Direct type backlight module

A backlight module, direct-type technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased frame production cost, increased backlight module weight, and complicated assembly, achieving light weight, improved assembly speed, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

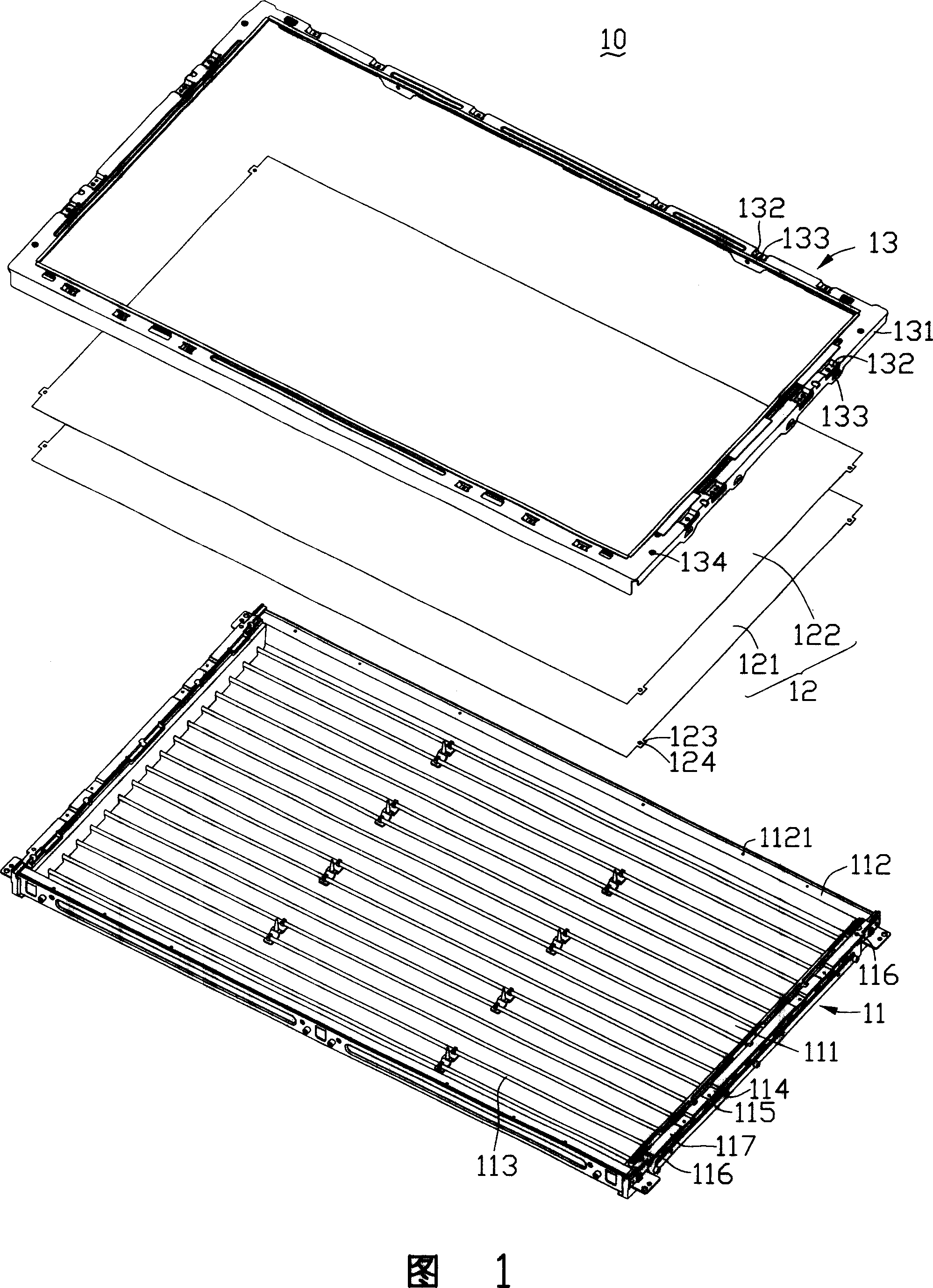

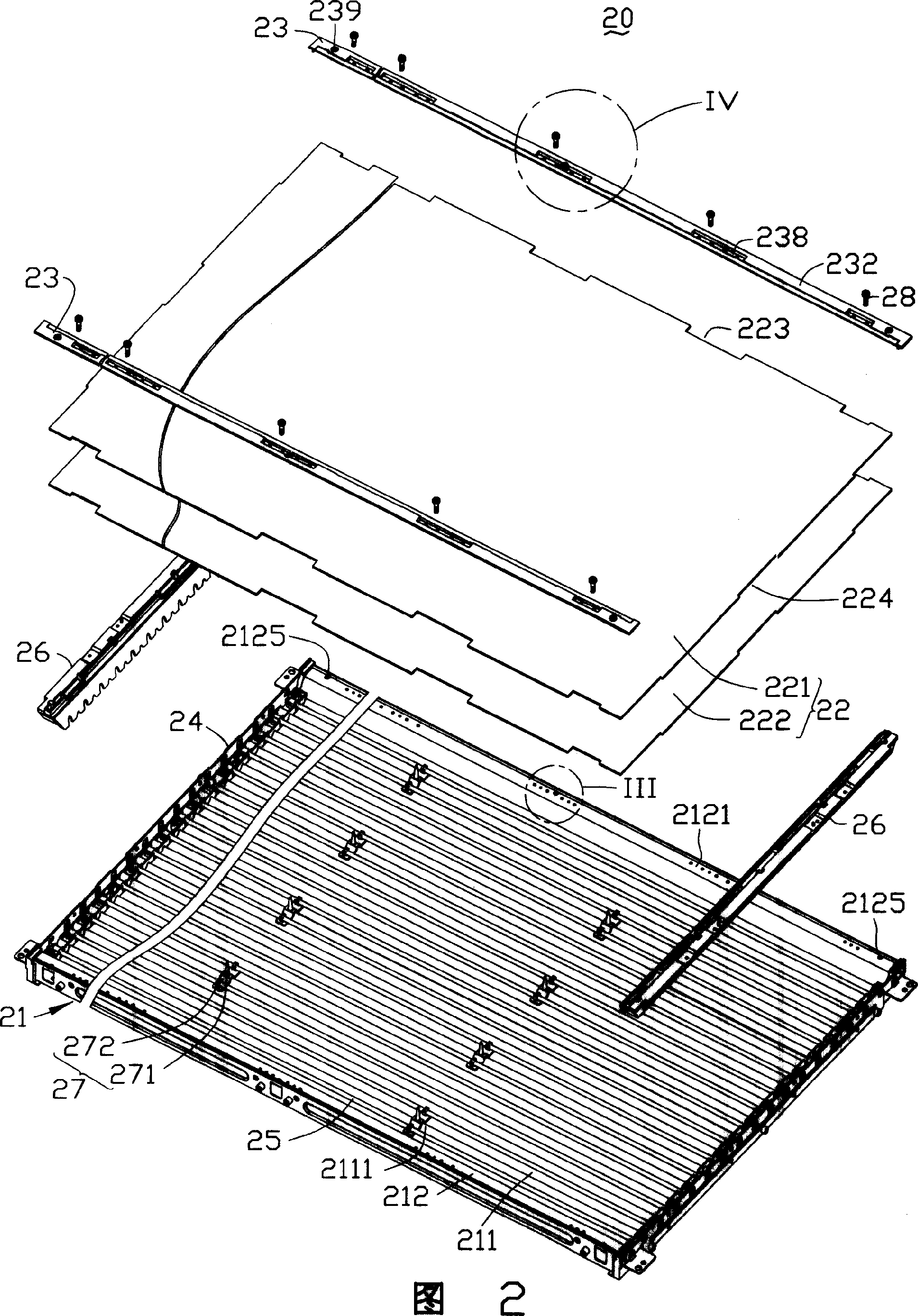

[0020] The direct type backlight module and its frame of the present invention will be further described in detail below with reference to the drawings and embodiments.

[0021] Please refer to Fig. 2, the preferred embodiment of the present invention provides a direct-type backlight module 20, which includes a reflector 21, two optical films 22, two fixed frames 23, two lamp tube placement racks 24, and a plurality of lamps Tube 25, two lamp tube protection frames 26, multiple lamp tube clamping devices 27 and multiple screws 28.

