Leveling machine for single beam

A single-piece beam and leveling machine technology, applied in the field of leveling machines, can solve the problems of large center distance of work rolls, affecting the quality of steel plate leveling, large volume, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

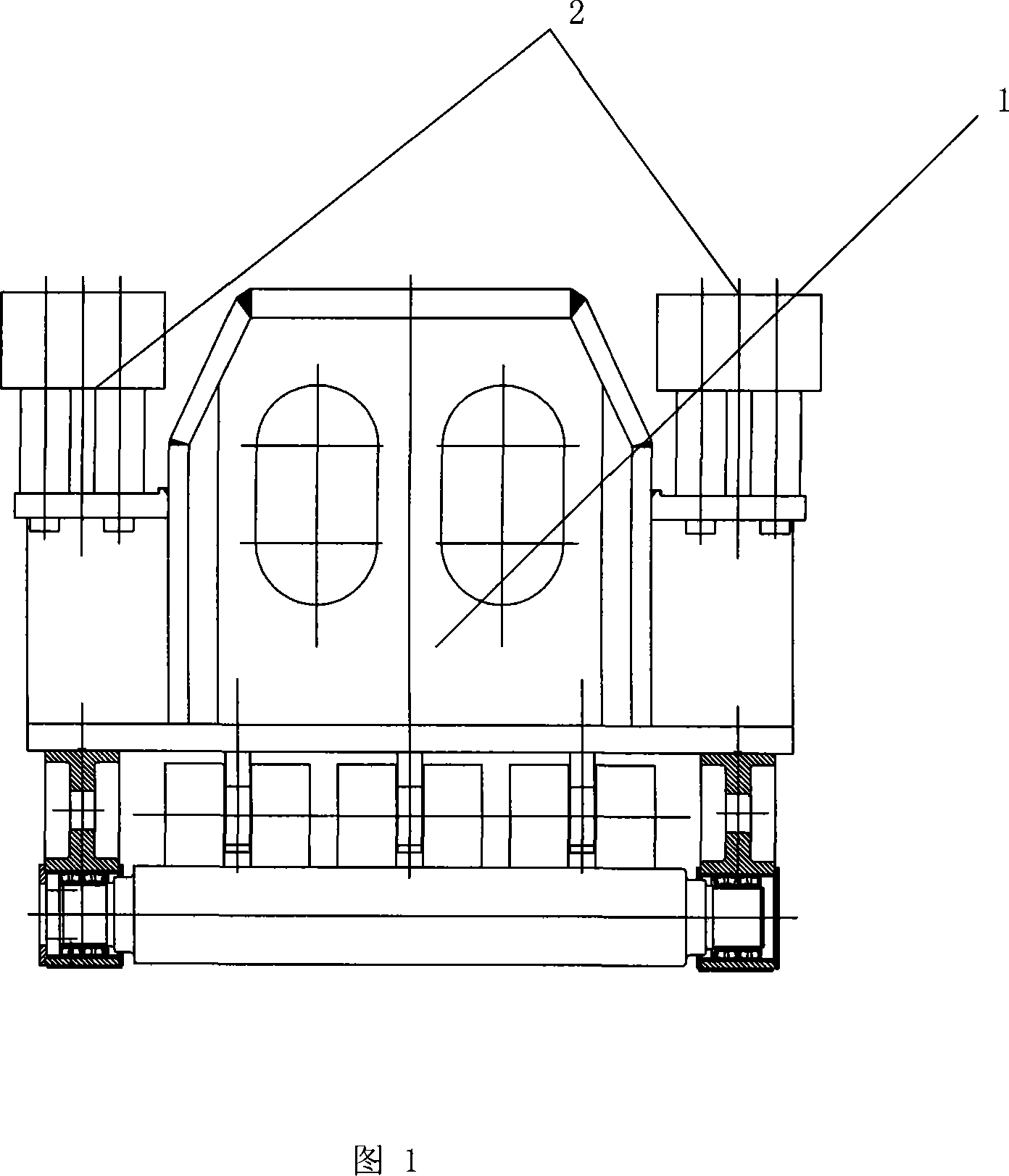

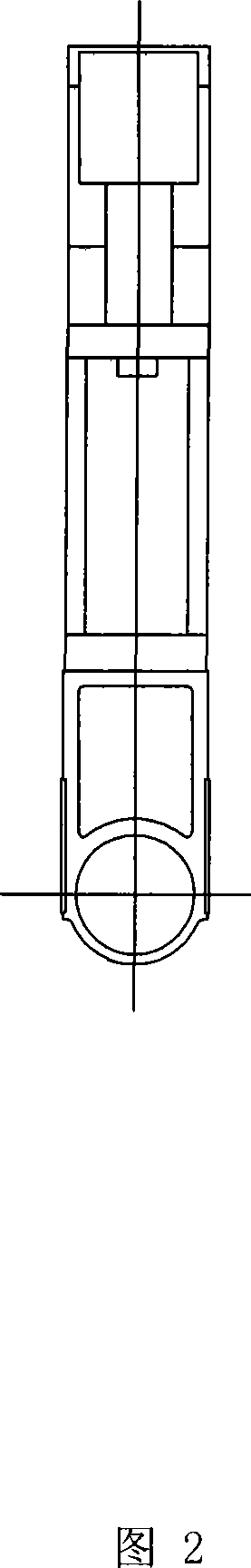

[0010] The present invention will be further described below in conjunction with the accompanying drawings. As shown in Fig. 1 and Fig. 2, the present invention discloses a single-piece beam leveling machine, comprising a single-piece beam 1 and an oil cylinder 2, and the oil cylinder 2 of the upper device at both ends of each single-piece beam 1 can be two one or more.

[0011] The single beam can be one or more of them, and there can be two or more oil cylinders installed on each head.

[0012] The oil cylinder can be a connected cylinder, a plunger cylinder, a sleeve cylinder, or a mixture of a piston cylinder and a plunger cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com