Hinge mechanism

A technology of hinge structure and pivot, which is applied in the field of hinge structure of liquid crystal displays, can solve the problems of poor limit effect and stability, easy wear of limit holes, etc., and achieve good effect of limit effect and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

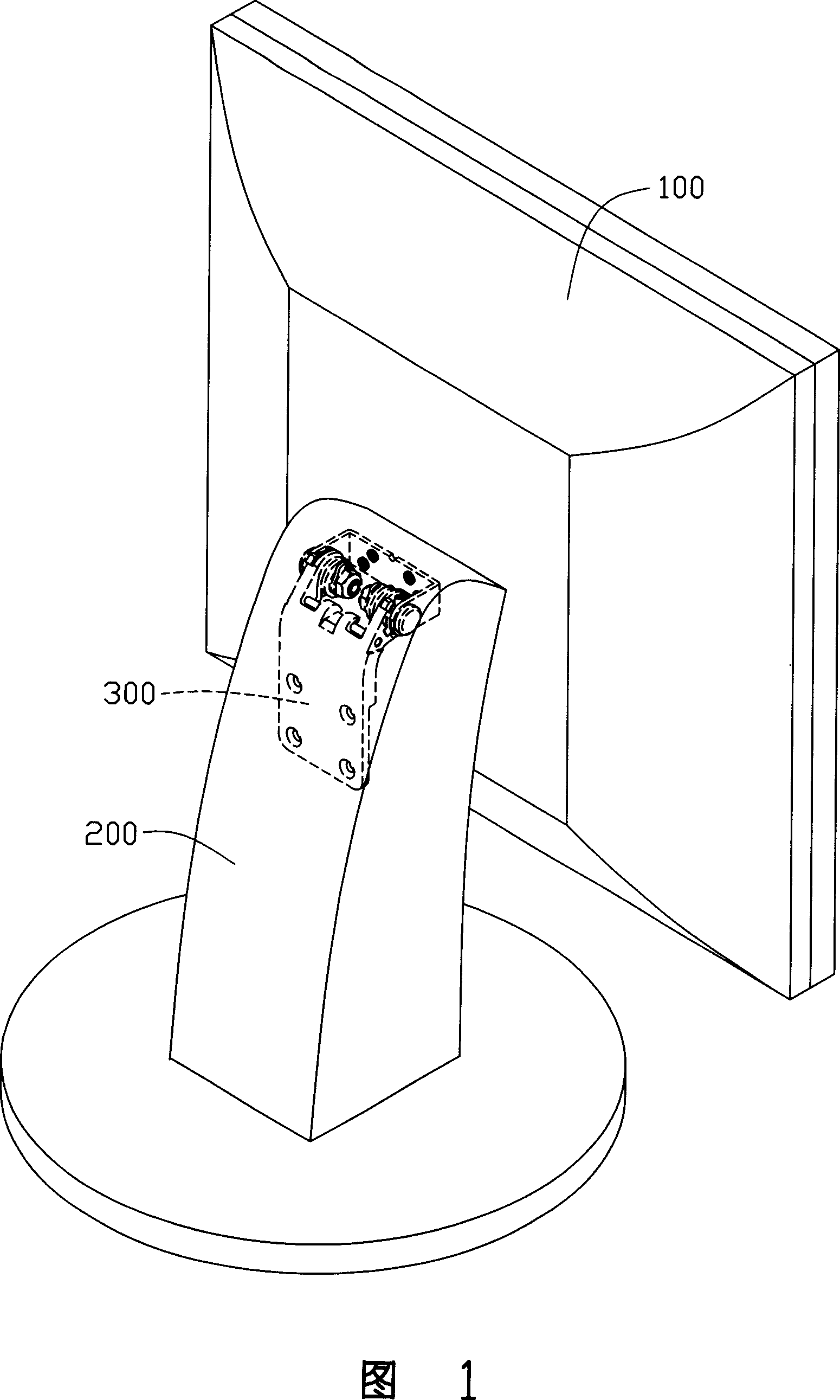

[0012] The hinge structure of the present invention is described by taking the application of the liquid crystal display as an example. Referring to FIG. 1, the liquid crystal display includes a display housing 100 and a base 200, which are rotatably connected by a hinge structure 300.

