Process for preparing peanut oil and peanut protein powder synchronously

A technology of peanut protein powder and peanut oil, which is applied to the protein composition of vegetable seeds, protein food ingredients, edible oil/fat, etc., can solve the problems of long process cycle, solvent residue, poor protein functionality, etc., and achieve a wide range of applications, The effect of frying with less oily smoke and low phospholipid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

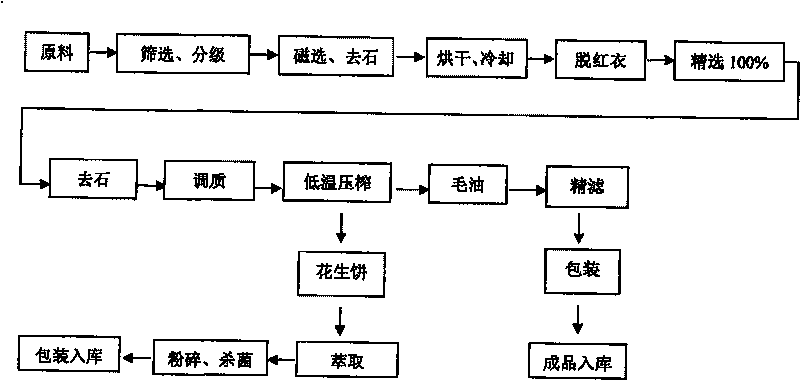

[0031] Embodiment 1, the method for synchronously producing peanut oil and peanut protein powder at low temperature

[0032] The technical scheme for producing peanut oil and peanut protein powder provided by the present invention comprises the following steps:

[0033] ①Select first-grade peanuts as the raw material for oil production, remove stones and impurities, dry at 70°C and quickly cool to room temperature; half-grain machine, winnowing remove peanut red coat, manual selection removes moldy kernels and red coat dirt of peanuts;

[0034] ②The selected peanut kernels are tempered in the tempering tower, the tempering temperature is controlled at 70°C, the moisture is controlled at 5.0%, and the tempering time is 1.2 hours (if there is too much water loss during this time, you can add pure water to adjust);

[0035] The conditioning step is carried out in a conditioning tower. The model of the tempering tower used is the TZJ series tempering tower, which was purchased ...

Embodiment 2

[0047] Embodiment 2, the method for synchronously producing peanut oil and peanut protein powder at low temperature

[0048] The technical scheme for producing peanut oil and peanut protein powder provided by the present invention comprises the following steps:

[0049] ①Select first-grade peanuts as the raw material for oil production, remove stones and impurities, dry at 40°C and quickly cool to room temperature; half-grain machine, winnowing to remove peanut red coat, manual selection to remove moldy kernels and red coat impurities of peanuts;

[0050] ②The selected peanut kernels are conditioned in the conditioning tower, the conditioning temperature is controlled at 60°C, the moisture is controlled at 5.0%, and the conditioning time is 0.8 hours;

[0051] ③The conditioned peanut kernels are squeezed once through a 200-type oil press. The working pressure of the oil press is 39.5MPa, and the pressing time is 4.5 hours. , the pressed cake is sent to the extraction worksho...

Embodiment 3

[0062] Embodiment 3, the method for synchronously producing peanut oil and peanut protein powder at low temperature

[0063] The technical scheme for producing peanut oil and peanut protein powder provided by the present invention comprises the following steps:

[0064] ①Choose first-grade peanuts as the raw material for oil production, remove stones and impurities, dry at 90°C and quickly cool to room temperature; half-grain machine, winnowing to remove peanut red coat, manual selection to remove moldy kernels and red coat dirt of peanuts;

[0065] ②The selected peanut kernels are tempered in the tempering tower, the tempering temperature is controlled at 80°C, the moisture is controlled at 2.0%, and the conditioning time is 2 hours (if there is too much water loss during this time, you can add pure water to adjust);

[0066] ③The conditioned peanut kernels are squeezed once through a 200-type oil press. The working pressure of the oil press is 40.5MPa, and the oil extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com