Pure tea cream and its producing technology

A production process, Pu-erh tea technology, which is applied in the field of tea deep processing and production process, can solve the problems that the production process is too simple, and there is no specific expression for the greening process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

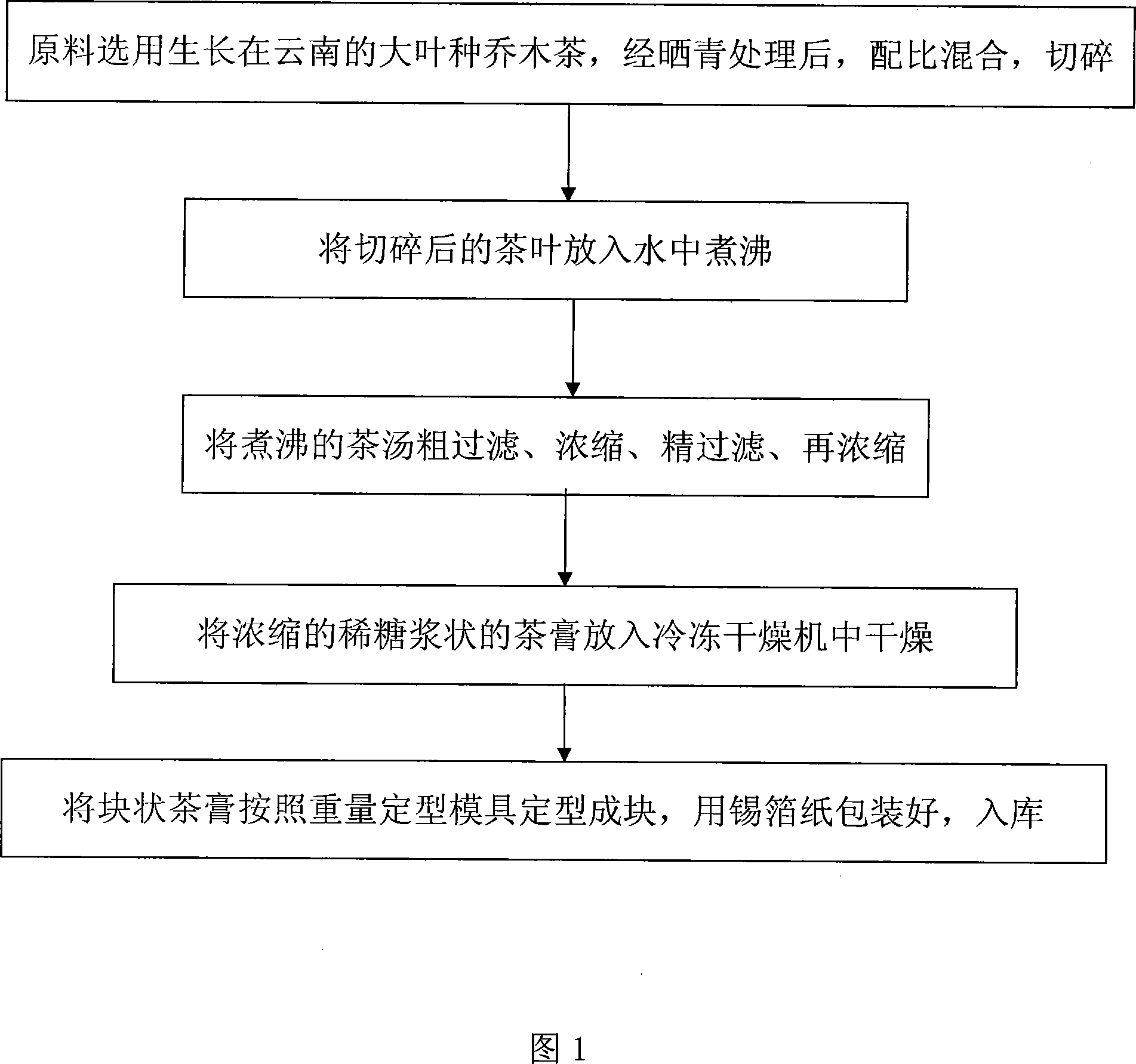

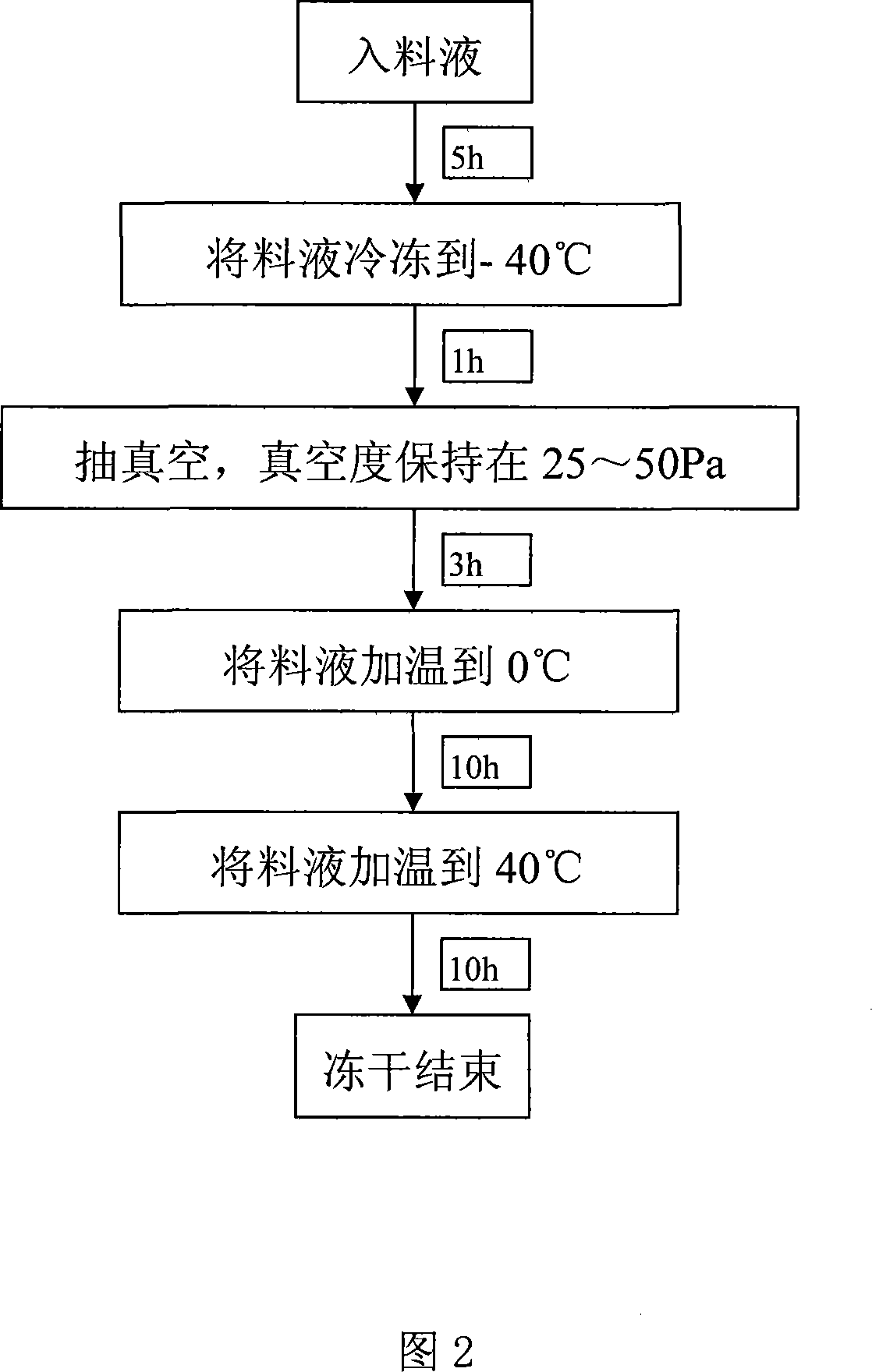

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. A kind of Pu'er tea tea paste suitable for large-scale, batch production, its production technology is as follows:

[0034] A-1. The raw materials are large-leaf tea grown in Yunnan, which is processed by the drying process and then chopped; according to the weight of the tea leaves of different natural fermentation times, 1 kg of tea leaves that have been naturally fermented for more than 3 years, naturally 2 kilograms of tea leaves fermented for 1 year to less than 3 years, and the weight portion of naturally fermented tea leaves less than 1 year is 7 kilograms, and the 10 kilograms of tea leaves are chopped.

[0035] A-2. Use 500kg of pure water, mineral water, or mountain spring water, and add 1kg of grain wine with an alcohol content of not less than 50 degrees in the water; take 500kg of water that has been added with grain wine and 10kg The crushed tea leaves are put together in a container and boiled.

[0036] A-3. the time that tea leaves and the...

Embodiment 2

[0048] Embodiment 2. a kind of Pu'er tea tea paste suitable for large-scale, batch production, its production technique is as follows:

[0049]B-1. The raw materials are large-leaf tea grown in Yunnan, which is processed by the drying process and then chopped; according to the weight of the tea leaves of different natural fermentation times, the natural fermentation of more than 3 years of tea leaves is 15 kg; 25kg of tea leaves that have been fermented for 1 year to less than 3 years; 60kg of tea leaves that have been naturally fermented for less than 1 year, and the above 100kg of tea leaves are chopped.

[0050] B-2. Use 10,000 kilograms of pure water, mineral water, or mountain spring water, and add 10 kilograms of grain wine with an alcohol content of not less than 53 degrees in the water; take 10,000 kilograms of water that has been added with grain wine and 100 kilograms The crushed tea leaves are put together in a container and boiled.

[0051] B-3. Put the tea leav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com