Coke oven masonry construction method employing upright line rod

A technology for coke ovens and wire poles, which is applied in coke oven bricklaying operations, etc. It can solve the problems that the uniformity of the thickness of each layer of brick joints is difficult to control, it is difficult to find problems, and the geometric size error of masonry is large, so that it is convenient to check the size error Reliable, reduce over-dependence, reduce the effect of geometric size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

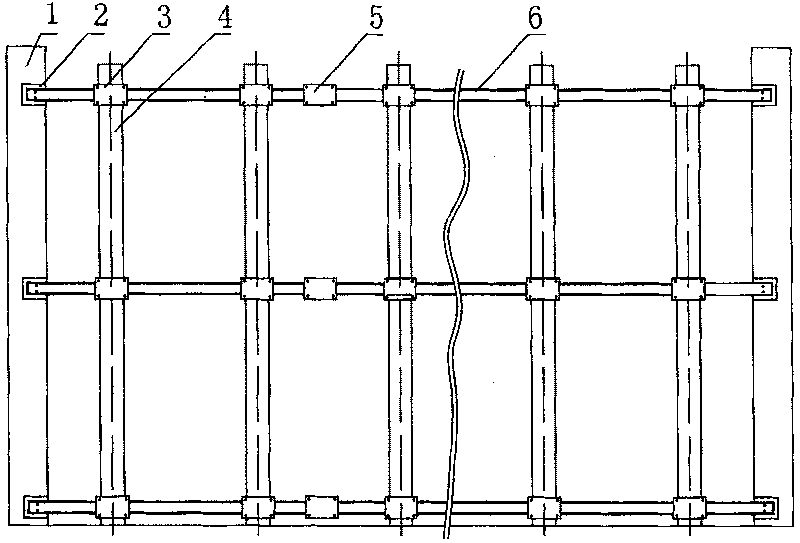

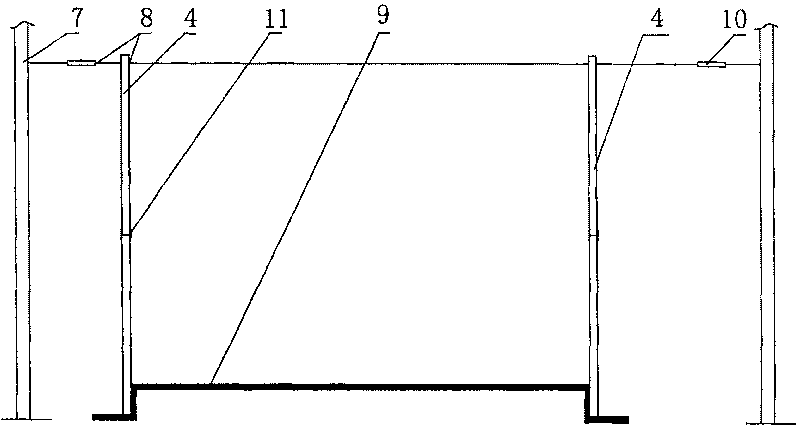

Image

Examples

Embodiment Construction

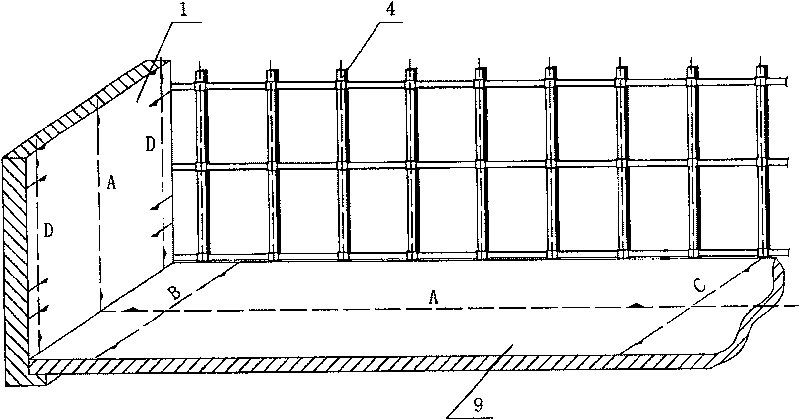

[0015] Through the following description of the embodiments of the present invention and the accompanying drawings, the purpose, specific method features and advantages of the present invention can be further understood.

[0016] see image 3 , a kind of coke oven masonry method with upright pole, its steps are:

[0017] In the first step, before the concrete is poured on the coke oven foundation platform 9, permanent stakes and six reference points are pre-embedded on both sides of the coke oven coke by civil engineering, and the reference points are pre-embedded on the resistance walls 1 on both sides; On the four corners of the inner surface of the front, angle steels are respectively welded in the furnace, and the center line B of the combustion chamber at the end of the furnace is cast on the angle steels from the foundation platform 9 .

[0018] In the second step, the longitudinal center line A of the coke oven is based on the center reference point of the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com