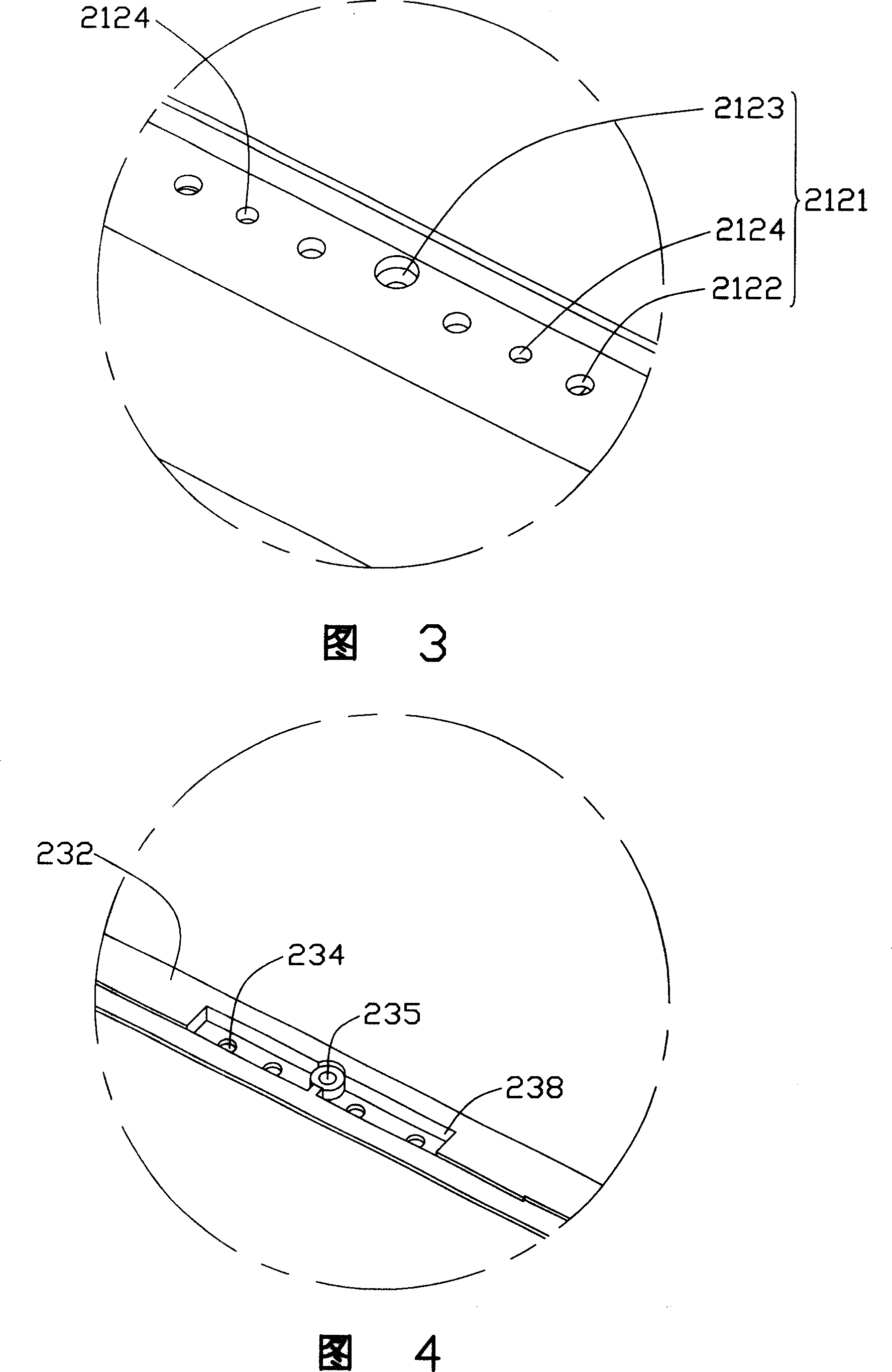

[0022] The reflecting plate 21 includes a bottom plate 211 and two sidewalls 212 . The bottom plate 211 is a rectangular curved plate structure with a plurality of protrusions 2111 formed on its surface. The two sidewalls 212 vertically extend upward from two opposite sides of the bottom plate 211 . A plurality of protrusions 2111 extend along a direction parallel to the sidewall 212 and are arranged periodically at intervals.

[0023] Please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com