Micro-driver and magnetic head tabs assembly and magnetic disk drive unit

A micro-driver and magnetic head technology, applied in the direction of maintaining the alignment of the head frame, the configuration/installation of the recording head, etc., can solve the problem of inability to achieve large magnetic head position adjustment, difficulty in ensuring the assembly accuracy of the magnetic head and/or piezoelectric element, and complicated installation process and other problems, to achieve the effect of reducing assembly cost, increasing the position adjustment range, and having a large position adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Several embodiments of the microactuator of the present invention are now described. It should be noted that the microdrive can be applied to any disk drive device having a microdrive, and is not limited to the specific structure shown in the drawings. That is, the present invention is applicable to any suitable microdrive-containing device in any field.

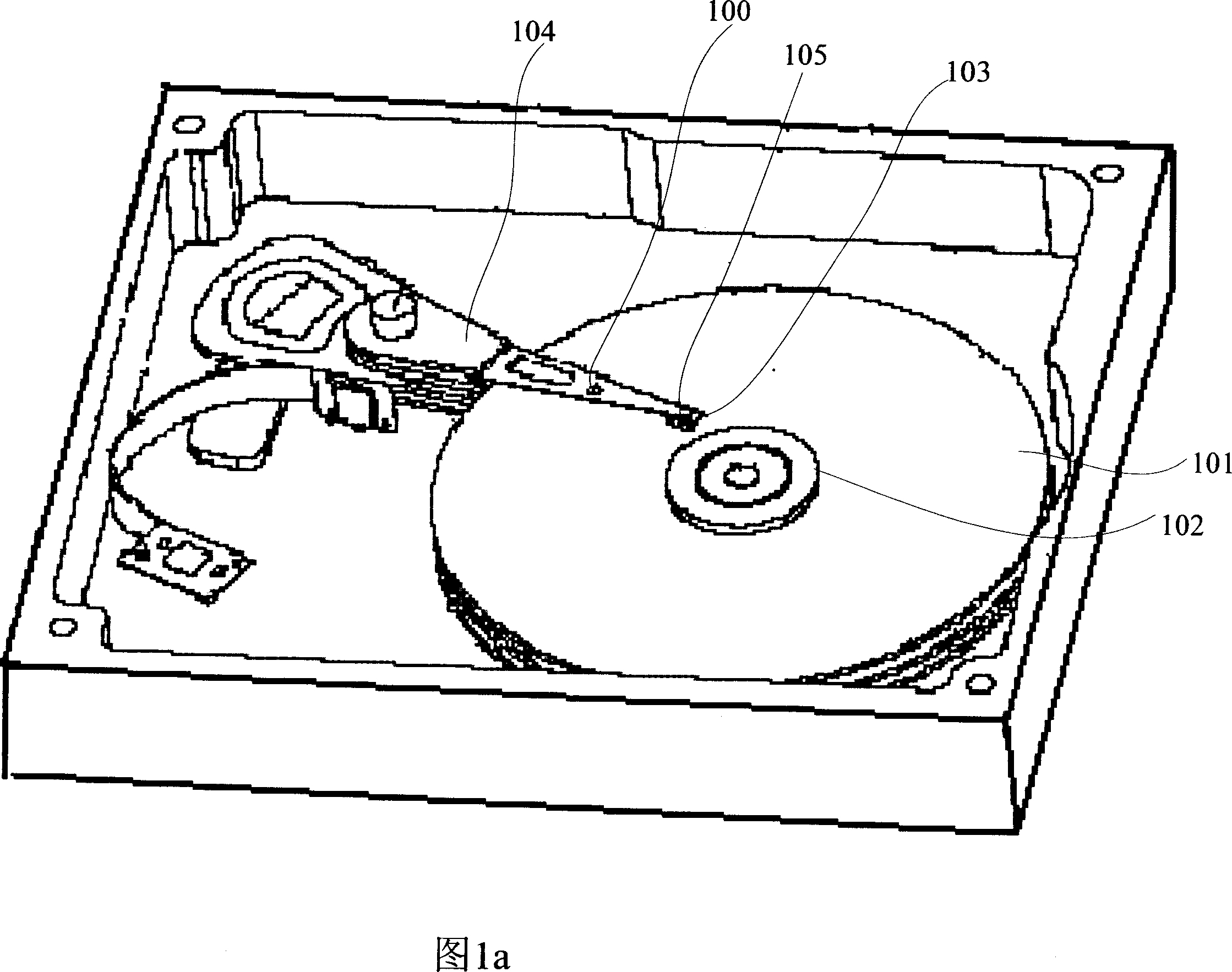

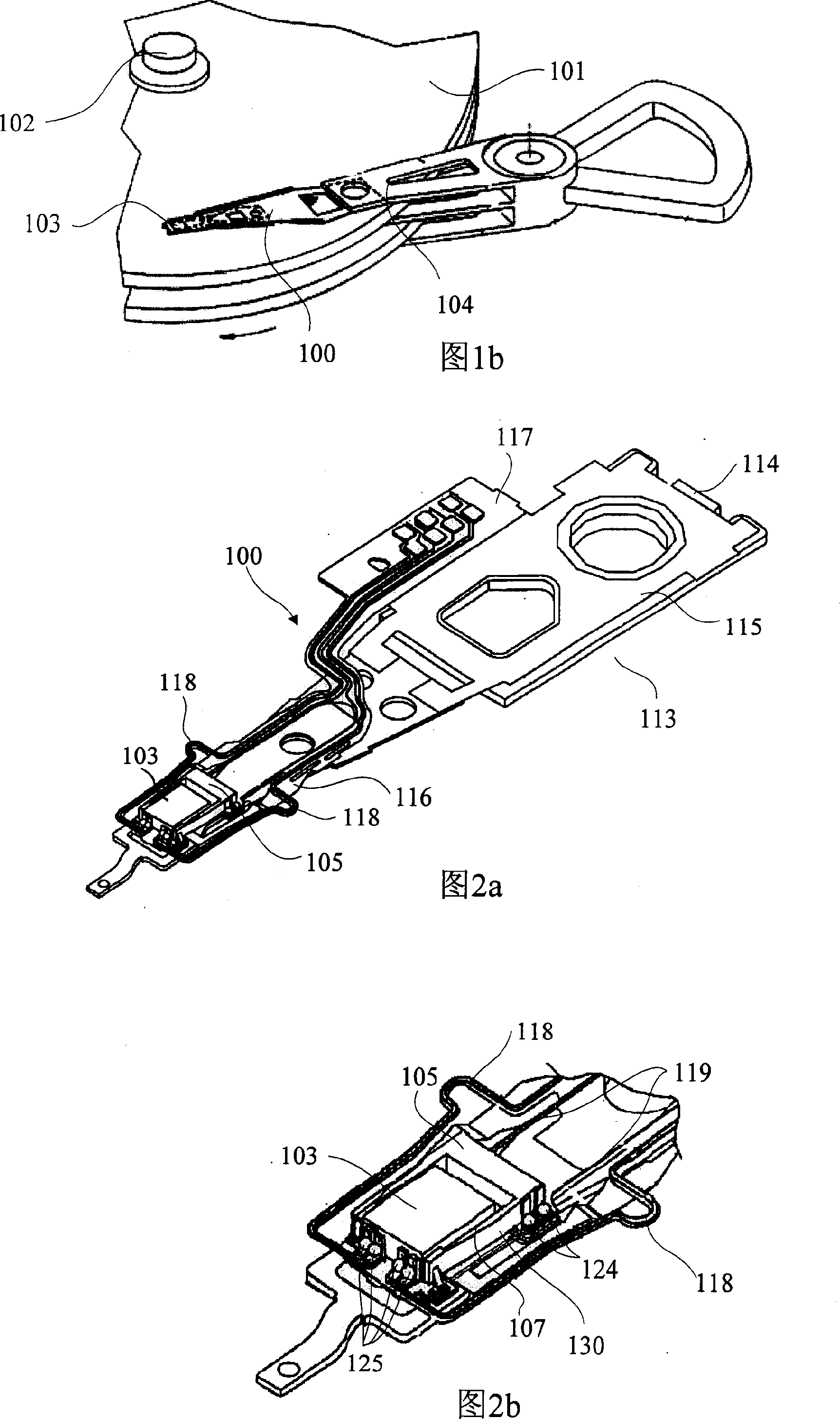

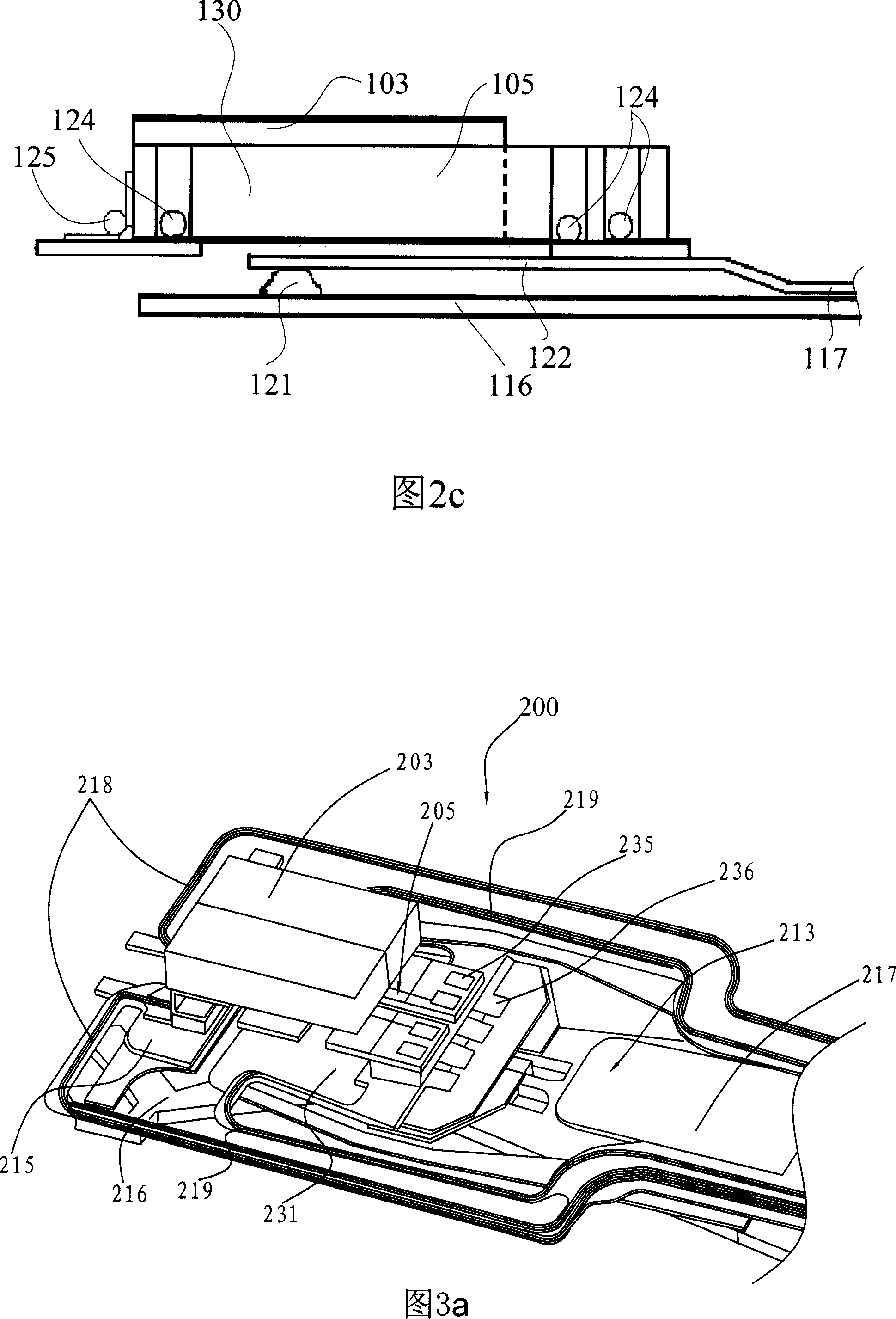

[0077] Fig. 3a-7b has shown the microdrive described in an embodiment of the present invention, wherein, Fig. 3a-3c have shown the state that this microdrive is installed on a magnetic head gimbal assembly, and Fig. 3d has shown the magnetic head gimbal shown in Fig. 3a A partial perspective view of the cantilever of the sheet assembly. As shown in the figure, the HGA 200 includes a piezoelectric micro-actuator 205 , a magnetic head 203 mounted on the piezoelectric micro-actuator 205 , and a suspension member 213 for supporting the piezoelectric micro-actuator 205 and the magnetic head 203 .

[0078] The suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com