragms 4 and 5 .

[0019] The two end air chambers 9, 10 are provided with valve cores 7, 8, which are respectively connected with the diaphragms 4, 5 and can move together with the diaphragms.

[0020] The valve seats 2, 3 are respectively provided with gas inlets 12, 13, gas outlets 14, 15 and gas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap