Method for final assembling transverse bulkhead and deck on ship

A technology of transverse compartments and decks, applied in the direction of hull, ship parts, hull parts, etc., can solve the problems of inconvenient operation, affecting the speed of the overall group, hidden dangers for the personal safety of operators, etc., to ensure personal safety and improve the overall group. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

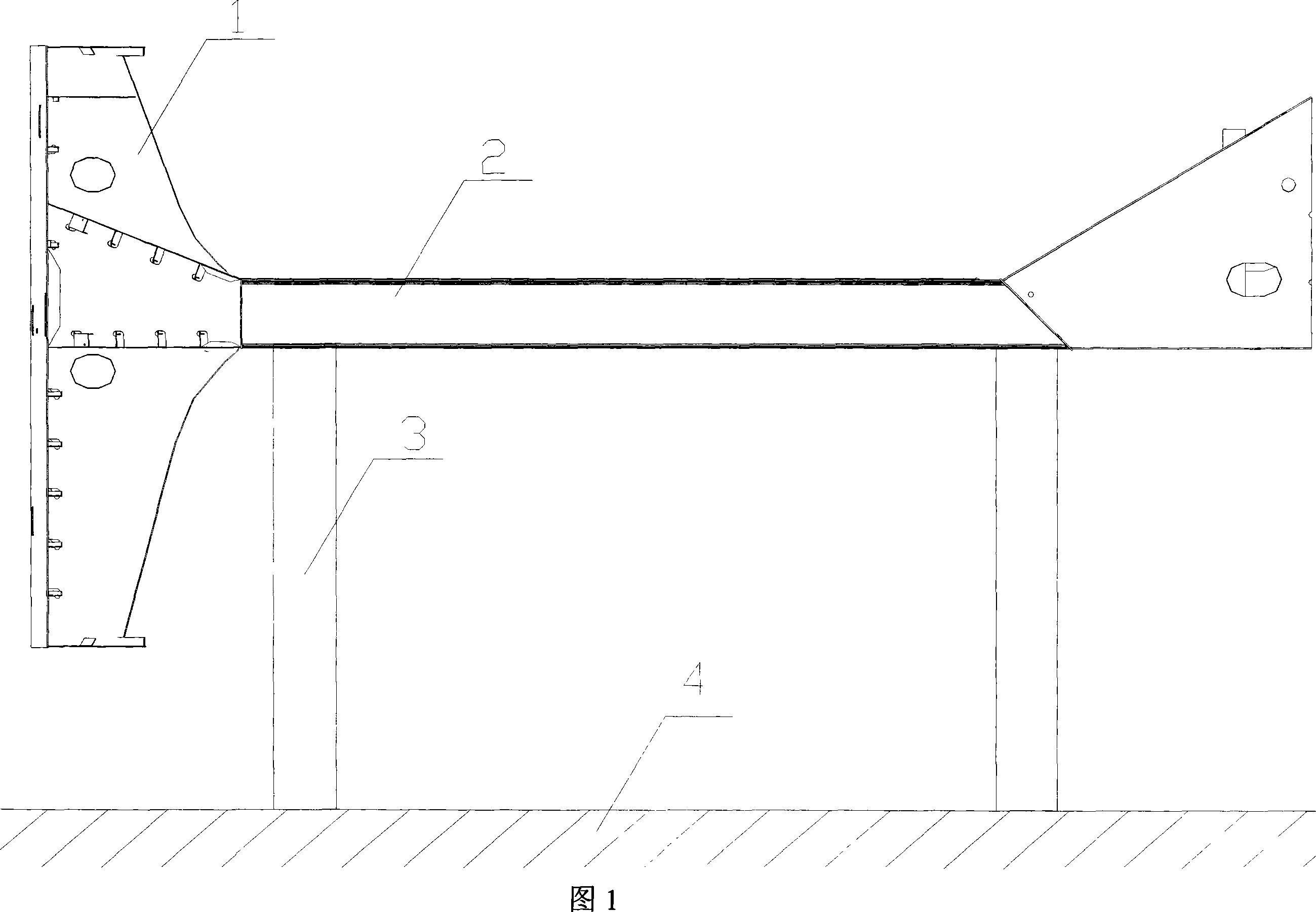

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0014] As shown in Figure 1, the method includes the following steps:

[0015] 1. Put the pier 3 of the transverse compartment 2 on the section of the inner bottom 4 in the dock to meet the height of the deck 1, so that the bottom of the deck 1 is a certain distance higher than the inner bottom 4 in the dock to facilitate the operation.

[0016] 2. Position the transverse compartment 2 and the deck 1, and perform welding installation after positioning.

[0017] 3. After the general assembly and welding, paint the deck 1 and the transverse compartment 2 as a whole.

[0018] 4. After the painting operation is completed, the overall section is hoisted onto the ship, and the overall assembly process of the transverse compartment 2 and deck 1 on the ship is completed.

[0019] Through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com