Optical coupling system for large power laser diode array

A laser diode and optical coupling technology, applied in the field of optical coupling systems, can solve the problems of reducing coupling efficiency, astigmatism, affecting the size of the focused spot and the depth of focus, etc., to achieve the effect of overcoming astigmatism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

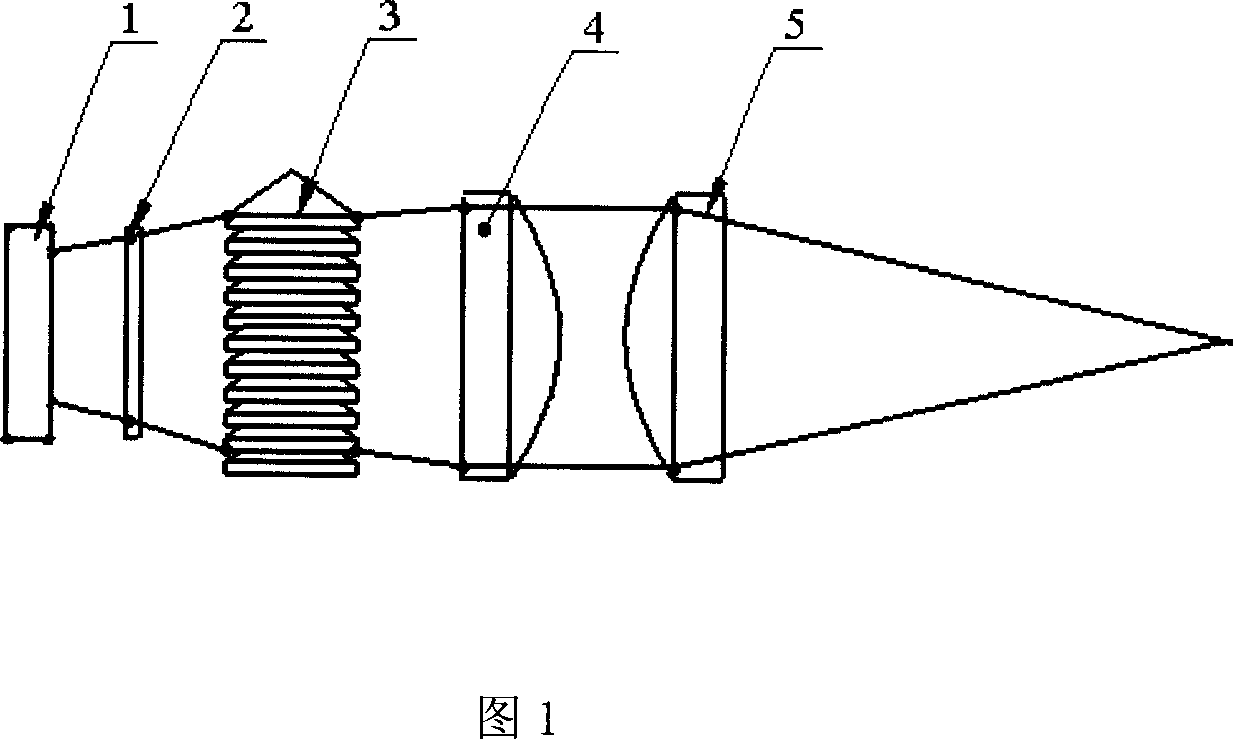

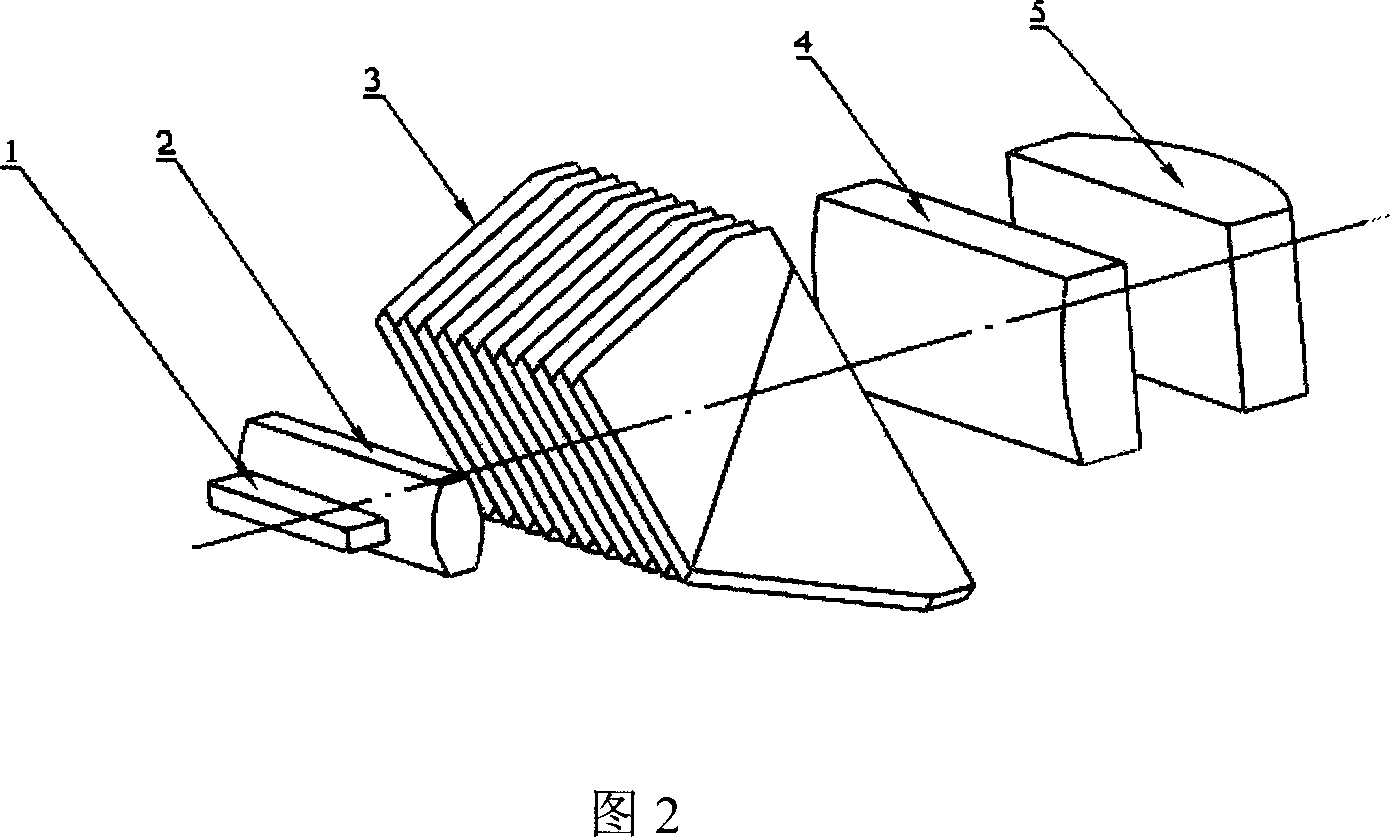

