A wind turbine blade equipped internally with collection means

A technology of wind power generators and collection devices, applied in the field of blades, can solve problems such as endangering the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

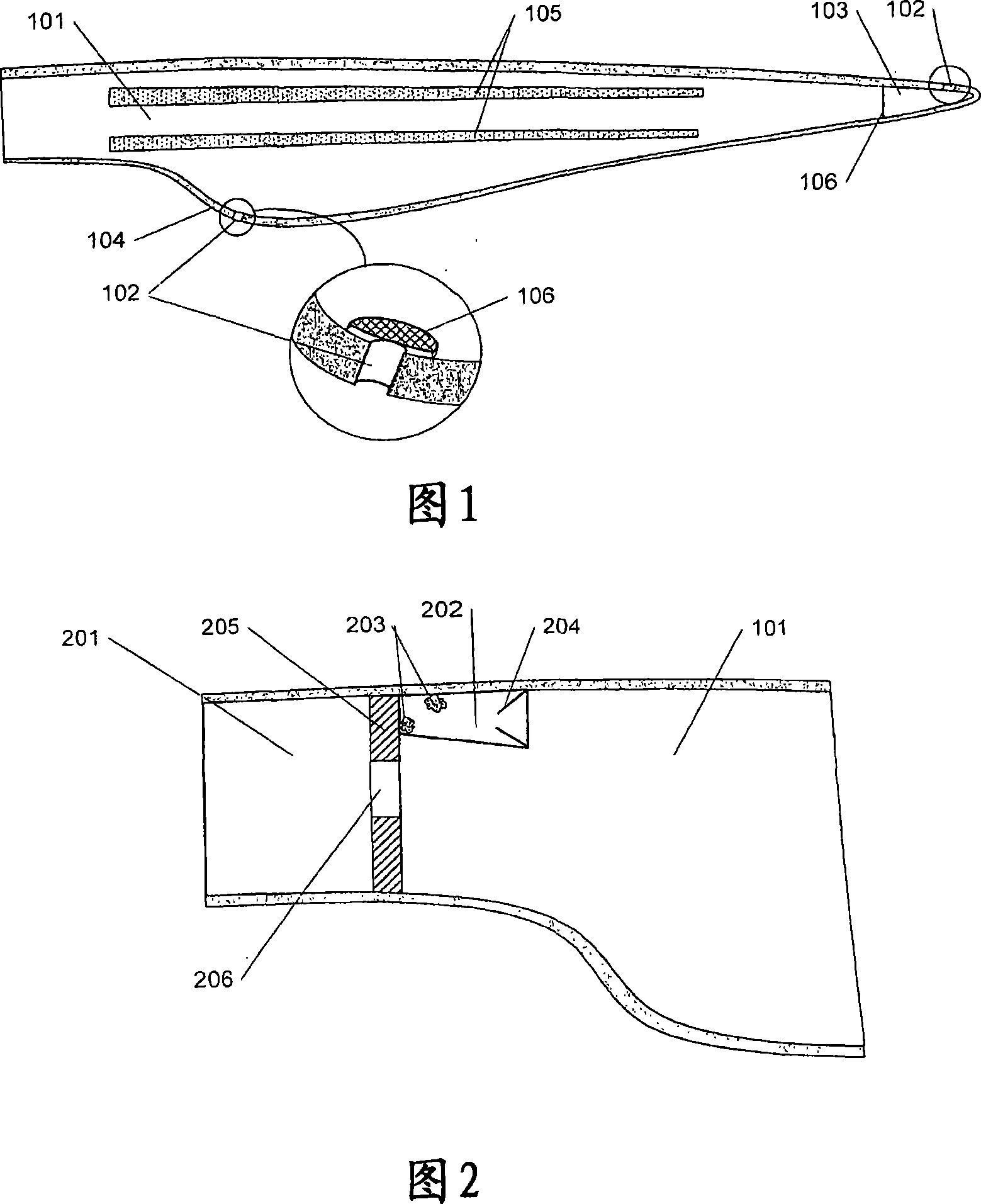

[0025] Figure 1 is a cross-sectional view of a blade 101 for a wind turbine. Typically, a blade is assembled from two blade shells and some internal support posts 105 so that the blade includes one or more cavities. In order to also allow moisture to flow out of the blade during use, a plurality of drainage holes 102 are provided on the blade. In the example given, the drainage holes 102 are provided at the tip 103 of the blade, and at the rear right of the outermost part of the rear edge 104 of the blade. According to one embodiment of the present invention, a plurality of filters 106 are provided inside the blade 101 . Advantageously, they are located in front of each drainage hole 102 so that objects or particles larger than the mesh of the filter cannot enter the drainage holes 102 and accordingly do not block the drainage holes. Smaller particles either pass through the filter or are captured by it. According to another embodiment of the invention, the filter is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com