Six degree of freedom buttjunction platform

A docking platform and degree of freedom technology, applied to workbenches, manufacturing tools, etc., can solve the problems of no work platform and the inability to realize six degrees of freedom of movement, and achieve the effects of improving stability, facilitating operation control, and assembly and disassembly maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

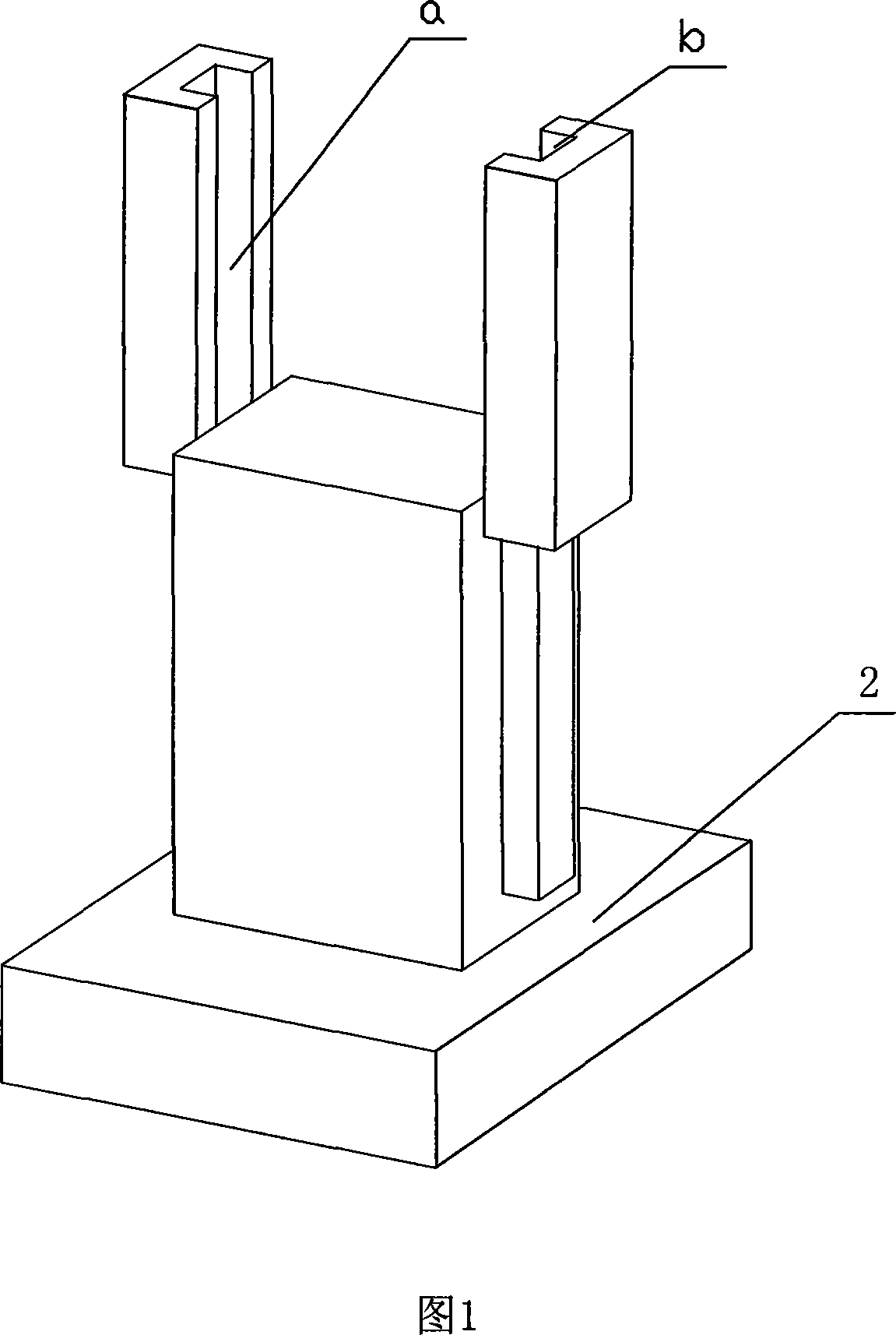