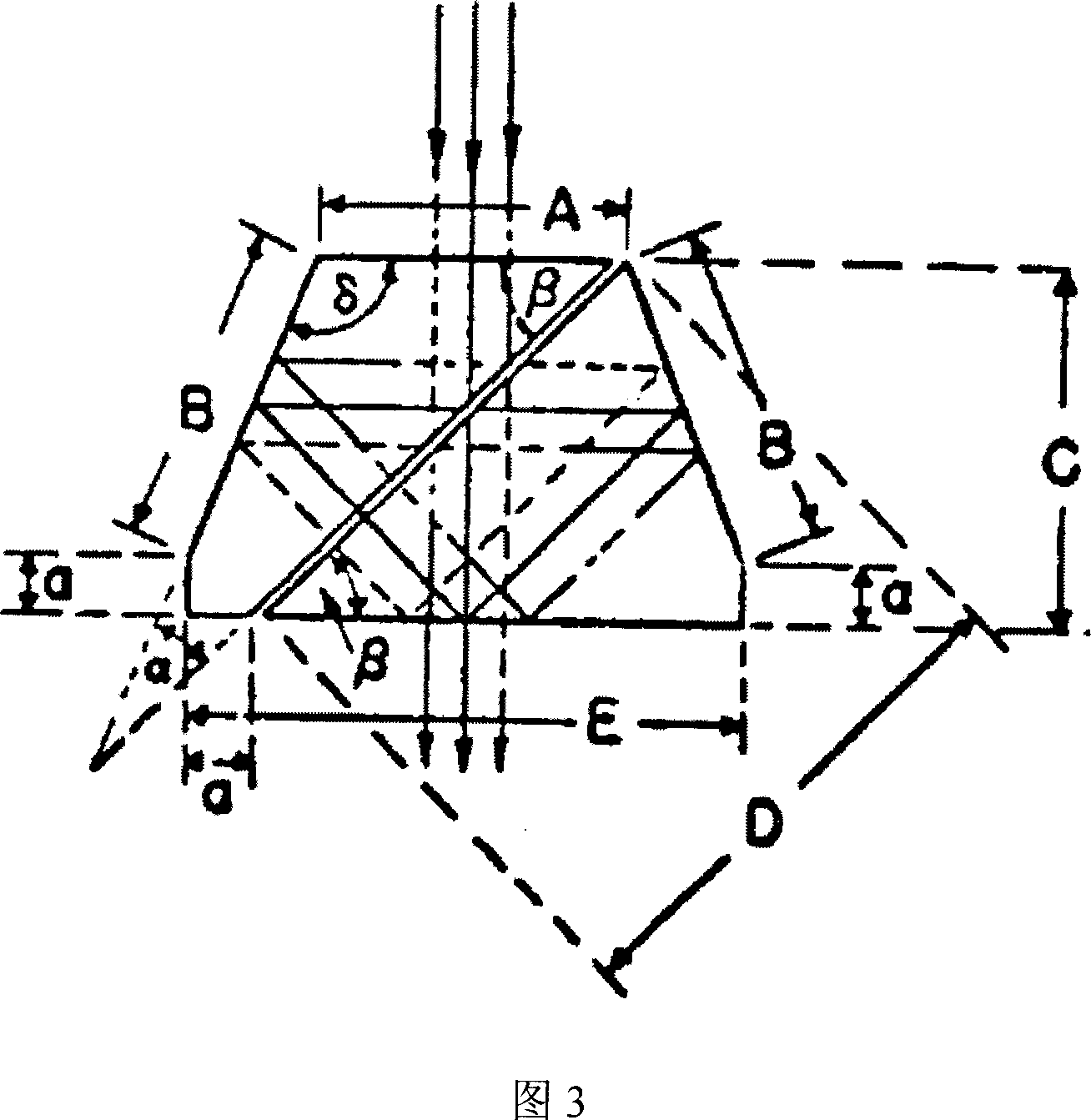

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby. Please refer to Fig. 2 first, Fig. 2 is the structural representation of the optical coupling system that the present invention is used for high-power laser diode array, as can be seen from the figure, the present invention is used for the optical coupling system of high-power laser diode array, comprises along the high-power laser diode Micro-cylindrical lens 2 arranged in sequence in the advancing direction of the light beam emitted by array 1, shaper 3, first cylindrical lens 4 and second cylindrical lens 5, it is characterized in that described shaper 3 is made of Biechan prism sheet Closely arranged Bechan prism microchip shaper, the optical axis of each Bechan prism is consistent with the direction of light beam advancement and rotated 45° around the optical axis, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com