Electrolytic cell with enlarged active membrane surface

A technology of electrolytic cell and diaphragm, which is applied in the field of electrolytic cell and can solve problems such as short circuit of diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

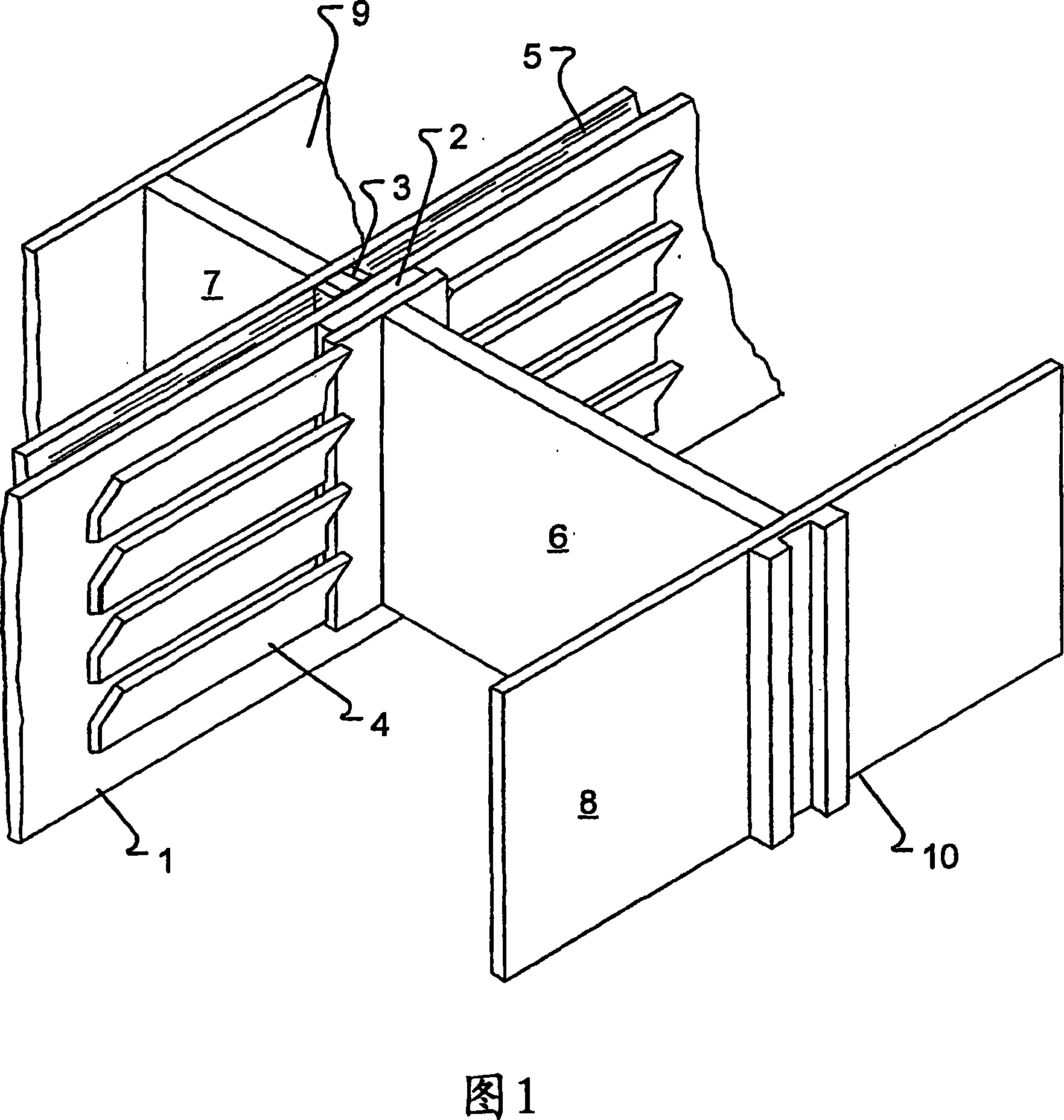

[0017] Figure 1 shows some internal parts in a perspective view of an electrolytic cell according to the invention. Diaphragm 1 is clamped between spacers 2 and 3 in direct contact with it. The anode 4 is pressed firmly against the anode 4 by the spacer element 2 welded on the back side to the elongated strip 6 . This strip is welded at its corners to the housing wall 8 of the half-container. On the half-container shell wall 8, along the height of the elongated strip 6, a contact strip 10 is arranged, in this case making the contact strip 10 groove-shaped and accommodating the contact strip adjoining the electrolytic cell (not shown in the figure) .

[0018] The structure of the cathode side is similar, so that the cathode 5 is in direct contact with the spacer element 3 welded to the elongated strip 7 on the rear side. The spacer element 3 is provided with openings as shown in detail in FIG. 3 . The elongated strip 7 is welded to the housing half wall 8 in its corners.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com