Organic acid modified Si/TiO2/rGO@C lithium ion battery negative electrode material as well as preparation method and application thereof

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve unsatisfactory problems, and achieve easy industrial production, low synthesis cost, and high capacity The effect of retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

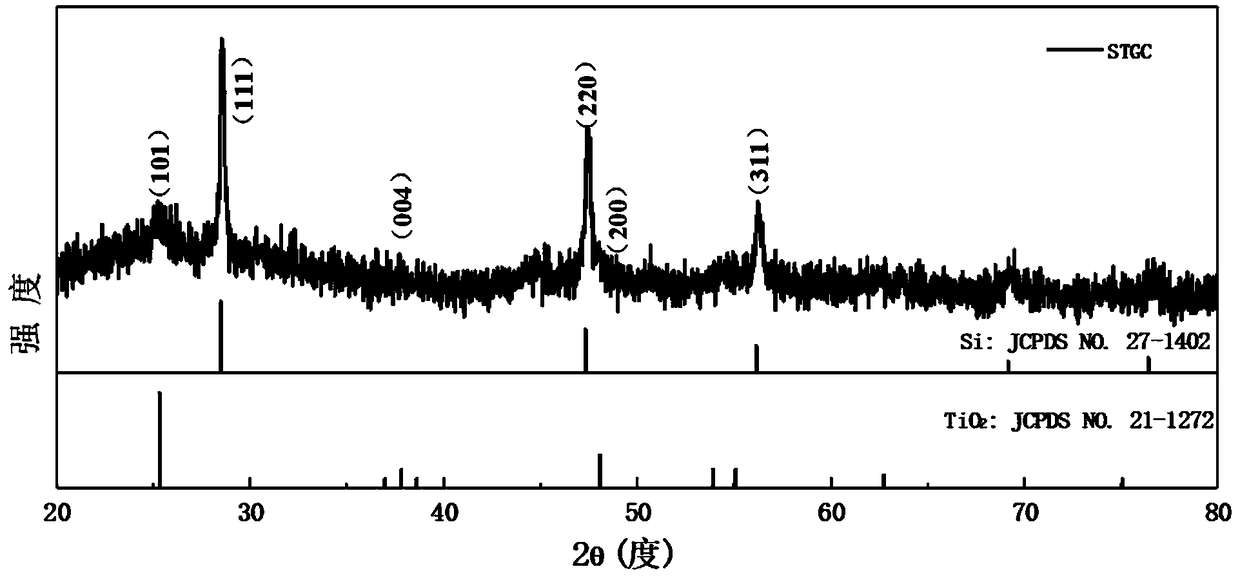

[0034] Organic acid modified Si / TiO of the present invention 2 The preparation method of / rGO@C lithium ion battery anode material includes the following steps:

[0035] S0: Use the modified Hummer method to prepare graphene oxide (GO), then add GO to a dispersion medium such as ethanol, and then perform ultrasonic dispersion treatment to make a GO dispersion with a concentration of 0.1-5 mg / mL, and then use a cell crusher To process the GO dispersion, the processing power of the ultrasonic cell pulverizer is 0-900W, and the processing time is 5-20min.

