Transmission type film test card for camera test and its usage method

A transmissive, test card technology, applied in the field of test cards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

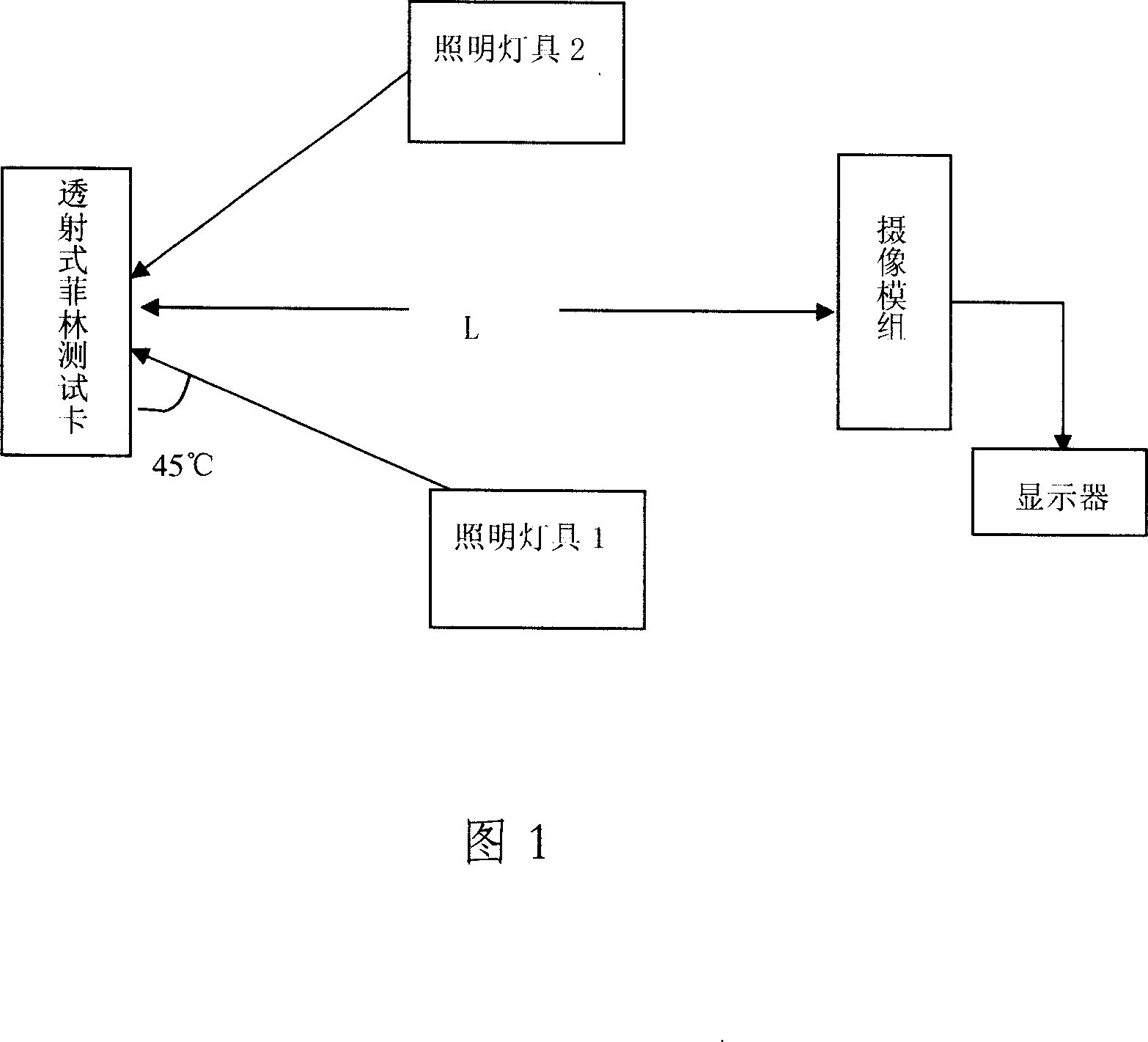

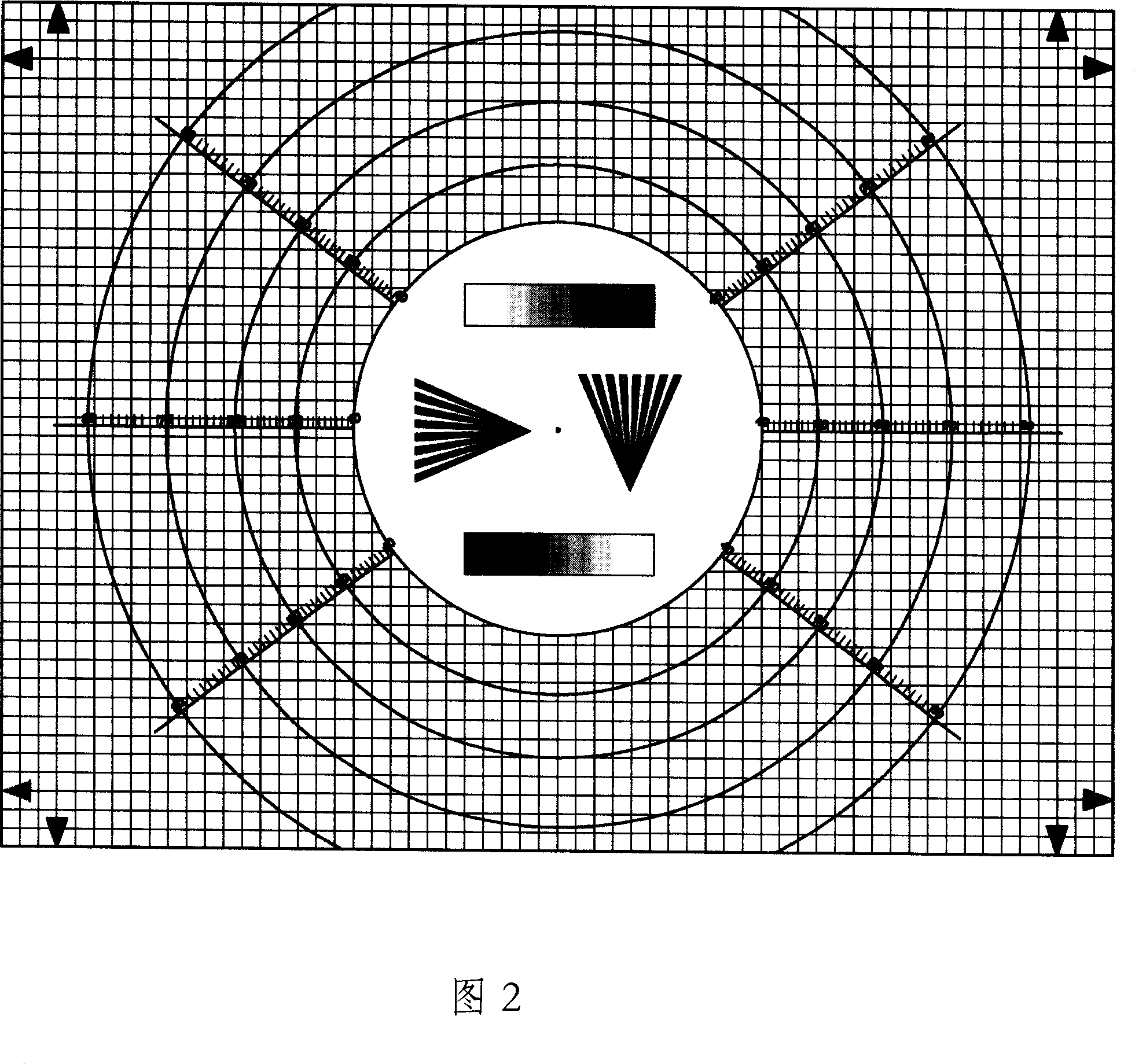

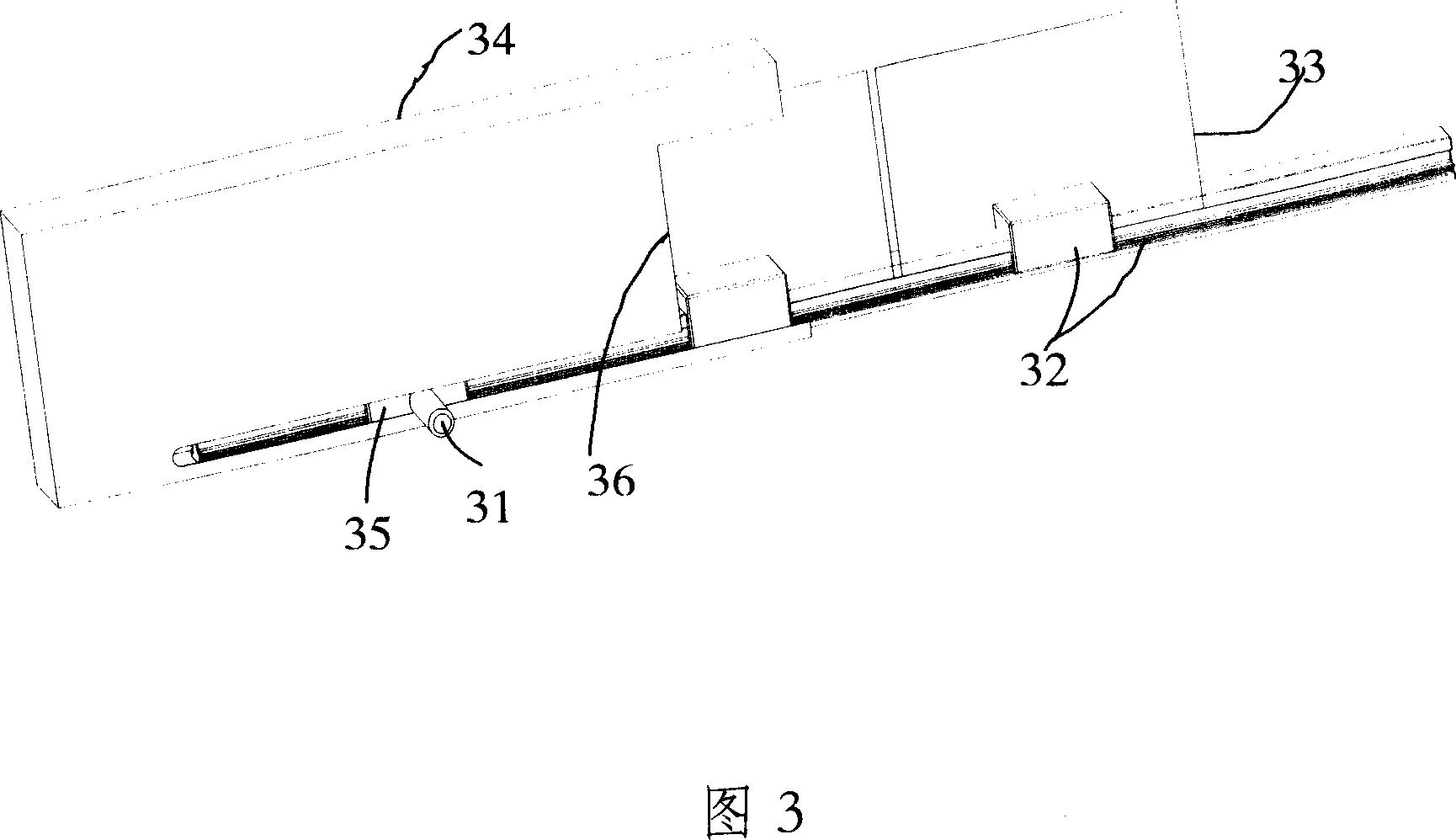

[0023] See Figure 1, Figure 2, Figure 3.

[0024] The surface pattern of the transmissive film test card in the embodiment is a grid. There are several concentric circles on the background. There are digital scales in the horizontal and diagonal directions. The center with the role of positioning point is the center of the concentric circles. Two fan-shaped line patterns for resolution detection. There is a nine-grid test grayscale bar above and below the center of the circle. The colors of the grayscale bars are arranged in reverse order. The fan-shaped line pattern and the test grayscale bar are located in the innermost circle. Inside, there is no grid pattern in the innermost circle, and there are positioning indicators on the four sides. The grid background is black straight lines criss-crossed vertically, horizontally and vertically distributed symmetrically around the central positioning point (ie, the center of the circle), and the distance between rows and columns is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com