Enlargement type staying cross rib square/rectangle steel tube concrete column

A technology for rectangular steel pipes and concrete columns, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of pipe wall buckling deformation and limited improvement of the overall restraint effect, and achieve the effect of increasing the buckling deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

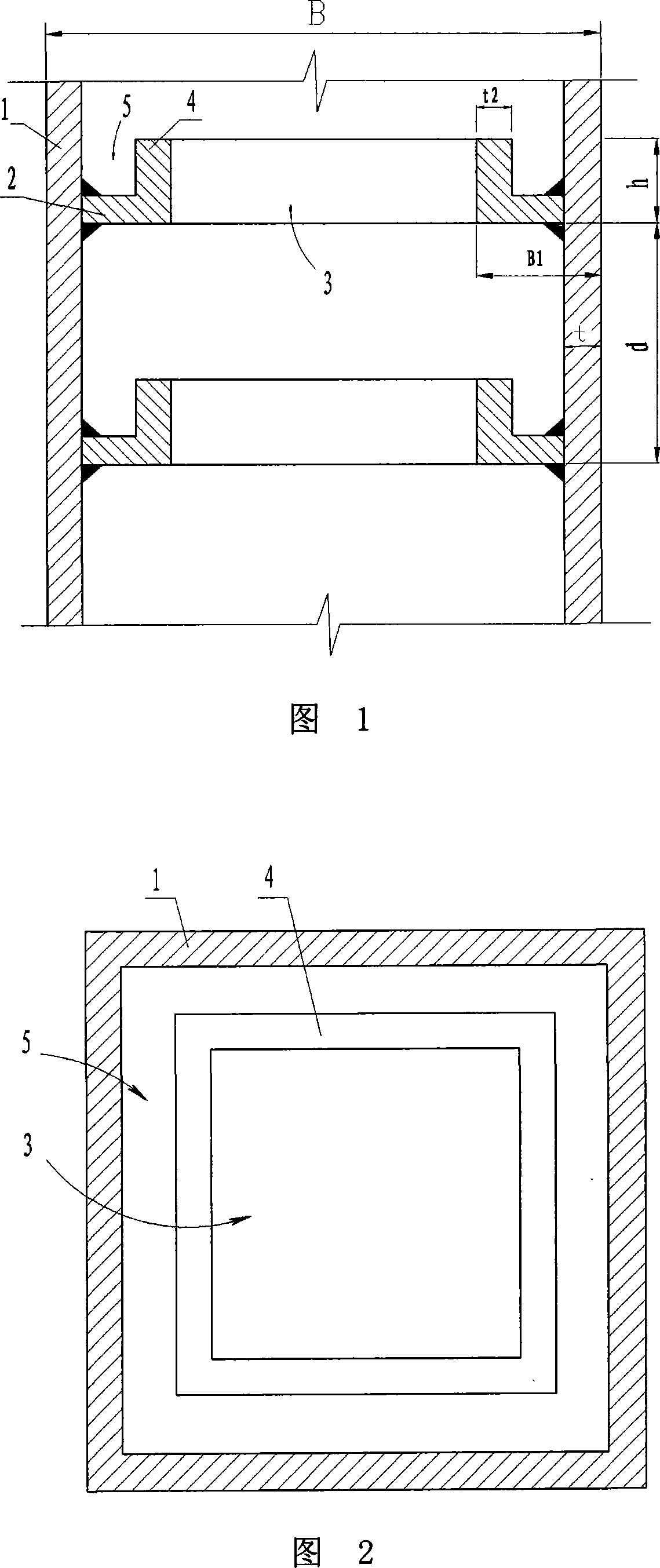

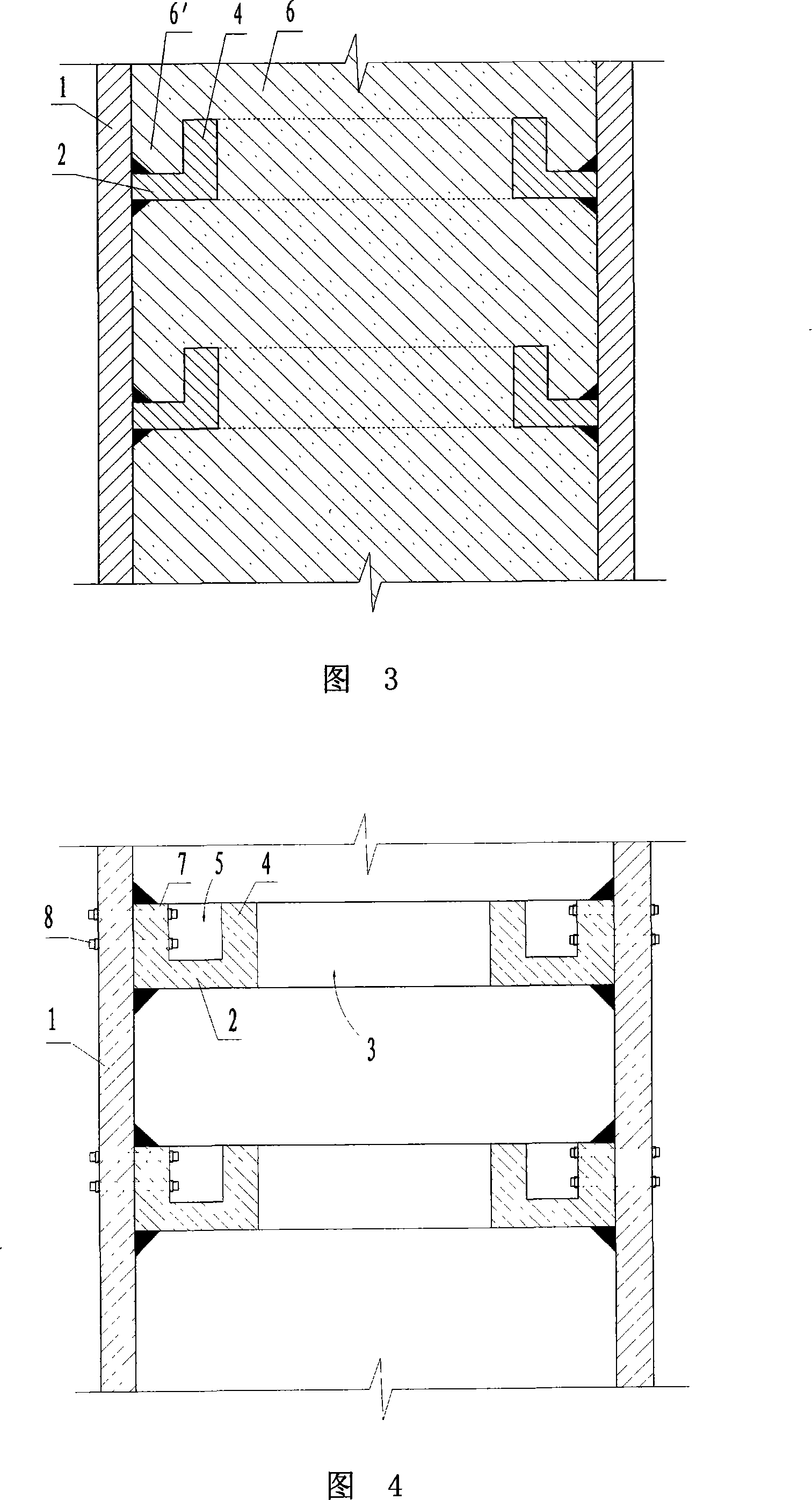

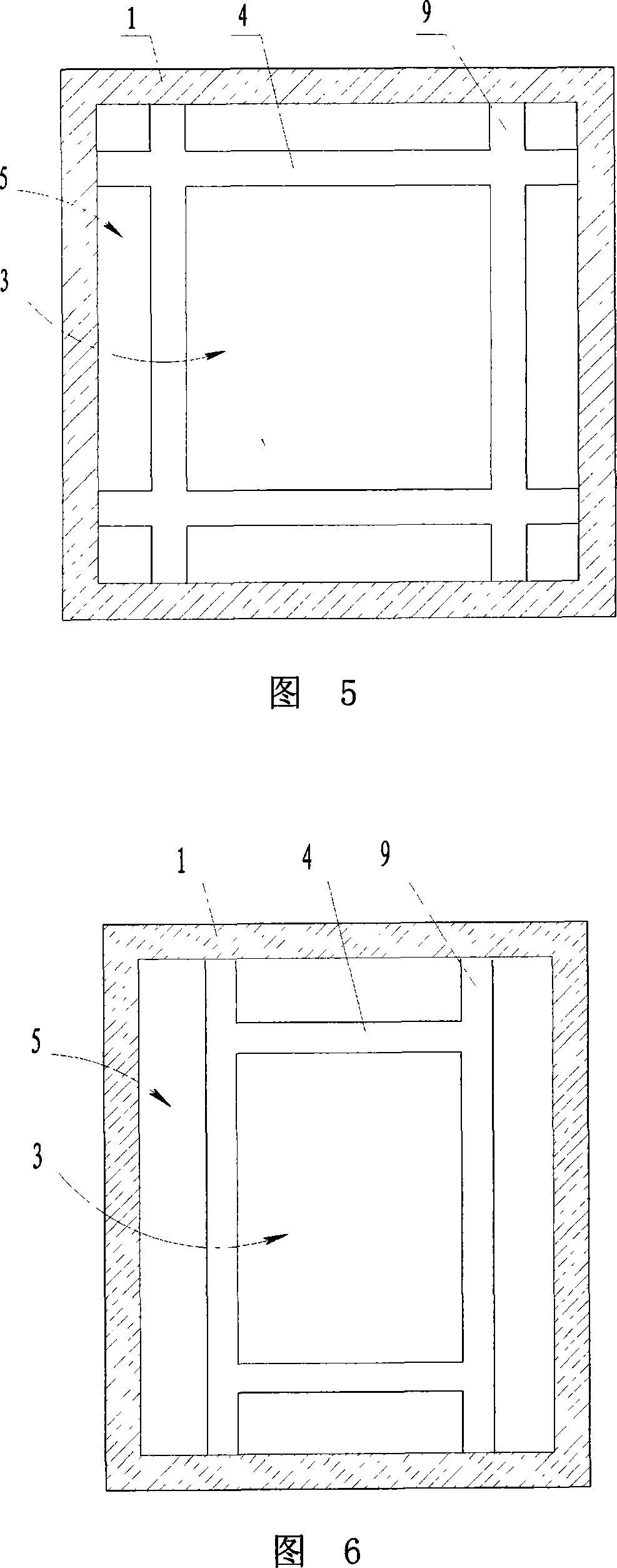

[0016] As can be seen from the longitudinal sectional view shown in Fig. 1, the basic structure of the present invention is that several stiffening transverse ribs 2 are arranged in the square steel pipe 1 between the building layers, and the center of each stiffening transverse rib 2 is provided with a concrete pouring hole 3, and the concrete The vertical plate 4 parallel to the pipe wall of the steel pipe 1 is provided around the pouring hole 3, and the vertical plate 4 is integrated with the stiffened transverse rib 2 to form the reinforced stiffened transverse rib of the present invention; it can be seen from Fig. 2 that the described A glyph-shaped annular groove 5 is formed between the vertical plate 4 and the pipe wall of the steel pipe 1, and the concrete 6' in the annular groove 5 dissolves into one with the concrete 6 in the entire steel pipe 1 (see FIG. 3 ). Under the enveloping effect of the pipe wall of the steel pipe 1, the reinforced stiffening transverse rib an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com