Modified double-layered steel plate concrete shear wall and construction method thereof

A steel plate concrete and construction method technology, applied in walls, building components, buildings, etc., can solve problems such as elastic-plastic local buckling, improve the ability to resist buckling deformation, save welding work, and improve overall restraint and shear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

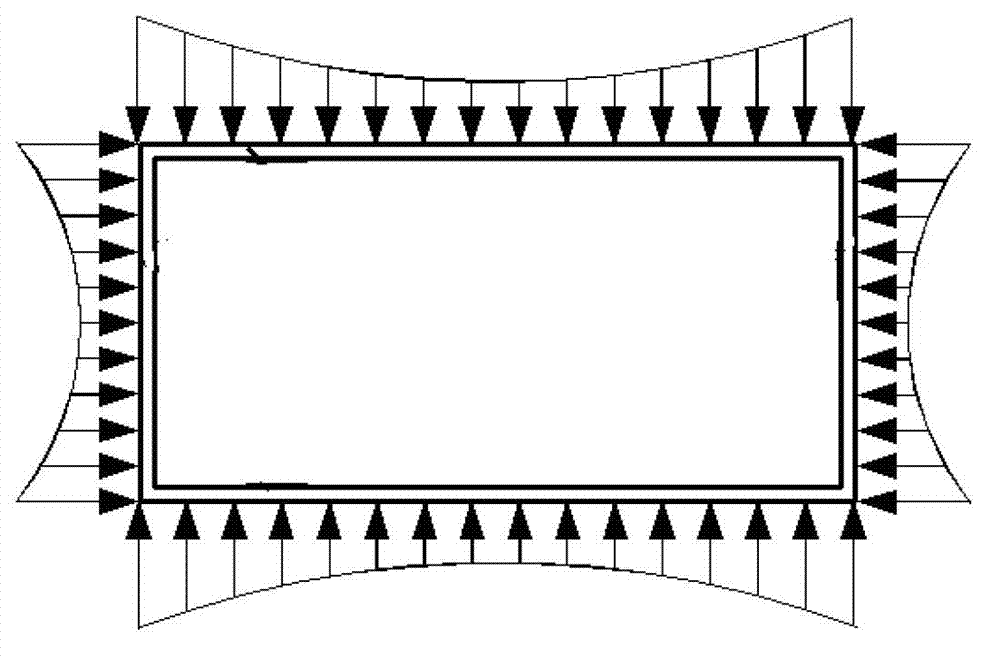

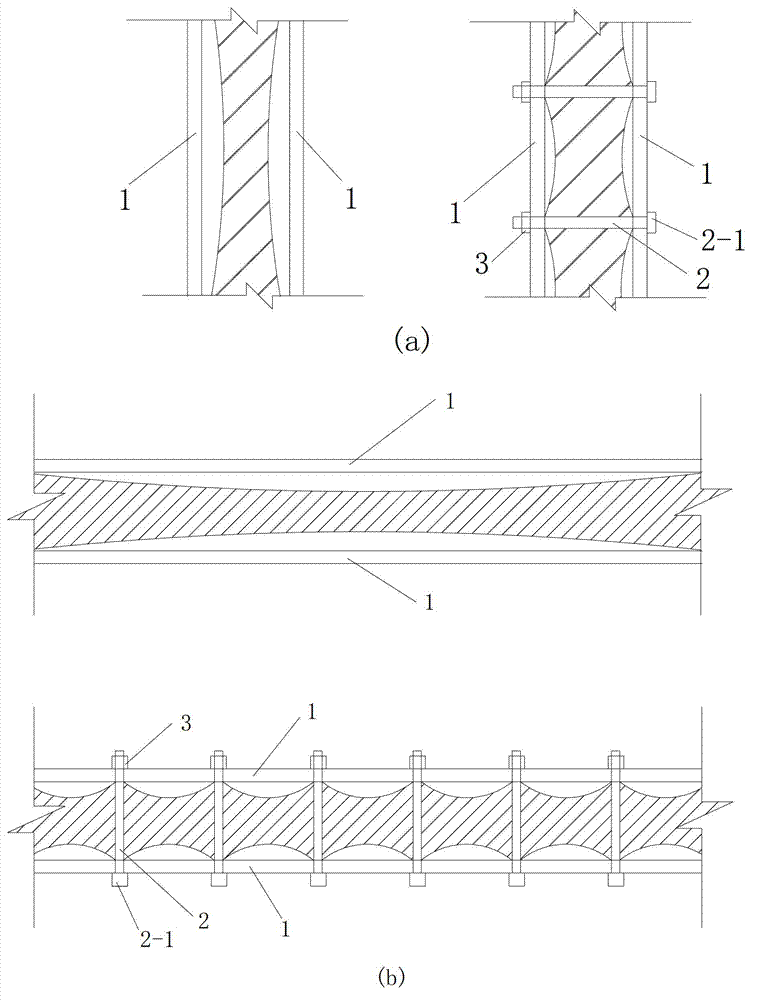

[0043] see Figure 4 and Figure 5 The improved double-layer steel plate concrete shear wall of this embodiment is set in the rectangular space surrounded by the beam 6 (including the upper beam and the lower beam) and the frame column 7 (including the left frame column and the right frame column). The force wall is composed of two opposite rectangular steel plates 1 , a concrete wall 4 filled between the two steel plates 1 , restraining rods 2 connected to the two steel plates 1 , stiffening strips 5 and nuts 3 .

[0044] The restraint rods 2 are arranged longitudinally and transversely to form a matrix of 6 rows×6 columns, and the steel plate 1 is provided with holes through which the restraint rods 2 are installed corresponding to the installation positions of the restraint rods 2 .

[0045] The stiffening strip 5 is a strip-shaped steel plate with a rectangular cross section, which can be cut from corner materials; The strips 5a are arranged on the outside of the steel p...

Embodiment 2

[0049] see Figure 7 In this embodiment, on the basis of Example 1, transverse stiffening bands 5b are also arranged on the outside of the steel plate 1 (i.e., arranged in the horizontal direction). Correspondingly, the connection mode of the transverse stiffening strip 5 b to the steel plate 1 and the restraint tie rod 2 is the same as the connection manner of the longitudinal stiffening strip 5 a to the steel plate 1 and the restraint tie rod 2 . The intersecting parts of the longitudinal stiffening strips 5a and the transverse stiffening strips 5b are integrated, which can be formed by welding or integrally formed.

[0050] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

[0051] see Figure 8 , the figure shows the difference between the core concrete constrained area of the double-layer steel plate concrete shear wall with the restraint tie rod 2 and the improved double-layer steel plate concrete shear wall of the present embodimen...

Embodiment 3

[0053] see Figure 9 The difference between this embodiment and Embodiment 1 is that in this embodiment, the stiffening strip is a transverse stiffening strip 5b, which is arranged on the inner side of the steel plate 1, and the transverse stiffening strip 5b and There is no need for welding between the steel plates 1, and only the bolt connection structure in Embodiment 1 can be used.

[0054] This embodiment can save the welding process, shorten the construction period, and increase the construction speed. At the same time, setting the stiffening belt on the inner side of the steel plate 1 can prevent the stiffening belt from being exposed to the air, thereby saving the work of taking anti-oxidation measures for the stiffening belt. .

[0055] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com