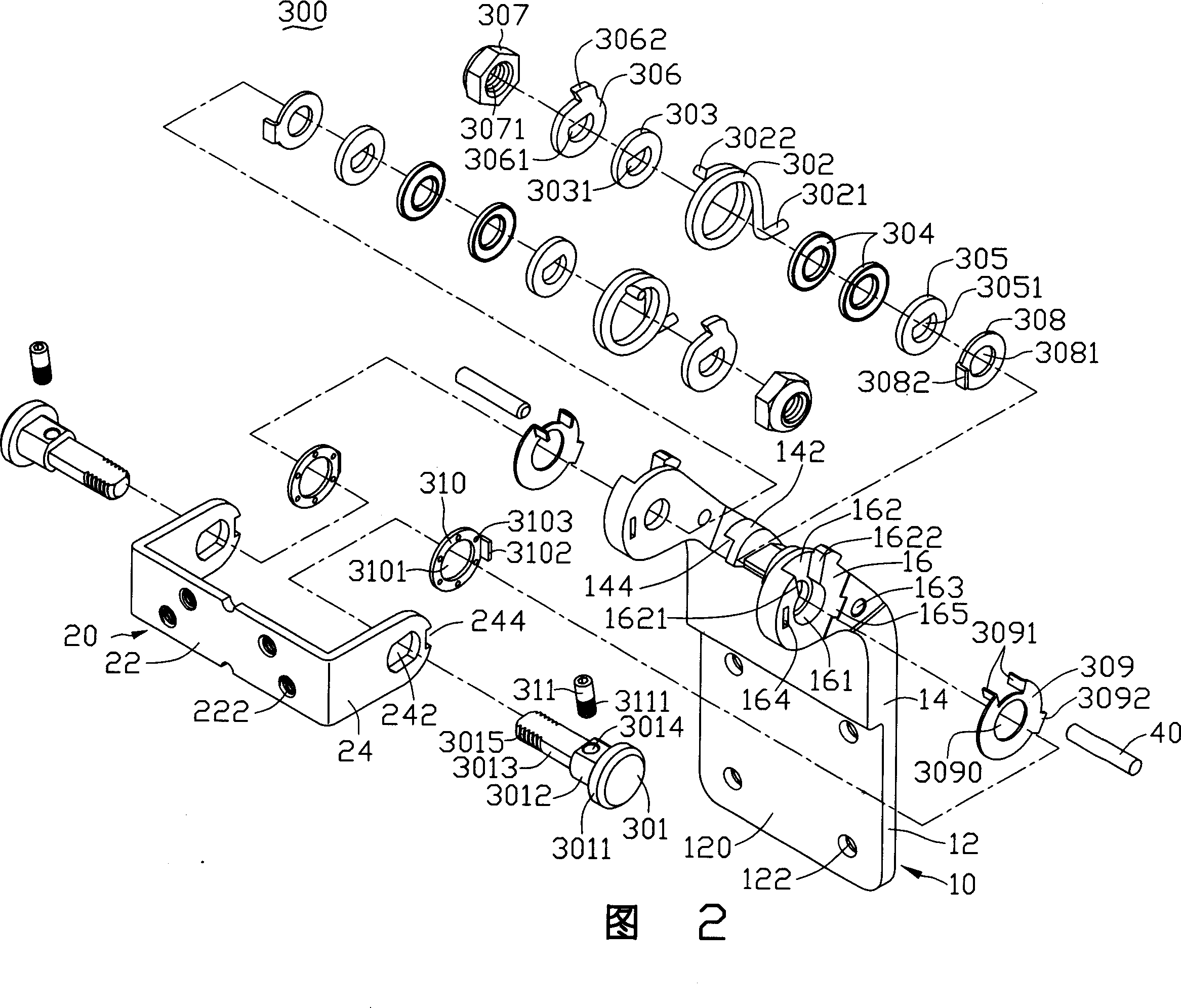

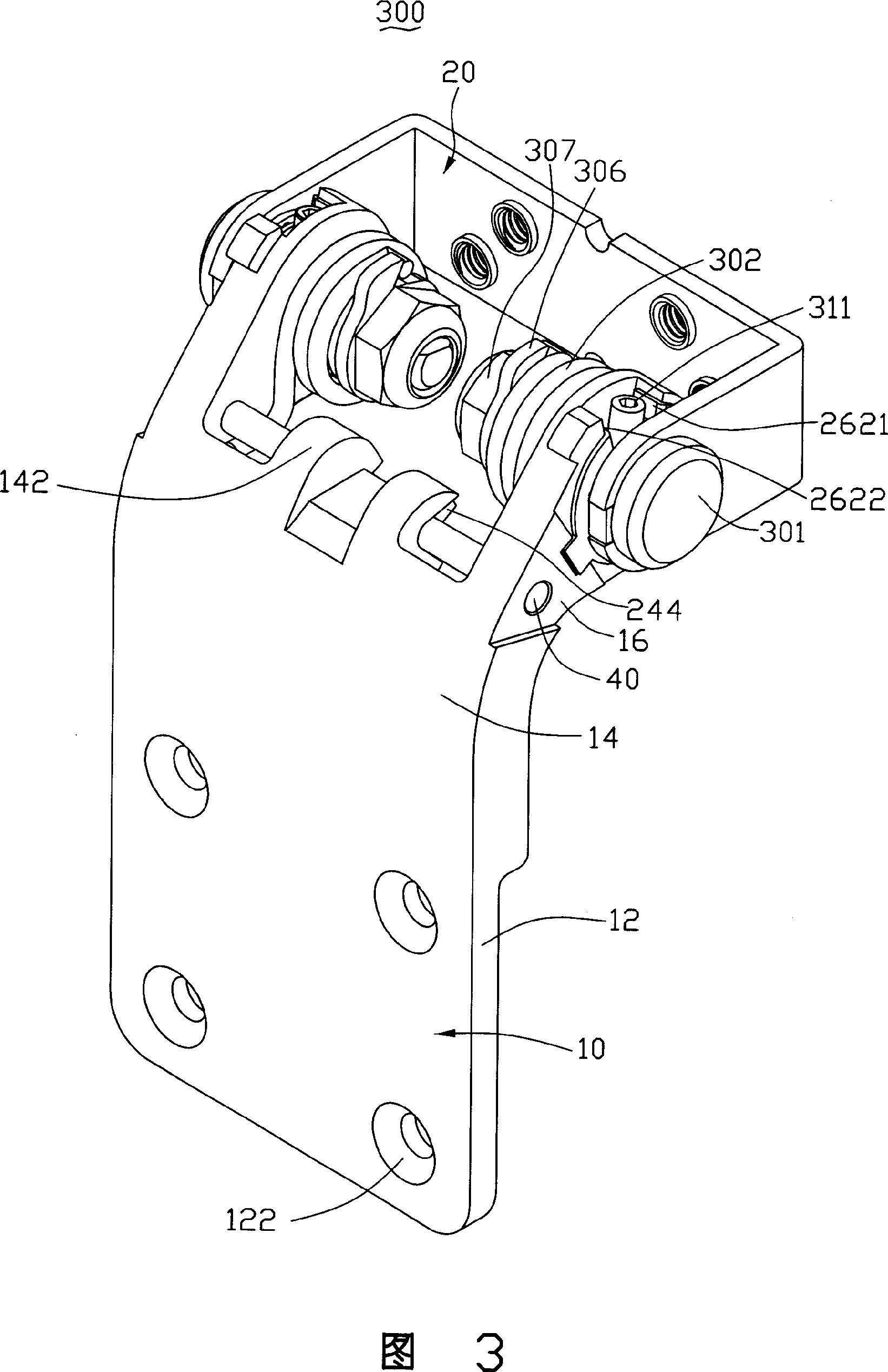

[0013] Please refer to FIG. 2, the hinge structure 300 includes a fixing member 10, a rotating member 20, and two pivoting components (not labeled). The fixed part 10 is connected to the base 200, the rotating part 20 is connected to the display housing 100, and the pivot assembly is used to connect the rotating part 20 and the fixed part 10 so that the rotating part 20 can rotate relative to the fixed part 10 within a certain angle range.

[0014] The fixing member 10 includes a mounting portion 12, a connecting portion 14 and two supports 16. The mounting portion 12 is plate-shaped and includes a mounting surface 120. The mounting portion 12 is evenly provided with four mounting holes 122, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com