Low-noise decelerator for washing machine

A technology of reducer and washing machine, applied in other washing machines, washing devices, mechanical equipment, etc., can solve the problems of high noise, poor transmission stability, large transmission ratio, etc., to achieve noise reduction, strong and durable components, and good shock and vibration resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

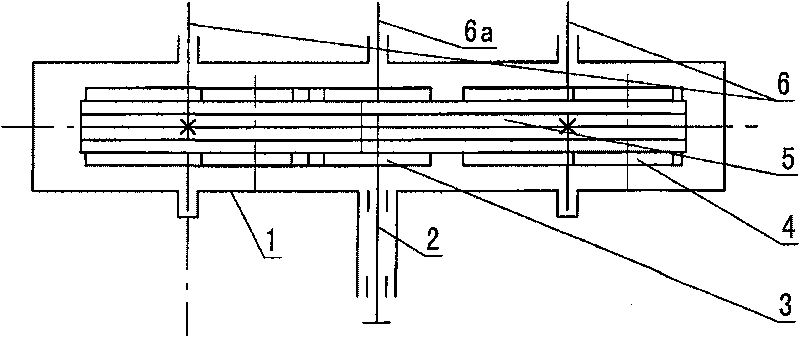

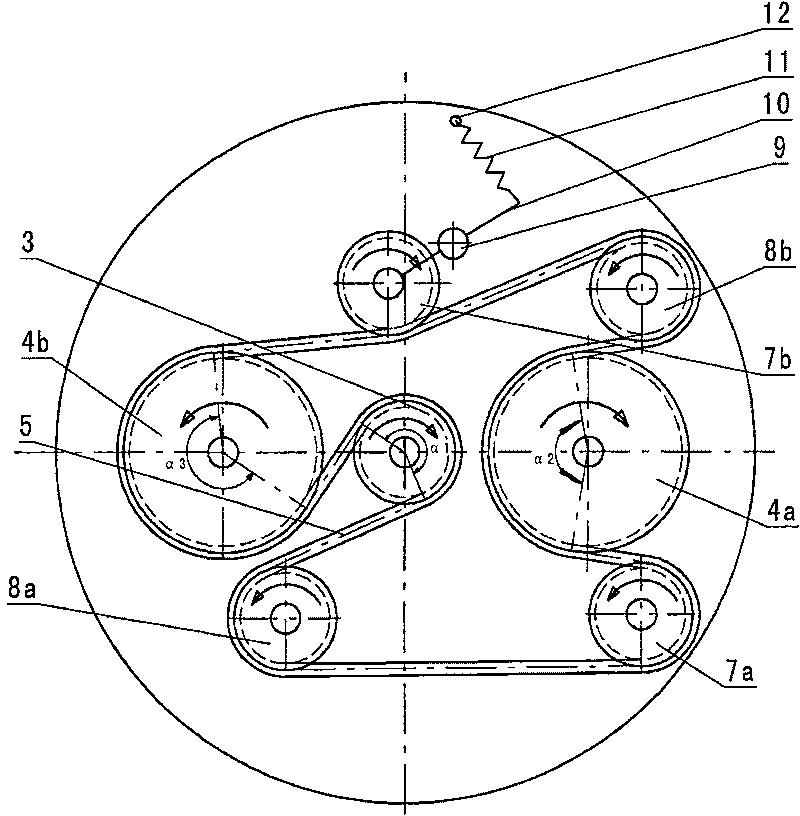

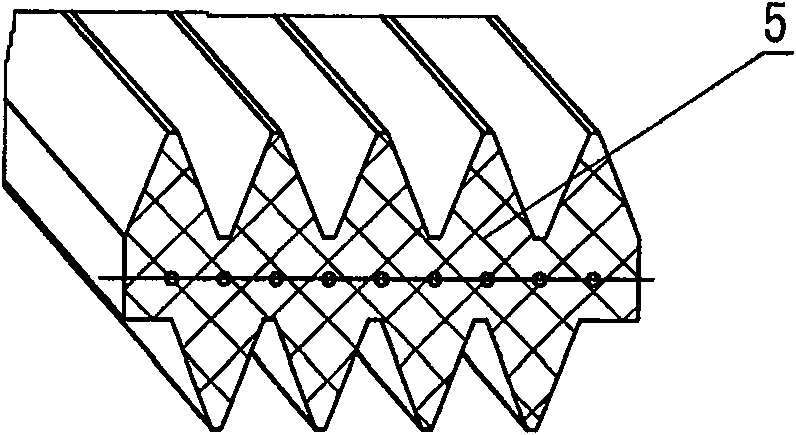

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 , Figure 1A , is the low-noise washing machine speed reducer of the present invention, and its deceleration transmission mechanism is a fixed shaft transmission type, which is mainly composed of a housing 1, an input shaft 2, a driving wheel 3, driven wheels 4a, 4b, intermediate wheels 8a, 8b, fixed tension Wheel 7a, automatic tensioner 7b and output shafts 6, 6a are connected together by double-sided V-ribbed belt 5, driving wheel 3 is fixed on input shaft 2, driven wheels 4a, 4b are fixed on output shaft 6 The intermediate wheels 8a, 8b and the output shaft 6 are movably installed on the housing 1, and the driving wheel 3, the driven wheels 4a, 4b, the intermediate wheels 8a, 8b, and the tensioning wheels 7a, 7b are provided with multi-ribbed grooves 13, and the multi-ribbed A double-sided V-ribbed belt 5 is installed on the groove 13; the fixed te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com