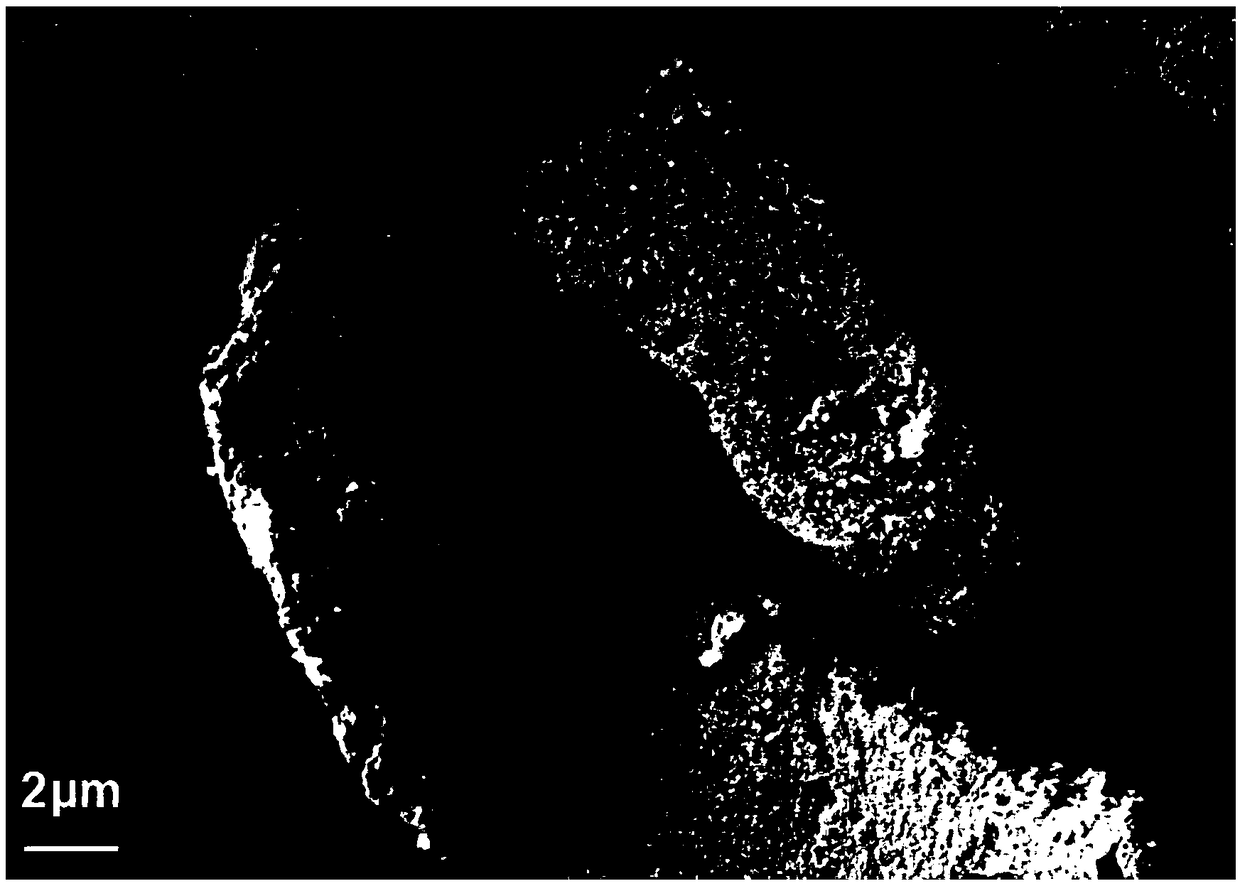

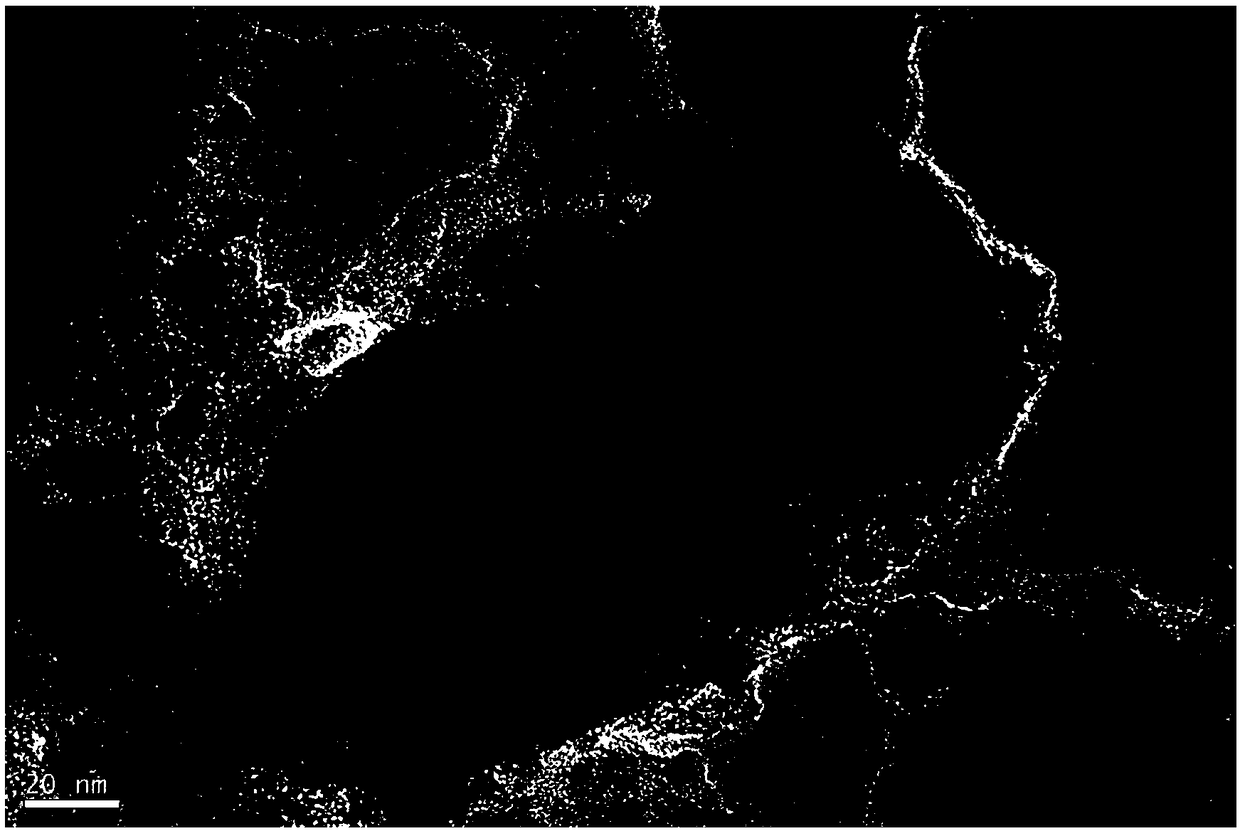

[0036] S1: According to the mass ratio of 1:(1~5), the nano titanium dioxide (TiO 2 ) And silicon (Si) powder are added to a dispersion medium such as an ethanol solution, and then subjected to ultrasonic dispersion treatment, and then ball milling. The nano TiO 2 It is an anatase type with a particle size of 5-20 nm, and the particle size of the Si is nano-scale 30-200 nm or commercial micron-scale 5-100 μm.

[0037] S2: Add the GO...

Embodiment 1

[0048] In this example, Si / TiO modified with organic acid was prepared 2 The specific steps of / rGO@C lithium ion battery anode material are as follows:

[0049] S0: Prepare GO by the modified Hummer method: add 0.6g of flake graphite to a 200mL beaker containing 23mL of concentrated sulfuric acid, stir for 30min in an ice bath, and then slowly add 2.4g of KMnO 4 , Keep stirring for 1 hour and then heat in a water bath. After the temperature rises to 40℃, continue to stir for 30 minutes, slowly add deionized water to dilute to 50-60 mL, stir for 30 minutes and add appropriate amount of H 2 O 2 After stirring for 30 minutes, the obtained solution was washed by centrifugation and dried for 24 hours to obtain GO. Then GO was added to ethanol, and then subjected to ultrasonic dispersion treatment to make a uniform GO dispersion with a concentration of 1 mg / mL, and then the GO dispersion was treated with a cell pulverizer for 10 minutes before use.

[0050] S1: Weigh 2g of nano-Si with a...

Embodiment 2

[0057] In this example, Si / TiO modified with organic acid was prepared 2 The specific steps of / rGO@C lithium ion battery anode material are as follows:

[0058] S0: Prepare GO by the modified Hummer method: add 0.6g of flake graphite to a 200mL beaker containing 23mL of concentrated sulfuric acid, stir for 30min in an ice bath, and then slowly add 2.4g of KMnO 4 , Keep stirring for 1 hour and then heat in a water bath. After the temperature rises to 40℃, continue to stir for 30 minutes, slowly add deionized water to dilute to 50-60 mL, stir for 30 minutes and add appropriate amount of H 2 O 2 After stirring for 30 minutes, the obtained solution was washed by centrifugation and dried for 24 hours to obtain GO. Then GO was added to ethanol, and then subjected to ultrasonic dispersion treatment to make a uniform GO dispersion with a concentration of 1 mg / mL, and then the GO dispersion was treated with a cell pulverizer for 10 minutes before use.

[0059] S1: Weigh 2g of nano-Si with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com