Pruning machine

A technology of a pruning machine and a casing, applied in the field of pruning machines, can solve the problems of reduced friction between bushings and gears, weakened elastic effect of a disc spring, and users cannot make quick judgments, etc., and achieves strong elastic automatic compensation capability, The effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

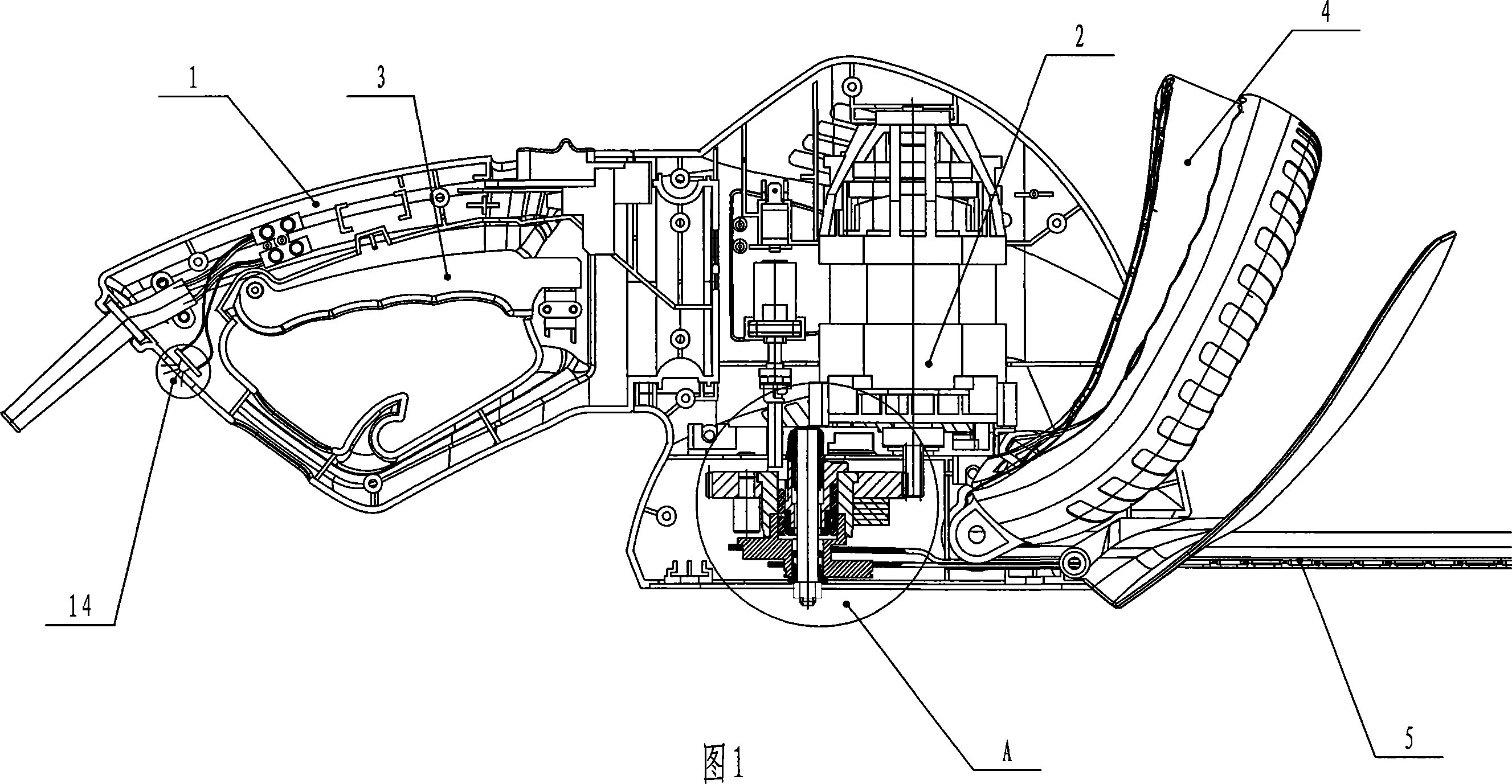

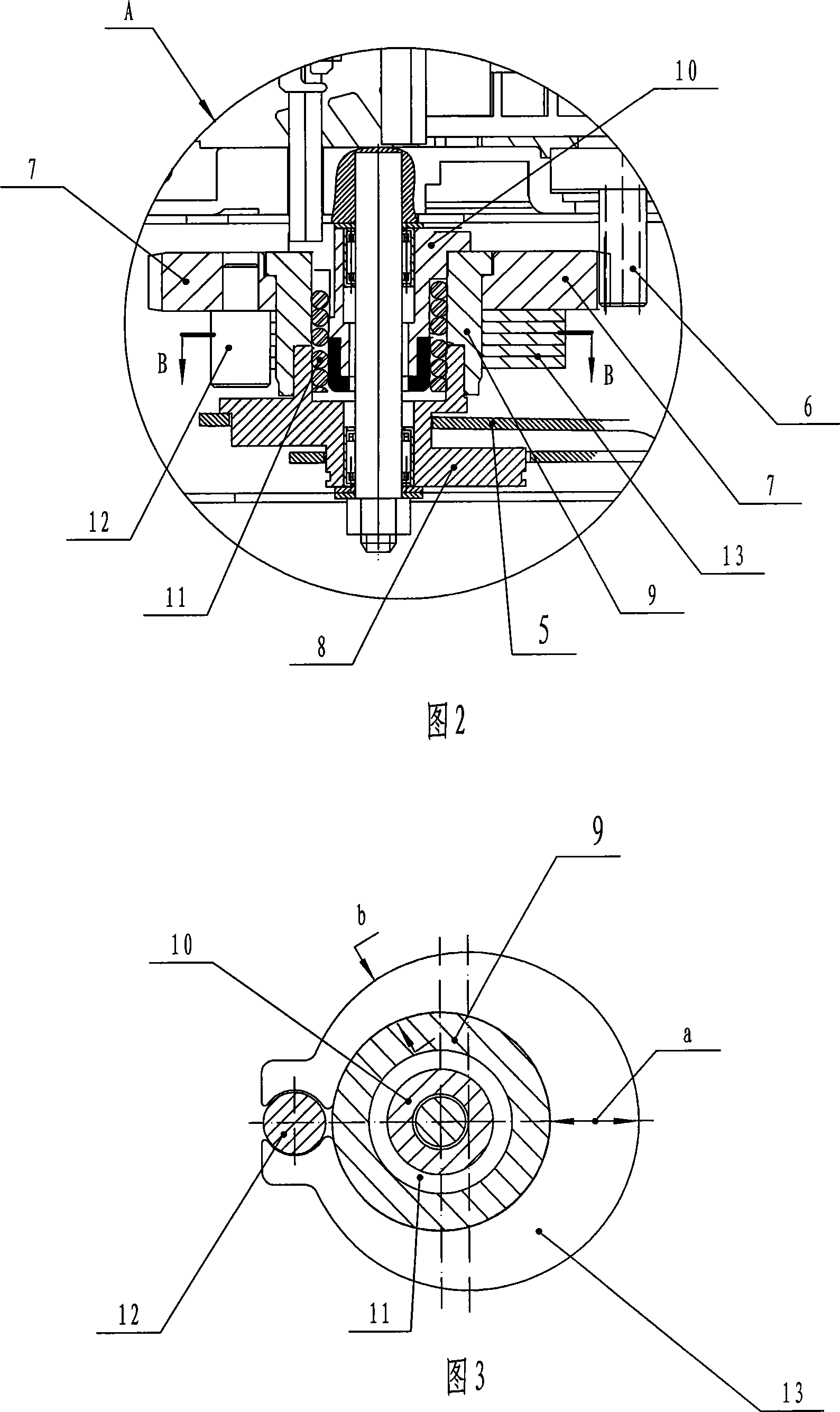

[0017] As shown in FIGS. 1 , 2 and 3 , the pruning machine of the present invention mainly includes a casing 1 , a motor 2 , a transmission mechanism, a main handle 3 , an auxiliary handle 4 and a blade 5 . The transmission mechanism is composed of an input gear 6, an output gear 7 and an eccentric block assembly; the eccentric block assembly includes an eccentric block 8 that causes the blade 5 to reciprocate due to rotational motion, an eccentric block outer cover 9, and an eccentric block outer cover 9. brake block 10 and torsion spring 11. The eccentric block casing 9 is integrated with the eccentric block 8 through the brake block 10 and the torsion spring 11; On the circular step, the other end is tightly fitted on the outer circular step of the brake block 10; the input gear 6 and the output gear 7 mesh with each other.

[0018] The above st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com