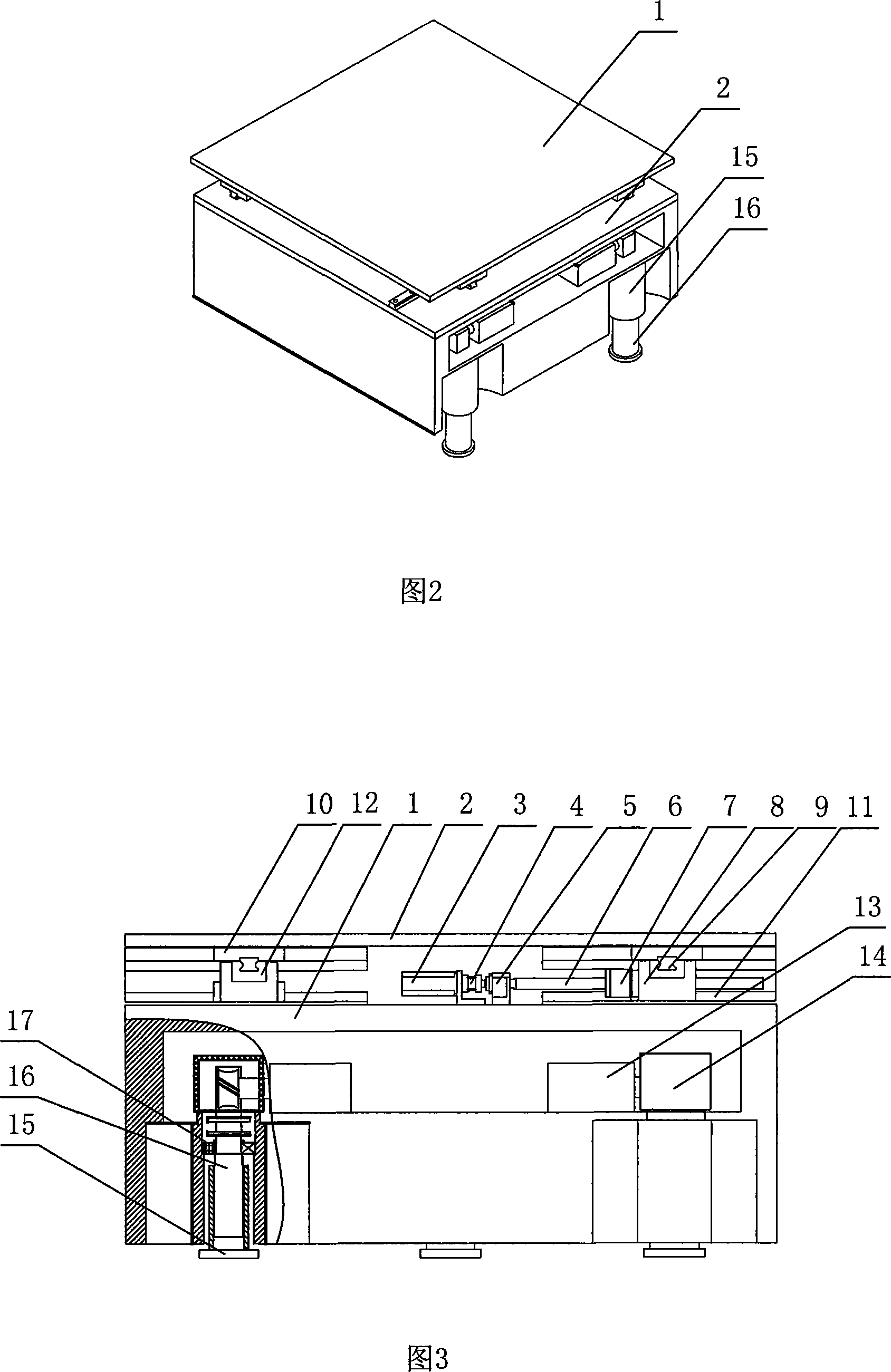

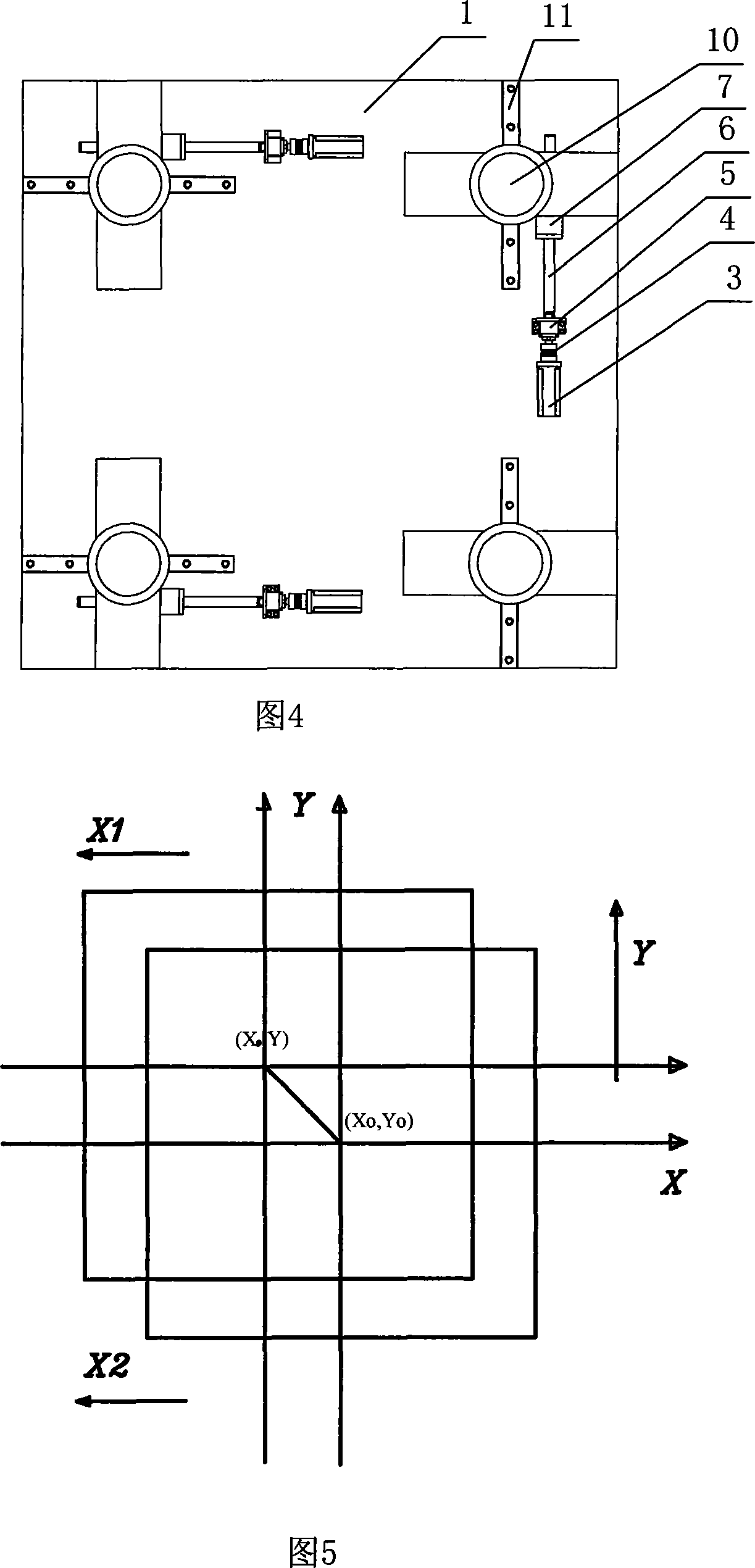

[0063] As shown in Figures 2, 3, and 4: a six-degree-of-freedom docking platform, consisting of a supporting platform 1, a working platform 2, three plane adjustment mechanisms with the same structure, a follow-up mechanism, and three vertical adjustment mechanisms with the same structure. The three plane adjustment mechanisms and one follow-up mechanism are arranged between the support platform 1 and the working platform 2, which are distributed in a square shape. Three vertical adjustment mechanisms with the same structure are installed on the support platform 1 below the plane adjustment mechanism. , They are distributed in a triangle; the plane adjustment mechanism is composed of a horizontal motor 3, a coupling 4, a screw rod 6 and 7 pairs of nuts, a movable sliding seat 8, a sliding block 9 and a bearing 10. The horizontal motor 3 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com